Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moly lube for spline shafts?

- Thread starter voisinen

- Start date

Welcome as well! There have been discussions about the discontinuation of a favorite spline lube, Honda Moly 60. Read some there:

https://forums.bmwmoa.org/showthread.php?78215-ATTENTION!!!-All-K-bikes-HONDA-MOLY-60-DISCONTINUED

Snowbum has additional discussion about spline lubricants on this page:

https://bmwmotorcycletech.info/chemicalsetc.htm

https://forums.bmwmoa.org/showthread.php?78215-ATTENTION!!!-All-K-bikes-HONDA-MOLY-60-DISCONTINUED

Snowbum has additional discussion about spline lubricants on this page:

https://bmwmotorcycletech.info/chemicalsetc.htm

pglaves

#13338

I use the PGlaves concoction of greases to lube my splines. I suspect he will be along soon to provide the formula.

Short Question - Long Answer (Short answer below in Bold)

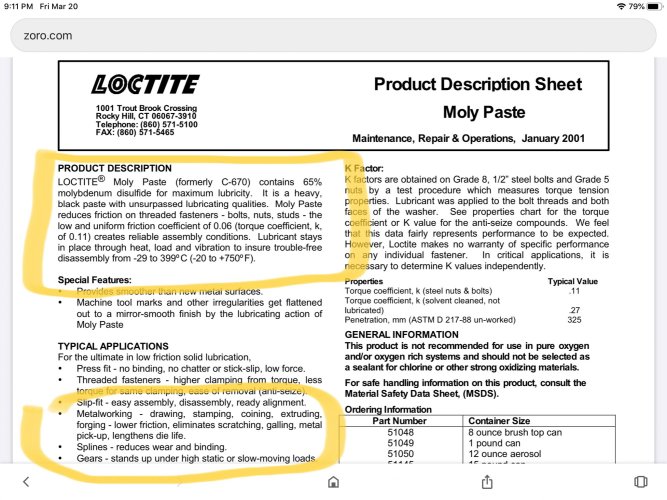

Basics: To be called a moly grease it must have a little moly. Most of what you find in the auto parts or hardware stores (such as the ubiquitous Sta-Lube brand) contain between 3% and 5% powdered molybdenum disulfide (moly) by volume. To be called a moly paste it must have at least 50% moly by volume.

The greases with 3 to 5 percent moly do not contain enough moly for splines. In my opinion most moly pastes lack certain key characteristics necessary for clutch and driveshaft splines. At least three key characteristics are important: 1) Anti-wear to protect against the sliding action of the splines. 2) Anti-corrosion to protect against oxidation. 3) Cushioning to protect the metal against the power pulses as the engine runs (fretting corrosion).

My experience with actual moly pastes such as Honda Moly 60 is that the 50% or more moly content does well for #1 but performs poorly on numbers 2 and 3. It also dries out too quickly in my opinion.

My original concoction took a moly paste and a very sticky water resistant grease and mixed them together 50%-50%. This was a mix of Honda Moly 60 and Wurth Sig 3000 grease. Because of all the advice to never "mix" greases, I let my first batch sit on the shelf all summer before I used it the following fall. I found no degradation so used it.

Now for some serendipity. I accidentally stumbled on the fact that a company known as TS Moly, an oilfield service company based in Houston sold a moly gear oil additive. Without fully doing my homework I mentioned this fact in a Benchwrenching column. About two weeks later I received a telephone call from a gentleman who was an executive with TS Moly. He told me that they had received several phone calls from people wishing to buy the additive. But he said that they sell the stuff in 55 gallon drums and 5 gallon pails and folks were wanting to buy pints and quarts. He asked if I thought there was a market for this among motorcyclists. I said yes and soon Guard Dog Moly Lubricants was born. It was a two or three person spin-off from TS Moly. Ben Mathes and I had several phone conversations and I met him once when he visited the Houston club rally.

One of our conversations migrated to discussing spline lube and I explained what I had been mixing together. Pretty soon GD-525 Moly Grease was on the market.

After a few years Ben Mathes retired and Guard Dog Moly Lubricants closed down. But the parent company, TS Moly, still sells some of the former Guard Dog products, including GD-525 Moly Grease. See: https://www.tsmoly.com/grease-c-2.html

They also now sell their Gear Oil additive in quarts, gallons, 5 gallon pails, and 55 gallon drums. See: https://www.tsmoly.com/additives-c-23.html

By the way, I had/have no interest in Guard Dog or TS Moly, except for an appreciation for a person/company that jumped in to provide a good product for BMW motorcycle owners once they heard about the need.

Last edited:

OGOBRacing

New member

Curious what dealership service departments use?

pglaves

#13338

Curious what dealership service departments use?

They probably use what BMW says to use. This has been a disaster in the past, but Oh Well.

BMW has over the years specified a number of substances for clutch hub spline lubrication. They have included copper based anti-seize which was totally unsuitable. Then they said to use a red grease which was actually Texaco Starplex. It was even more unsuitable than anti-seize. The BMW branded grease would actually melt and ooze sitting on a shelf, let alone in the hot environment inside a bell housing. Then they said use Stabarugs paste which was an assembly lube. One thing about assembly lubes is that they are very good for a short time, which is their purpose. So once again we saw premature spline wear and failures.

