greenmachine1100

New member

Don't know enough about ignition/combustion to understand why this happens only at certain rpms.

Events preceding the problem: essentially ran moto out of gas! Lost, no gas station on GPS, wandered with low fuel light on for about 20miles. Found a gas station by accident/luck. tank had .2 gallons in it. So small and boondocks, only sold one grade of fuel 87 (is it possible it was 85? because that is the number I remember, but not sure it exists). Should have just splashed a gallon in and gone back to civilization, but filled it all up. Noticed a little roughness, but finished the day for about 200 more miles. Bike sat for a day.

On way back from Nevada, through some mountains, bike started misfiring while climbing hills, smooth on downside. After a hundred more miles, and fresh gas the symptoms are this: Only in 5th gear, only at steady speed, between 4000 and 4500. If I climb above 4500, it smooths out and runs normal. Different speeds on different roads coming back to Arizona. Used 4th gear a lot, kept it steady at 3500, 4000, 4500, no misfire or hiccup. Got home, sat for a day, took it out again and same symptoms.

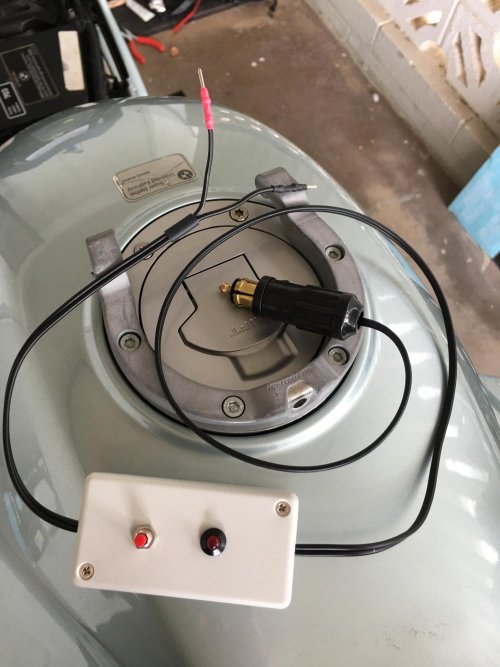

My first idea was to remove tank and see if anything is remiss. Fuel filter was just replaced like 1000 miles ago. It does feel like a fuel delivery problem. If the filter is clogged or a piece of debris is in line- why would it clear up at higher rpm? Once I put a high demand on it, wouldn't fuel delivery just keep falling behind the higher rpm I go? Also, why exactly that rpm? It is running normal in all other gears, at all other rpm. (redline is 7400) Why is 4th gear 4000 different from 5th gear 4000?

Events preceding the problem: essentially ran moto out of gas! Lost, no gas station on GPS, wandered with low fuel light on for about 20miles. Found a gas station by accident/luck. tank had .2 gallons in it. So small and boondocks, only sold one grade of fuel 87 (is it possible it was 85? because that is the number I remember, but not sure it exists). Should have just splashed a gallon in and gone back to civilization, but filled it all up. Noticed a little roughness, but finished the day for about 200 more miles. Bike sat for a day.

On way back from Nevada, through some mountains, bike started misfiring while climbing hills, smooth on downside. After a hundred more miles, and fresh gas the symptoms are this: Only in 5th gear, only at steady speed, between 4000 and 4500. If I climb above 4500, it smooths out and runs normal. Different speeds on different roads coming back to Arizona. Used 4th gear a lot, kept it steady at 3500, 4000, 4500, no misfire or hiccup. Got home, sat for a day, took it out again and same symptoms.

My first idea was to remove tank and see if anything is remiss. Fuel filter was just replaced like 1000 miles ago. It does feel like a fuel delivery problem. If the filter is clogged or a piece of debris is in line- why would it clear up at higher rpm? Once I put a high demand on it, wouldn't fuel delivery just keep falling behind the higher rpm I go? Also, why exactly that rpm? It is running normal in all other gears, at all other rpm. (redline is 7400) Why is 4th gear 4000 different from 5th gear 4000?