Well, I am going in deep. Full spline lube. (I have very complete dealer records, but no spline lube mentioned) Have the rear drive, swing arm, and tranny on the floor. Everything looks good, all seals not leaking. Splines look great, some original grease still present. (that red stuff the factory used sure looks like rust at first..) Clutch boot has some misting, so will replace it as well. So far I haven't pulled the clutch, but it was fine riding. Bike has 12K miles (1990) Will do a full fluid change etc. Starter, alternator seems fine, no issues that I can see. While I am down this deep is there anything else I should look at? It looks like the swing arm bearings are sealed, not like the airhead types. The movement is smooth so I will leave them alone. Just hoping not to have any "dang I should have".. moments)

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

K75s Maintenance

- Thread starter smithrjd

- Start date

-

- Tags

- bolt torque torque chart

mcmlcccvrs

New member

When I did the spline lube on my 1985 K100RS I pulled the clutch because I wanted to inspect everything and measure the thickness of the clutch disc. I also lubed those splines sparingly as you don't want any of the lube to migrate onto the friction plate. I am also a fan of anti-seize compound during reassembly. Every bolt I ever touched on my bike was completely dry and they all got reinstalled with Copper Coat anti seize compound.

I will give the center and side stand some attention. All of the bolts were dry, will use some anticize when it goes back together. A drip of oil from the famous "weep hole", no antifreeze. Hopefully OK, had to replace the oil/water pump on my other K75's and the K100. Them things are expensive.

Just a few things to consider. I think they are important.

Definitely mark all clutch components for reassembly as they are balanced. (Clutch Plate and Friction Rings)

Personal procedures:

I use new (6) assembly bolts and lock washers on the clutch assembly.

I also lightly lube the back perimeter of the pressure plate that contacts the large ring spring in the Flywheel as well as the brass or bronze center bushing where the clutch rod pushes on the plate.(and the end of the Rod also).

I take a sharp pencil and before disassembling the clutch assembly mark the clutch plate center position. (Inside of the friction ring)

This is more accurate than my clutch centering tool. Hold the pencil at the same angle while marking and it will be far better than guessing at reassembly time.

READ EVERYTHING you can on this forum as there is lots of information here on this topic.

I’ll look for photo of the method I use to reinstall the transmission. One man job and hands free pause if necessary. (The Search engine has something against me.)

Charlie

Definitely mark all clutch components for reassembly as they are balanced. (Clutch Plate and Friction Rings)

Personal procedures:

I use new (6) assembly bolts and lock washers on the clutch assembly.

I also lightly lube the back perimeter of the pressure plate that contacts the large ring spring in the Flywheel as well as the brass or bronze center bushing where the clutch rod pushes on the plate.(and the end of the Rod also).

I take a sharp pencil and before disassembling the clutch assembly mark the clutch plate center position. (Inside of the friction ring)

This is more accurate than my clutch centering tool. Hold the pencil at the same angle while marking and it will be far better than guessing at reassembly time.

READ EVERYTHING you can on this forum as there is lots of information here on this topic.

I’ll look for photo of the method I use to reinstall the transmission. One man job and hands free pause if necessary. (The Search engine has something against me.)

Charlie

At only 12K miles I think I am going to leave the clutch alone. Plenty of travel and it "bit" in the center of travel not towards the end. I used some M8 long threaded rods to support the tranny when I removed it, and will do the same when I put it back in. Will grease the ends of the clutch rod. Too bad, only about 900 miles since the last service, (and tires) but it was 6 years ago, so a fluid change and new tires. I am going to replace the brake lines with stainless, so will flush then. Coolant was replaced and system flushed at 6 years ago as well. Hoses seem fine, still supple. Debating on another flush. The brakes seem a bit mushy, but my last one sold to get this one was a 2002 K1200RS, with basically power brakes.. Might just be me on the brake feel. I was really happy to find this one, about a museum piece. No corrosion on any of the bolts and clamps. Looks new.

don't use anti-seize. there is a TQ spec for every bolt and anti-seize leaves everything looser than it should be.

use BLUE LOCKTITE.

I think it's the opposite.

The anti-seize acts as a lubricant, and allows the bolt to continue to rotate where a dry bolt would be at full torque.

The risk is over tightening the assembly.

pglaves

#13338

I think it's the opposite.

The anti-seize acts as a lubricant, and allows the bolt to continue to rotate where a dry bolt would be at full torque.

The risk is over tightening the assembly.

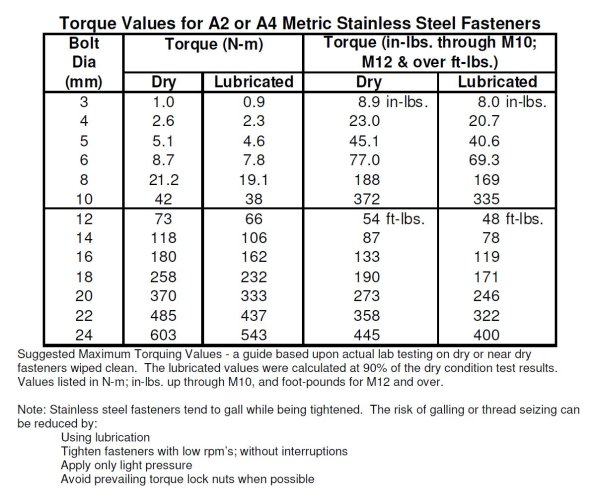

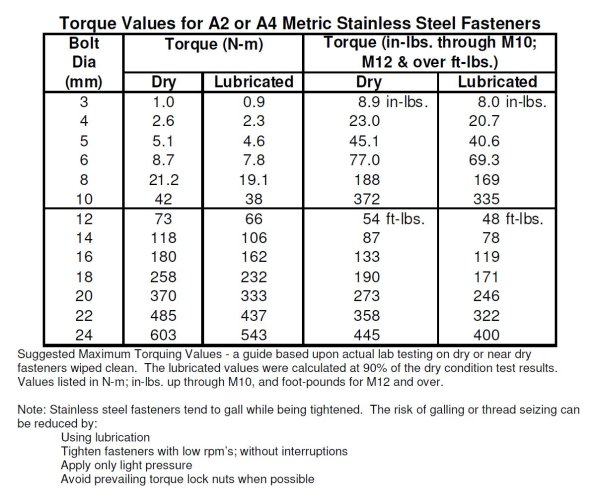

I agree. To get the same clamping force the torque needs to be reduced approximately 25%, plus or minus depending on thread pitch.

There are two forces serving to resist turning the fastener. One is the clamping force and the other is thread friction. Since a lubricant reduces thread friction a portion of this contribution to resistance to turning needs to be subtracted.

Here is a table from fastenal that gives general torque values for lubricated and non-lubricated metric fasteners -

Links to the above table and other information regarding fastener torque and the effects of lubrication -

https://www.fastenal.com/content/feds/pdf/Torque of Metric Stainless Steel.pdf

https://www.hextechnology.com/articles/bolt-lubricant-torque/

https://www.engineeringtoolbox.com/torque-lubrication-effects-d_1693.html

https://engineeringlibrary.org/reference/fastener-torque-nasa-design-manual

Links to the above table and other information regarding fastener torque and the effects of lubrication -

https://www.fastenal.com/content/feds/pdf/Torque of Metric Stainless Steel.pdf

https://www.hextechnology.com/articles/bolt-lubricant-torque/

https://www.engineeringtoolbox.com/torque-lubrication-effects-d_1693.html

https://engineeringlibrary.org/reference/fastener-torque-nasa-design-manual

Similar threads

- Replies

- 7

- Views

- 1K