I neither know nor care what BMW says to use currently. Normally I am a purist as far as BMW specifications go but not in the case of spline lube. There was a reason that back in the '80s BMW said to lubricate clutch splines once a year and that reason was the use of an unsuitable lubricant. Maybe things are better now. Or maybe not.

weschmann

Kawa Afterthought

They probably use what BMW says to use. This has been a disaster in the past, but Oh Well.

BMW has over the years specified a number of substances for clutch hub spline lubrication. They have included copper based anti-seize which was totally unsuitable. Then they said to use a red grease which was actually Texaco Starplex. It was even more unsuitable than anti-seize. The BMW branded grease would actually melt and ooze sitting on a shelf, let alone in the hot environment inside a bell housing. Then they said use Stabarugs paste which was an assembly lube. One thing about assembly lubes is that they are very good for a short time, which is their purpose. So once again we saw premature spline wear and failures.

I neither know nor care what BMW says to use currently. Normally I am a purist as far as BMW specifications go but not in the case of spline lube. There was a reason that back in the '80s BMW said to lubricate clutch splines once a year and that reason was the use of an unsuitable lubricant. Maybe things are better now. Or maybe not.

So I ordered a Quart can of their TS-90 Moly Gear Concentrate and ask if this a direct application or something that needs to be mixed with another grease to make the final application sufficient? I've never greased a final drive spline before so this is new to me. I am riding a R nineT which I intend to make a permanent bike for my riding foreseeable future so want to make sure I do preventative maintenance.

pglaves

#13338

So I ordered a Quart can of their TS-90 Moly Gear Concentrate and ask if this a direct application or something that needs to be mixed with another grease to make the final application sufficient? I've never greased a final drive spline before so this is new to me. I am riding a R nineT which I intend to make a permanent bike for my riding foreseeable future so want to make sure I do preventative maintenance.

For splines the GD-525 grease is what should be used.

The TS-90 gear oil additive is intended to be used as a 10% additive to transmissions anad final drives.

globalrider

Alps Adventurer

Sine we also talked about gear oil additives...

Dow Corning M Gear Oil Additive was recommended by Oak some 30 years ago.

I've always used it at 5% on all of my single-sided final drives (R100GS, R1150GS) and they have been trouble-free since the early 90s with zilch on the drain plug between changes.

Dow Corning M Gear Oil Additive was recommended by Oak some 30 years ago.

I've always used it at 5% on all of my single-sided final drives (R100GS, R1150GS) and they have been trouble-free since the early 90s with zilch on the drain plug between changes.

Attachments

pglaves

#13338

Sine we also talked about gear oil additives...

Dow Corning M Gear Oil Additive was recommended by Oak some 30 years ago.

I've always used it at 5% on all of my single-sided final drives (R100GS, R1150GS) and they have been trouble-free since the early 90s with zilch on the drain plug between changes.

I started using Gear Guard after advice from Oak in 1982 or '83. Back then it was easy to go get in lots of bearing supply places. After a while it became hard to find - before everything on earth was available on-line. At that time there was not much of a line to be on.

That was the situation when I discovered TS Moly and their line of moly gear oil additives. Gear Guard from Dow Corning remains a good option too.

globalrider

Alps Adventurer

After a while it became hard to find...

I got my quart bottle at my local bearing shop.

So little of it is needed and it is expensive. These products usually have a life of about 3 years so I suggest owners split it with other riders in the area. One bottle makes a mixture of 20 quarts.

pglaves

#13338

I got my quart bottle at my local bearing shop.

I only wish I had a local bearing shop.

globalrider

Alps Adventurer

pglaves

#13338

I just got this from T.S. Moly-Lubricants because I wanted to know if the TS-90 Moly Gear Concentrate could be added to either mineral or synthetic gear oil.

Yes it can. I have done both.

lkraus

New member

Being bored-in-place, I cannot find any current reference to Optimoly TA anywhere except in BMW manuals and some forums.

Castrol did have a product called Optimol TA, that was renamed to Molub-Alloy Paste TA in 2015. Searching for the MSDS, I keep getting messages that the product is not available in my country. Google does find some retailers, but I have not tried to find their locations. Castrol lists some Molub-Alloy products, but not TA.

Then I used the Opera browser VPN to shift my "location" to Europe, which produced some results.

I found it interesting that neither the Castrol product description nor the MSDS sheet show molybdenum as an ingredient, though it does contain graphite.

I plan to continue using Loctite 51048 for my splines.

Castrol did have a product called Optimol TA, that was renamed to Molub-Alloy Paste TA in 2015. Searching for the MSDS, I keep getting messages that the product is not available in my country. Google does find some retailers, but I have not tried to find their locations. Castrol lists some Molub-Alloy products, but not TA.

Then I used the Opera browser VPN to shift my "location" to Europe, which produced some results.

I found it interesting that neither the Castrol product description nor the MSDS sheet show molybdenum as an ingredient, though it does contain graphite.

I plan to continue using Loctite 51048 for my splines.