1074

Active member

Playing the guessing game

I can't believe the variety of guessing games being played here. The fact that there is a clanking noise tells me that you are going to have to take it apart sooner or later!

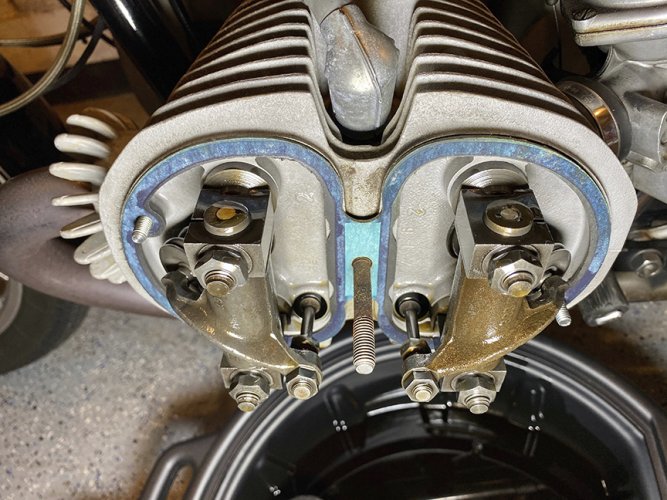

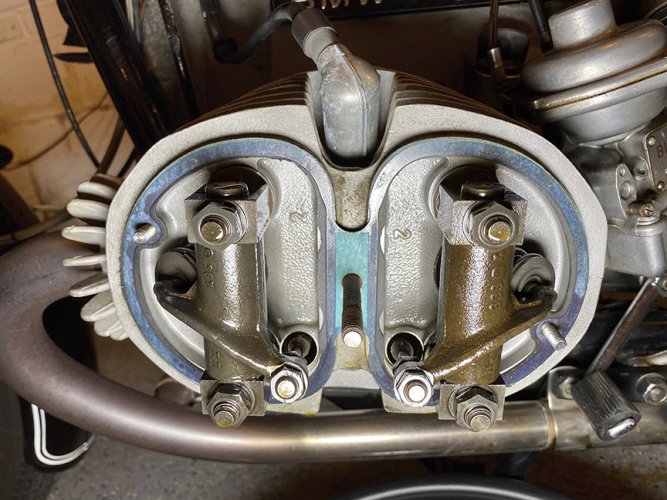

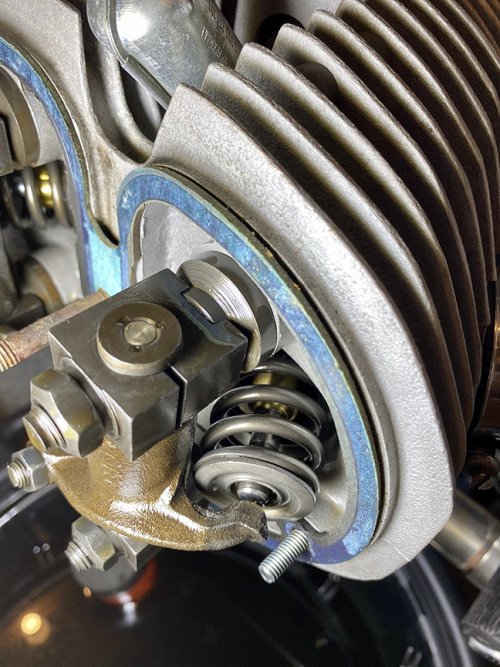

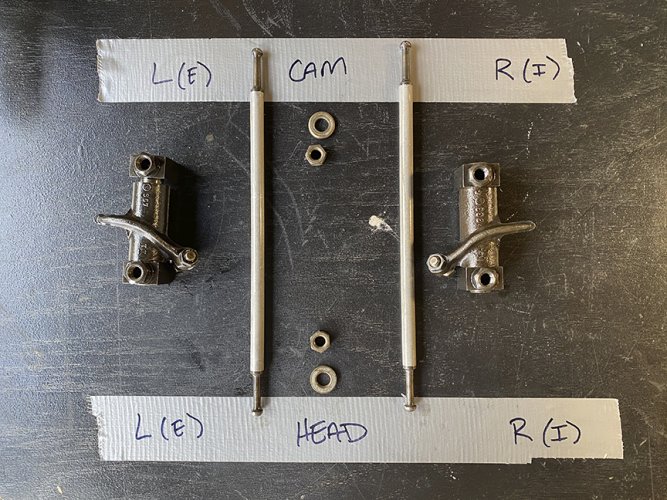

So an inquisitive diagnostic mind would say that with the valve cover off and the rocker arms removed, you might probably find a stuck valve.

But then again, even if that is what is wrong, you're going to end up pulling the whole top end anyway. So taking it all apart makes total sense. Be sure and remove the lifters as well. So then you have the whole picture and can figure it out from there.

I can't believe the variety of guessing games being played here. The fact that there is a clanking noise tells me that you are going to have to take it apart sooner or later!

So an inquisitive diagnostic mind would say that with the valve cover off and the rocker arms removed, you might probably find a stuck valve.

But then again, even if that is what is wrong, you're going to end up pulling the whole top end anyway. So taking it all apart makes total sense. Be sure and remove the lifters as well. So then you have the whole picture and can figure it out from there.