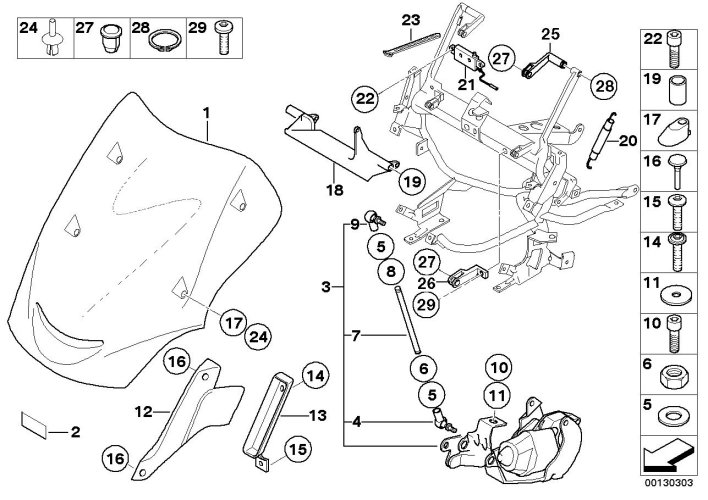

I'm wondering if anyone is or knows a machinist who might be able to fabricate a steel version of BMW Part no. 46 63 7658866 (Microfiche 46_0814). It's calle a "lever", and it goes on the windshield mechanism on my 2003 K1200GT. It's made of pot metal, costs $60+ and breaks easily. Tired of replacing it. If someone already makes these, so much the better. Thanks in advance.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machinist for windshield lever

- Thread starter lljanssen

- Start date

dieselyoda

Active member

Unfortunately, the economics aren't there to save any money. Set up time for one piece or even a few is just too costly.

I would this kind of project for the winter.

I would this kind of project for the winter.

mikegalbicka

Back in the saddle again

If it is #26, have a look through here for something that may match up-

https://www.westmarine.com/sailing-shackles-snaps-fittings

“One-of” gets rather involved and usually needs a good one to copy. If you want to try making one on your own, a piece of Delrin or even UHMW plastic can be easily manipulated with hand tools and is amazingly durable.I'm wondering if anyone is or knows a machinist who might be able to fabricate a steel version of BMW Part no. 46 63 7658866 (Microfiche 46_0814). It's calle a "lever", and it goes on the windshield mechanism on my 2003 K1200GT. It's made of pot metal, costs $60+ and breaks easily. Tired of replacing it. If someone already makes these, so much the better. Thanks in advance.

OM

mikegalbicka

Back in the saddle again

I bought better windshield support arms for my 07RT from this company. The BMW parts had the same problem with breaking easily. Perhaps they can help.

http://westtoolff.com/

http://westtoolff.com/

36654

New member

I bought better windshield support arms for my 07RT from this company. The BMW parts had the same problem with breaking easily. Perhaps they can help.

http://westtoolff.com/

Was that an existing product line for them or a one-off product you special ordered?

mikegalbicka

Back in the saddle again

Was that an existing product line for them or a one-off product you special ordered?

Existing. Call to see if they already make this. If not and there is a market they might be interested. They might offer a quote for a one off as well.

Last edited:

I worked in a machine shop in a previous life and these days I have a few tools in the shop, but no lathe or mill. I have had success making small "one of" parts like this. I pick up a appropriate piece of aluminum bar stock and hacksaw off the major pieces then file it to finished size and drill the holes in my drill press. Also, you can cut aluminum with wood working tools. I cut aluminum plate with my table saw and a standard carbide blade, and have used my router to chamfer and round over edges. Wear eye protection! Aluminum slivers fly everywhere!

36654

New member

As I drift back in time to my working days. The NRE and capital equipment cost to make something happen has to occur before the first prototype goes to production.

I'm with 'yoda on this one, find a salvage part or buy a new one. At $60 per item, that's no more than 1-hr of machinist's time (fully burdened, of course) and way less than any BMW hourly shop rate.

I'm with 'yoda on this one, find a salvage part or buy a new one. At $60 per item, that's no more than 1-hr of machinist's time (fully burdened, of course) and way less than any BMW hourly shop rate.

Depends on how often he has to replace it, seems like in his first post he has replaced a few.

Even if you have to pay twice the price, but get a billet piece that never breaks again it may be worth it.

Sometimes replacing a part like this with something stronger you will find the next part in line that breaks and the $60 part was cheap!

Like hopping up a car. Build the engine and the transmission can't take the abuse. replace the transmission with something better and the driveshaft can't handle. Replace the driveshaft with a beefier part and the rear end fails....

Even if you have to pay twice the price, but get a billet piece that never breaks again it may be worth it.

Sometimes replacing a part like this with something stronger you will find the next part in line that breaks and the $60 part was cheap!

