Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1977 r100/7 get output flange off trans ?

- Thread starter tbroad5

- Start date

This is held on with some massive torque...something like 160-170 ft-lbs. In the Nov 2014 Owners News, Matt Parkhouse discusses how to get this off. You need one heck of a breaker bar and some special tools...I don't think a puller is the way to go...it's a tapered fit. Cycleworks.Net has a setup for this:

https://www.cycleworks.net/index.ph...id=321&zenid=ee82e4966f34bdd07e74ce5fba065a77

https://www.cycleworks.net/index.ph...id=321&zenid=ee82e4966f34bdd07e74ce5fba065a77

pglaves

#13338

Looks like the engine put out way too much torque to me.

Paul, my memory is slowly failing. Back around ‘90 I was riding the R90 on a regular basis. But it was a little bit of a touring rat bike. I decided on a economy rebuild, my phrase for the rebuild. Turn the bike into what I called a BMW version of a Moto Guzzi Eldorado. I had a plan to do a fairly cheap rebuild. I had already accumulated most of the parts to be exchanged. Several friends took mercy on me to donate their skills pro bono. During disassembly got the trans out. As I was carrying it around, I heard the sound of metal junk

clunking around inside. Oh no! What the h___. Redoing the gearbox was not on the rebuild list. Disgust, dispair and agony on me. Took it over to my Beemer tech and showed him. He shook it around and it sounded like marbles banging around. Not good little buddy. He said drain the gearbox, maybe something will fall out the drain plug. Got a bucket, drained the oil, out fell a dog gear.

clunking around inside. Oh no! What the h___. Redoing the gearbox was not on the rebuild list. Disgust, dispair and agony on me. Took it over to my Beemer tech and showed him. He shook it around and it sounded like marbles banging around. Not good little buddy. He said drain the gearbox, maybe something will fall out the drain plug. Got a bucket, drained the oil, out fell a dog gear.

Leo Goff my tech said we gotta open up your gearbox and my tool to do that is being used by a buddy of mine. I grabbed the box flipped it around and looked at the rear of it. Damn thing is like vault safe. Leo this thing needs a door to open and l get access. Yea it’s mess, break loose the big nut, remove all the rear bolts, heat the case, then remove it. Use the puller. Remove the that piece. Yadayadayada. The guy that designed this must have been a sadist. Leo had a pretty good basic machine shop and a good pile of spare scrap metal. Leo, I’ll make the tool. Go ahead Barry, help yourself. Looked in a shop manual and at a pic of BMW shop tool. Grabbed a 6” scale and started eyeballing the back of the trans. Grabbed some cast off metal and chucked one in the lathe and the chips were flying. Leo was watching and smilin. A few hours later I handed him the trans. tool; weld this handle on for me.

stevenrankin

Active member

Devils advocate

So, just being a bit of a jerk here, Someone is looking to rebuild a gear box? All of the BMW mechanics I know trained by the factory and lots of experience ingrained into my head don't mess with a BMW gear box if you don't have the proper tools to do the job.

This not only means not having the tool to remove the output flange but anything else. For example proper tools need to shim things inside the box.

Its your bike, and I can understand the desire to work on it as much yourself as possible however, just because one person you know or know of rebuilt their gear box and didn't have further problems down the road doesn't mean they did the job right.

Before my independent shop became an independent shop, I was privileged to hang around befriend the mechanics at my now long gone BMW dealership. Now, I hang around an independent shop which has had two owners the first retiring after working at the closed dealership. The second owner being trained by the first.

I have seen a lot of jobs come in from well meaning but unknowing or unskilled people who have done their own work. Sometimes it is a cheap fix, other not so.

Yeah yeah, I am being a jerk here, but for a good reason. Some times the cheap comes out expensive. Sometimes we exceed our skills and knowledge and things turn out bad.

Now other members of the forum, don't beat on me regarding this, I am by no means an expert on airhead mechanics, I know my own experience and mistakes I have made. I also see a lot of stuff done by "expert airhead mechanics" which is great and shameful.

So, just being a bit of a jerk here, Someone is looking to rebuild a gear box? All of the BMW mechanics I know trained by the factory and lots of experience ingrained into my head don't mess with a BMW gear box if you don't have the proper tools to do the job.

This not only means not having the tool to remove the output flange but anything else. For example proper tools need to shim things inside the box.

Its your bike, and I can understand the desire to work on it as much yourself as possible however, just because one person you know or know of rebuilt their gear box and didn't have further problems down the road doesn't mean they did the job right.

