beardyobeards

New member

Hey All,

I bought a 1979 BMW RE80/7 with 65k miles up on it last year with the goal of stripping it down to each individual component and rebuilding it again. I've been a long time BMW owner but this is my first airhead and the first project of this magnitude I've ever taken on. Really excited about this rebuild

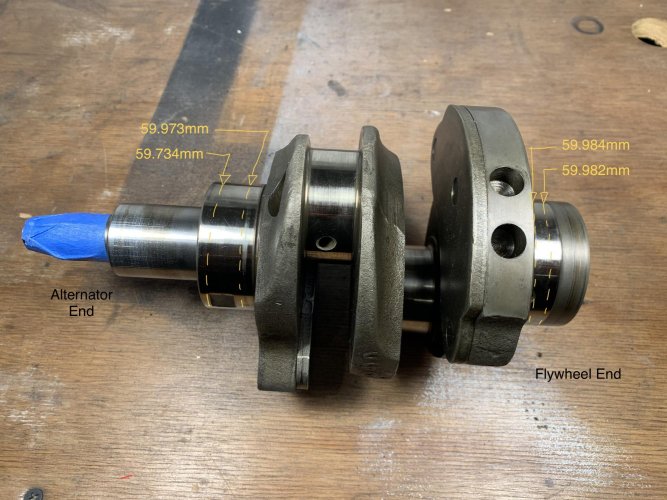

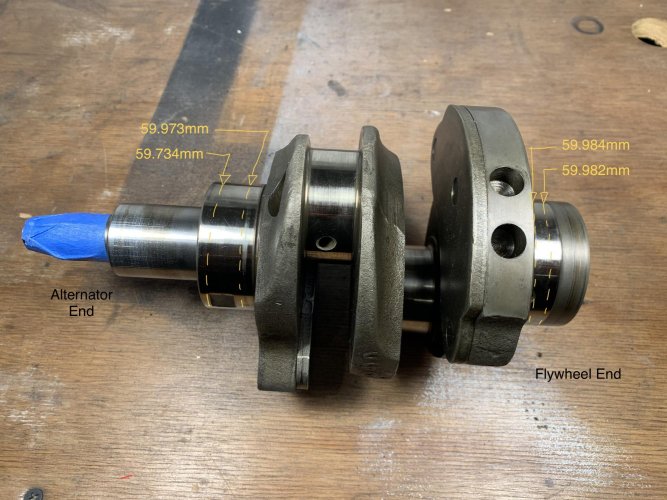

I'm at the point where I'm starting to rebuild and I have a couple of questions for some of the experts out there (@brook reams if you have time?) The first step is installing the crank shaft back into the case but before I do, I'd like some advice about checking the main journals for wear in order to figure out which main bush bearings to order. Looking at the journals there are some linear markings but feel smooth and seem "good enough" to my untrained eyes but could someone with a better eye please have a look and see what you think?

I've also got some photographs of the connecting rod journals. Definitely lots of small nicks there, but hoping again they're "good enough" to get by without a regrind. What do you think - a little buffing good enough for these?

My main concern of all is with the wear on the main journal diameters. See the diagram, but I am basically getting a taper of >0.2mm on the Alternator end. From reading my Clymer manual I believe this means its time to grind down a size to level everything out, but wondering if anyone has experience with this? The bushing is in a terrible state (see photo).

Any advice would be much appreciated on all of this. It's the first step in the build for me and I want to do things right. If you have any advice - or you recommend that I ship it off to an expert, please add a reference. I live in California

Thanks in advance folks.

Beardy

I bought a 1979 BMW RE80/7 with 65k miles up on it last year with the goal of stripping it down to each individual component and rebuilding it again. I've been a long time BMW owner but this is my first airhead and the first project of this magnitude I've ever taken on. Really excited about this rebuild

I'm at the point where I'm starting to rebuild and I have a couple of questions for some of the experts out there (@brook reams if you have time?) The first step is installing the crank shaft back into the case but before I do, I'd like some advice about checking the main journals for wear in order to figure out which main bush bearings to order. Looking at the journals there are some linear markings but feel smooth and seem "good enough" to my untrained eyes but could someone with a better eye please have a look and see what you think?

I've also got some photographs of the connecting rod journals. Definitely lots of small nicks there, but hoping again they're "good enough" to get by without a regrind. What do you think - a little buffing good enough for these?

My main concern of all is with the wear on the main journal diameters. See the diagram, but I am basically getting a taper of >0.2mm on the Alternator end. From reading my Clymer manual I believe this means its time to grind down a size to level everything out, but wondering if anyone has experience with this? The bushing is in a terrible state (see photo).

Any advice would be much appreciated on all of this. It's the first step in the build for me and I want to do things right. If you have any advice - or you recommend that I ship it off to an expert, please add a reference. I live in California

Thanks in advance folks.

Beardy