Like hopping up a car. Build the engine and the transmission can't take the abuse. replace the transmission with something better and the driveshaft can't handle. Replace the driveshaft with a beefier part and the rear end fails....

pglaves

#13338

So let me pose a question: Have other owners of this model had breakage of this part. And if they did, have they had repeat breakage. If so speak up because I haven't heard anythingabout it until this thread?

Or is it possible that some other defect with the system on the OP bike is causing this piece to break?

Or is it possible that some other defect with the system on the OP bike is causing this piece to break?

52184

GTRider

So let me pose a question: Have other owners of this model had breakage of this part. And if they did, have they had repeat breakage. If so speak up because I haven't heard anythingabout it until this thread?

Or is it possible that some other defect with the system on the OP bike is causing this piece to break?

I’ve not broken any in 100k+ on the ‘04 GT. I run a tall aftermarket windscreen that puts more loading on those arms and have had no issues. But, I don’t generally raise/lower the screen under way or if I do, it’s lowered while going through towns or traffic and is raised again before hitting highway speeds. I do that simply because I don’t have a lot of faith in what I consider to be a somewhat poorly designed system.

Best,

DeVern

lkchris

Active member

I'm wondering if anyone is or knows a machinist who might be able to fabricate a steel version of BMW Part no. 46 63 7658866 (Microfiche 46_0814). It's calle a "lever", and it goes on the windshield mechanism on my 2003 K1200GT. It's made of pot metal, costs $60+ and breaks easily. Tired of replacing it. If someone already makes these, so much the better. Thanks in advance.

It breaks easily because it's designed to break easily ... when you go over the handlebars and into the windshield. That's a safety thing.

Yours likely breaks because you have a larger than original windscreen fitted. (And you ride fast!) From seeing lots of posts, this appears fairly common.

BMW started this safety idea with its first fairing, the R90S fairing. It was fitted with push rivets ... which lots of guys replaced with nuts and bolts, thus also losing the safety factor.

Thanks and further info

Thanks to all who replied. A couple additional bits of information: bike has been dropped a couple times over its lifetime, both breaking the subject part (lever) on the right side and bending the upright support piece it attaches to. I eyeball straightened the upright the first time and ran with a tall Aeroflow screen for years and maybe 90-100K miles with no problem. (Note: I do tend to go really fast). After last drop the Aeroflow broke, replaced and it broke again. With the following replacement I changed to a tall Parabellum screen, and also replaced the "shaft" (#18 on same fiche, PN 46 63 7670508) the lever attaches to because was also broken. Again, I eyeball straightened the upright and thought I was all set, then the same lever broke again.

I agree there may be an underlying problem causing the lever to break (maybe poor eyeball straightening), but I'm not bright enough to figure out what it is. I suspect if I replaced the entire fairing bracket ($1040) the problem may well go away, but that's a lot to spend on a bike with 162000 (one owner!) miles on it. I welcome any other suggestions. Thanks again.

Thanks to all who replied. A couple additional bits of information: bike has been dropped a couple times over its lifetime, both breaking the subject part (lever) on the right side and bending the upright support piece it attaches to. I eyeball straightened the upright the first time and ran with a tall Aeroflow screen for years and maybe 90-100K miles with no problem. (Note: I do tend to go really fast). After last drop the Aeroflow broke, replaced and it broke again. With the following replacement I changed to a tall Parabellum screen, and also replaced the "shaft" (#18 on same fiche, PN 46 63 7670508) the lever attaches to because was also broken. Again, I eyeball straightened the upright and thought I was all set, then the same lever broke again.

I agree there may be an underlying problem causing the lever to break (maybe poor eyeball straightening), but I'm not bright enough to figure out what it is. I suspect if I replaced the entire fairing bracket ($1040) the problem may well go away, but that's a lot to spend on a bike with 162000 (one owner!) miles on it. I welcome any other suggestions. Thanks again.

36654

New member

Thanks to all who replied. A couple additional bits of information: bike has been dropped a couple times over its lifetime, both breaking the subject part (lever) on the right side and bending the upright support piece it attaches to. I eyeball straightened the upright the first time and ran with a tall Aeroflow screen for years and maybe 90-100K miles with no problem. (Note: I do tend to go really fast). After last drop the Aeroflow broke, replaced and it broke again. With the following replacement I changed to a tall Parabellum screen, and also replaced the "shaft" (#18 on same fiche, PN 46 63 7670508) the lever attaches to because was also broken. Again, I eyeball straightened the upright and thought I was all set, then the same lever broke again.

I agree there may be an underlying problem causing the lever to break (maybe poor eyeball straightening), but I'm not bright enough to figure out what it is. I suspect if I replaced the entire fairing bracket ($1040) the problem may well go away, but that's a lot to spend on a bike with 162000 (one owner!) miles on it. I welcome any other suggestions. Thanks again.

Before buying a new bracket, I would search ebay for salvage parts. While I can't find the lever item, there's a few servo motor and bracket assemblies listed.