Before my independent shop became an independent shop, I was privileged to hang around befriend the mechanics at my now long gone BMW dealership. Now, I hang around an independent shop which has had two owners the first retiring after working at the closed dealership. The second owner being trained by the first.

I have seen a lot of jobs come in from well meaning but unknowing or unskilled people who have done their own work. Sometimes it is a cheap fix, other not so.

Yeah yeah, I am being a jerk here, but for a good reason. Some times the cheap comes out expensive. Sometimes we exceed our skills and knowledge and things turn out bad.

Now other members of the forum, don't beat on me regarding this, I am by no means an expert on airhead mechanics, I know my own experience and mistakes I have made. I also see a lot of stuff done by "expert airhead mechanics" which is great and shameful.

What did Dirty Harry say? A man’s gotta know his limitations. I happen to know a few guys who can do the work. All are highly intelligent in the automotive, motorcycle and related industries. Leo Goff, Ron Wiginton, Eddie Wilbanks, Paul Kosma, Marshall Robilio, and theirs a few more, who I can’t remember their names at the moment. One is a retired high ranking GM engineer. He told me he had never seen such a group of guys out side of Detroit. I told him, yep pretty unbelievable; but true. I’m by far the dumbest of the bunch. I don’t even put myself on the list. I’m just a pedestrian. But they like and tolerate me for the most.

Looks like that bearing on the right side of the photo should be replaced too...

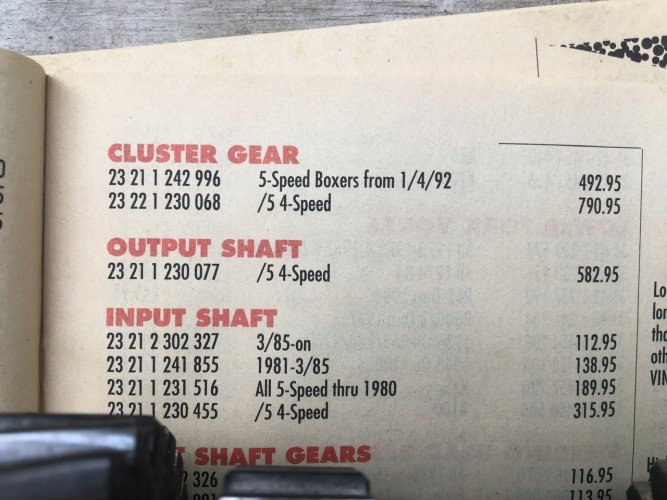

Good eye. I think several bearings were replaced, all gaskets and seals and the upgraded BMW shift kit was also installed. I watched Leo deconstruct the tranny, pull the pieces out, along with the shims and tie wrap them together. I remember him running the bearings around in his hands. Setting them aside and checking the next one. Then he got a notebook out and made the needed parts list. Your not going to like this, Barry. Not good seeing a grown man cry. I reached over and grabbed a current Capital Cycle catalog. The crying, bellowing, wailing continued loudly. Leo, handed me a shop towel; get a grip.

Found this Capital Cycle catalog kinda close to when I had the trans. fixed.

I believe the last time I saw a cluster gear For a /6 it was around $600/700. Leo found me a good used one. I believe it was $250. I think every thing else, bearings, seals, gaskets, etc. was also about $250. I watched Leo reassemble the gearbox. It was an impressive display of tech ability. After he had the box sealed back up, he hooked up the tranny to an fixture and run it thru all the gears up and down. Unhooked it, looked over at me and said U Probably got a better gearbox now than when it was new. 30,000 miles later, it pretty much confirmed it. Thx Leo.

Looks like the engine put out way too much torque to me.

The early 5 speed transmission had a flaw. The dogs were cast forged and not precision machined to size. The mating of dogs were hit and miss. A few matched up well enough, but the design was problematic. This defect was all through the ‘74 model year and part of the ‘75 year. Some where along in the ‘75 model year BMW started machining the dogs to size and this solved that problem for the most part. This defect was also in R60/6, R75/6, R90/6, and the hallowed R90S.

stevenrankin

Active member

If people don't write

If people don't write in the forum, we don't learn. A lot of threads get off topic or hijacked from time to time. MOA has a great moderator, he will tell you if you need to cease and desist. LOL. St.

If people don't write in the forum, we don't learn. A lot of threads get off topic or hijacked from time to time. MOA has a great moderator, he will tell you if you need to cease and desist. LOL. St.

:

:

Oh well.

Oh well. That’s why I’m not on the list.

That’s why I’m not on the list.