Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2012 R1200R Damaged Oil Filter Spigot/Mount/Stud

- Thread starter aweesner

- Start date

First off, welcome to the forum

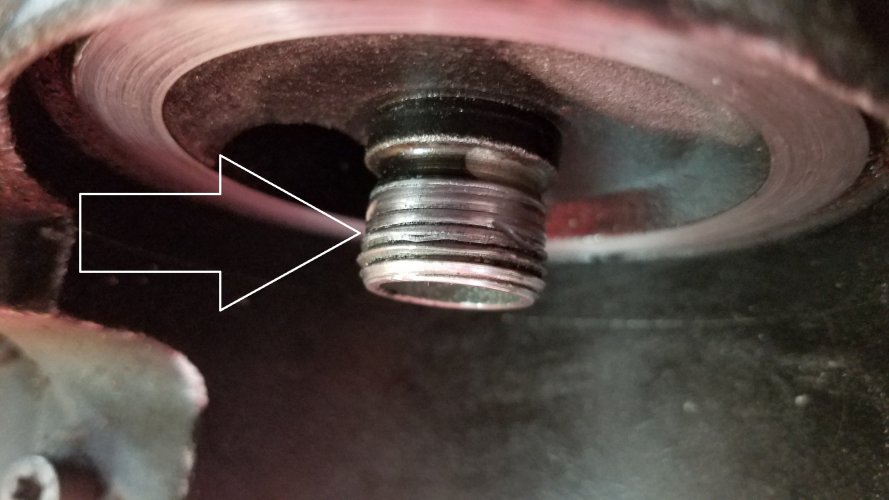

That is not a good thing to see. I looked at parts fiche and it isn’t clear if that is a separate part. Even if so, a case splitting endeavor.

I would take picture to a dealer and get the possible remedies. Folks have removed stuck filters before, but that is a new one to me.

Someone else may have a better take

That is not a good thing to see. I looked at parts fiche and it isn’t clear if that is a separate part. Even if so, a case splitting endeavor.

I would take picture to a dealer and get the possible remedies. Folks have removed stuck filters before, but that is a new one to me.

Someone else may have a better take

pglaves

#13338

Without polishing the horse apple this is either bad news or worse news. I do not think that stub can be replaced by just buying the part. If it can it will probably require that the engine case be split. Maybe with the engine out of the bike a very good machine shop can bore the damaged part out and cut threads and install a custom made replacement piece.

If that were my bike I would very carefully try to clean up those threads and install a new filter. There really ought not be a great deal of stress on those threads so this might work.

If that were my bike I would very carefully try to clean up those threads and install a new filter. There really ought not be a great deal of stress on those threads so this might work.

Last edited:

lee

Debbie's Servant

If that were my bike I would very carefully try to clean up those threads and install a new filter. There reeally ought not be a great deal of stress on those threads so this might work.

Looks like the first three, or the 2nd and 3rd thread may clean up enough to hold the filter.

I do not know how the threaded steel filter spigot is mounted on the R1200 motors, but aluminum blocks are common on cars and the spigot usually just threads into the block:

https://m.youtube.com/watch?v=6Sspezfxx_Y

If the spigot is not available from a dealer, there are several used/junk blocks on ebay. I would contact one of them about the part.

https://m.youtube.com/watch?v=6Sspezfxx_Y

If the spigot is not available from a dealer, there are several used/junk blocks on ebay. I would contact one of them about the part.

If I were in your boat, I would take a new filter to a bolt store and see what fits, and check on of the aftermarket oil filter thread specs, and compare results. Then I would buy that size thread chaser. If that doesn’t work maybe there are non metric filters with smaller tread diameter and you could re-thread the stub. I feel for your situation and hope the best for you.

wyman.winn

i should be out riding!

If it were me, i would measure the outside diameter of the thread, measure the thread pitch using a thread gauge and purchase the correct threading die from McMaster-Carr or other industrial supplier and EVER so gently repair the threads...yes, the die would be kinda pricey but WAY cheaper than the alternative...dies are on the order of $45 or so...

just my 2cents worth...

edit...a bit of digging and i find that the thread is 3/4-16...funny that a SAE thread would be on a metric bike...I would, of course, confirm before ordering a die...

lookie here... https://motorcycleinfo.calsci.com/FilterXRef.html#7

just my 2cents worth...

edit...a bit of digging and i find that the thread is 3/4-16...funny that a SAE thread would be on a metric bike...I would, of course, confirm before ordering a die...

lookie here... https://motorcycleinfo.calsci.com/FilterXRef.html#7

lee

Debbie's Servant

Looks like the first three, or the 2nd and 3rd thread may clean up enough to hold the filter.

I forgot this engine does not have a cover over the filter like a K bike Brick engine.

With only two threads if the filter blew off, all the oil would dump in front of the rear tire.

wyman.winn

i should be out riding!

I would not take a chance on a questionable repair on this. With the engine running there is 300-400 pounds trying to push off the filter. Like the previous post, if the filter falls off going down the road it might not end well.

the oil pressure relief valve is set to to open at 6.5bar ±1bar or between 80 and 110psi...

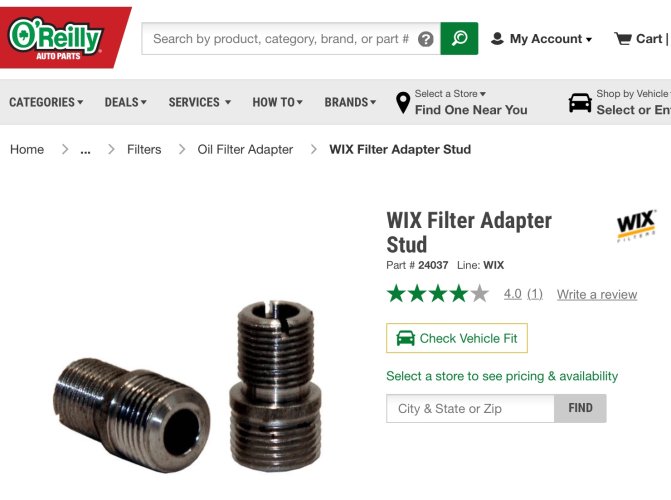

Looks like many filter studs are common size. Don’t know if this one fits, though :

https://www.amazon.com/WIX-Filters-24037-Filter-Adapter/dp/B000C9XYQG

https://www.amazon.com/WIX-Filters-24037-Filter-Adapter/dp/B000C9XYQG

Attachments

pglaves

#13338

It seems that these things are designed to be threaded in and out. The trick is how to unscrew the old one and screw in the new one. Check to see of there is an internal hex like for an 8mm or maybe 10mm allen wrench inside the bore of the stub. Then the trick becomes finding one to match the thread set that screws into the engine case.

I think it is time to consult a real good dealer tech who can chase the issue upstram with BMW tech if needed. We are guessing and I've been guessing wrong from the start.

I think it is time to consult a real good dealer tech who can chase the issue upstram with BMW tech if needed. We are guessing and I've been guessing wrong from the start.

gtrider

52184

Paul’s suggestion of having a dealer/tech chase this upstream with BMW is spot on. A couple of additional questions would be which threadlocker was used at the factory, and whether these are RH or LH threads going into the case. This would be a textbook scenario for using a LH thread. If there’s threadlocker involved it will be tough to get enough heat into the case without disassembly.

It would sure be nice if someone who has walked this path already could chime in, or someone with an old case that could do some hands-on research.

Best,

DeVern

It would sure be nice if someone who has walked this path already could chime in, or someone with an old case that could do some hands-on research.

Best,

DeVern