Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BMW Dry Clutch Configuration

- Thread starter bigbear

- Start date

-

- Tags

- clutch design

pglaves

#13338

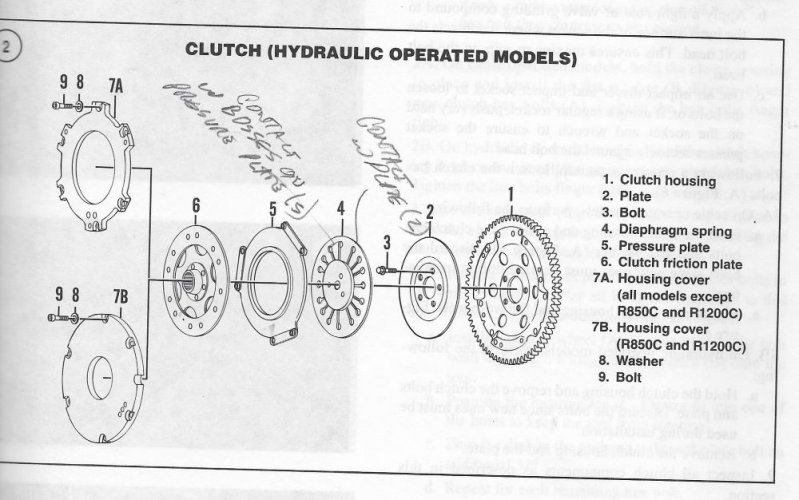

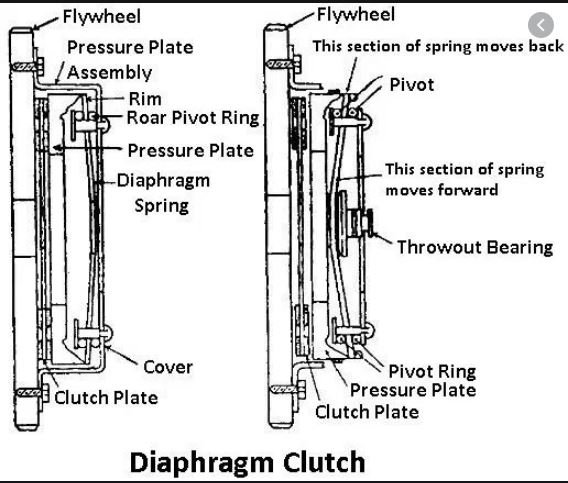

Just curious - any ideas why the BMW dry motorcycle clutch is configured differently than a typical auto clutch? Below are illustrations of oilhead clutch and typical auto clutch.

View attachment 78178

View attachment 78179

Well, I think the answer is simple. In most cars the pedal pulls the pressure plate away from the disk and on BMW motorcycles t pushes the pressure plate spring away from the disk.

It could be that the design was to ensure that the clutch disc would not engage to the flywheel. Advantage of this is when the clutch is replaced the flywheel would not have to machined flat due to wear. On the newer models the flywheel is now a piece of stamped steel called the clutch carrier. The flywheel on my /5 is solid steel like what is in a car or truck. Probably cost less to make a clutch carrier and lighter too.

beemerchuck

Member

Dry clutch design

I think it was just a packaging decision. By moving the diaphragm spring ahead of the clutch they could eliminate the normal release bearing and actuating arm. With the clutch release rod passing thru the input shaft it shorten the trans length considerably. With the small diameter rod it could ride directly on the spring without causing much wear. This allowed for the normal large throw out bearing to be much smaller and at the rear of the trans where it is easily serviced. Actually quire a brilliant packaging solution.

I think it was just a packaging decision. By moving the diaphragm spring ahead of the clutch they could eliminate the normal release bearing and actuating arm. With the clutch release rod passing thru the input shaft it shorten the trans length considerably. With the small diameter rod it could ride directly on the spring without causing much wear. This allowed for the normal large throw out bearing to be much smaller and at the rear of the trans where it is easily serviced. Actually quire a brilliant packaging solution.

pappy35

New member

I thought there was no throw out bearing on the clutch itself? The actuator rod applies no pressure to the spring plate when the clutch is disengaged (I get confused with this wording sometimes, I mean in-gear and driving the rear wheel). When engaged the slave cylinder has a bearing in it that the rod spins on. Is this correct?

beemerchuck

Member

Right, no throw out bearing in the clutch. It on the back end of the pushrod. In a housing on the trans rear cover on all cable operated clutches and in the slave cylinder of the hydraulic operated ones.