jad01

New member

I am doing a light refresh on my '84 RS, and have the the fork sliders off to clean up, replace seals, etc. I am taking a handful of parts to get powder coated, and was planning to get the sliders done as well.

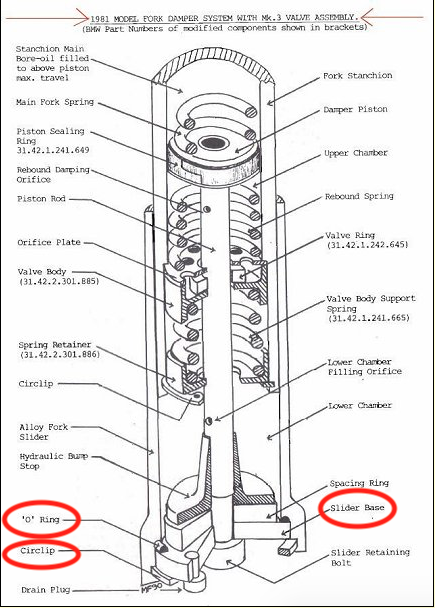

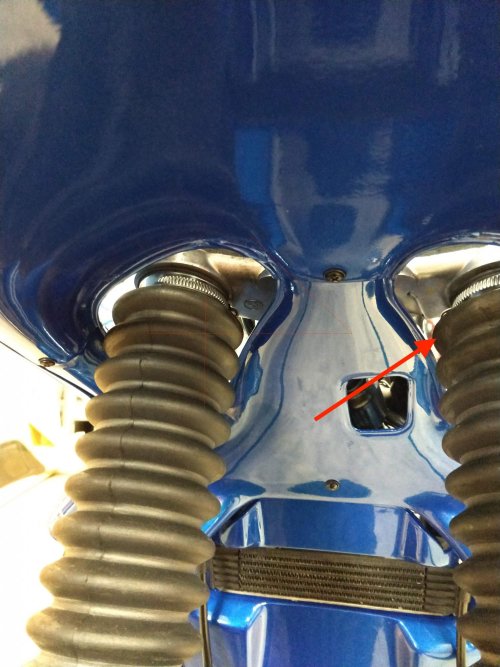

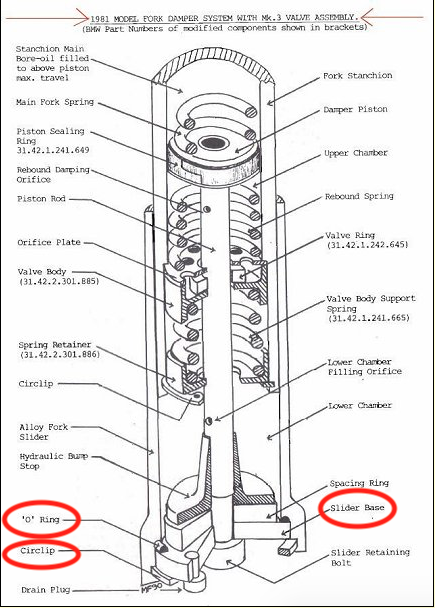

My question has to do with the base plate on the slider. It is held in place with a circlip (see pic), and then under it is an aluminum plate sealed in the lower with an o-ring (see diagram from Snowbum's site). The circlip comes out easily enough, but I'm concerned about breaking the seal on the plate as I don't see the o-ring on the parts fiche and want to be able to replace it with the right size and material.

I'm wondering if I should just leave it in place and take the slider to get powder coated as is (they tape everything off that doesn't get coated), or if I should venture to pull the plate out. It seals up fine currently, so I'm fine to leave sleeping dogs alone, but I'm curious if the heat used when they cure the powder would damage the o-ring (which I'm guessing is original and geologically converted to some form of metamorphic rock ) and create a leak that would require replacement anyway?

) and create a leak that would require replacement anyway?

I also considered just painting the sliders, but prefer the durability of powder coat. Any insight on further dissembling the slider base plate from the slider, the o-ring source and size, or if disassembly is a fool's errand would be appreciated.

My question has to do with the base plate on the slider. It is held in place with a circlip (see pic), and then under it is an aluminum plate sealed in the lower with an o-ring (see diagram from Snowbum's site). The circlip comes out easily enough, but I'm concerned about breaking the seal on the plate as I don't see the o-ring on the parts fiche and want to be able to replace it with the right size and material.

I'm wondering if I should just leave it in place and take the slider to get powder coated as is (they tape everything off that doesn't get coated), or if I should venture to pull the plate out. It seals up fine currently, so I'm fine to leave sleeping dogs alone, but I'm curious if the heat used when they cure the powder would damage the o-ring (which I'm guessing is original and geologically converted to some form of metamorphic rock

) and create a leak that would require replacement anyway?

) and create a leak that would require replacement anyway?

I also considered just painting the sliders, but prefer the durability of powder coat. Any insight on further dissembling the slider base plate from the slider, the o-ring source and size, or if disassembly is a fool's errand would be appreciated.