Scarletswirl

New member

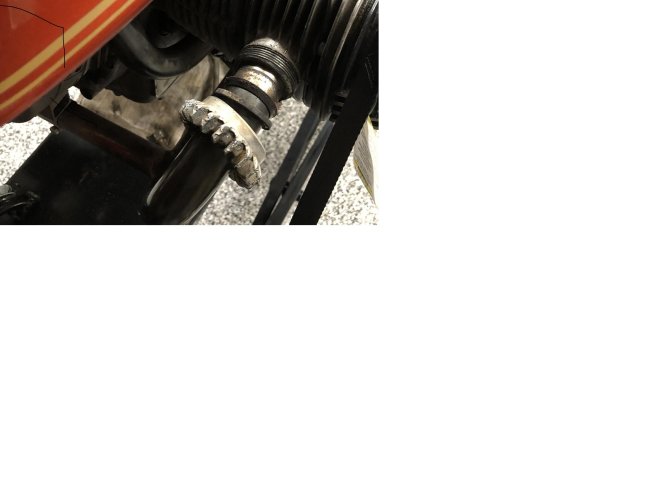

I just acquired an '89 with a little over 40K miles. I need to reseal the pushrods, but I'm having trouble removing the exhaust nuts, which is the first step. All I've read so far indicates that if they are stuck, cutting them off is the only way out.

1. At what point should I give up and call them 'stuck'? In other words, are there tips and techniques that can be used to loosen these nuts, besides brute force?

2. Is this (i.e. exhaust nut cut-off) something any of you who are not professional mechanics tried successfully. I would hate to do anything that will result in permanent damage.

All thoughts and ideas appreciated

Thanks

Marc

1. At what point should I give up and call them 'stuck'? In other words, are there tips and techniques that can be used to loosen these nuts, besides brute force?

2. Is this (i.e. exhaust nut cut-off) something any of you who are not professional mechanics tried successfully. I would hate to do anything that will result in permanent damage.

All thoughts and ideas appreciated

Thanks

Marc