pauls1150

MOA #24991, south of Los Angeles

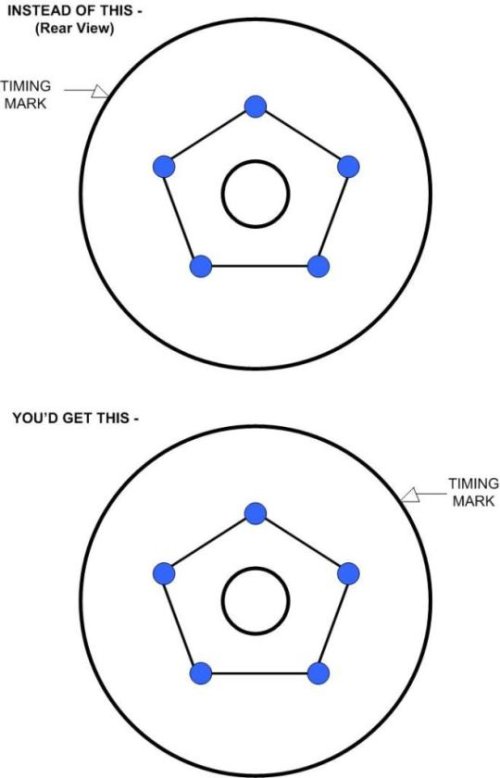

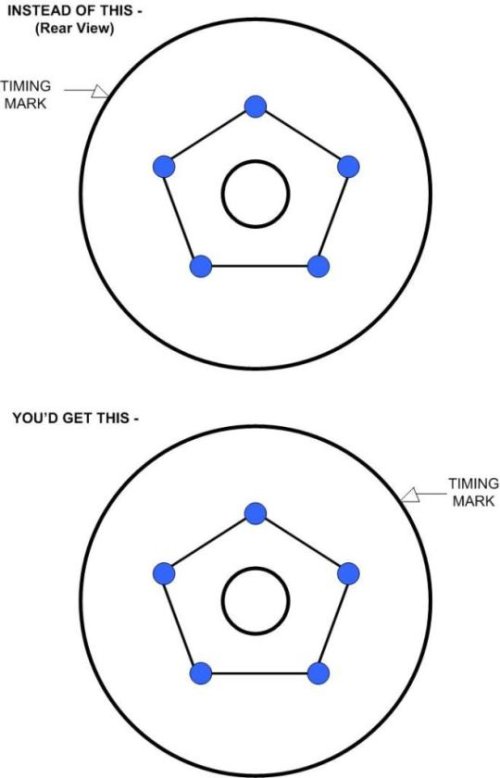

In the November ON, Matt talks about a strange alignment (or lack thereof...) of the timing mark on a '92 R100GS.

QUESTION: It's been a long time since I've been inside an airhead, so - Is it possible that the factory (or somebody) installed that flywheel "backwards", that is, with the wrong "face" forward? (And then it would be impossible to align its timing marks to TDC.)

And as long as I'm displaying my ignorance... Wes's sketch on page 40 does Not show a "flathead" screw top: that's a "Straight Slot" head. The only way to see that a screw is a flathead would be by rotating the view 90 degrees in any direction.

QUESTION: It's been a long time since I've been inside an airhead, so - Is it possible that the factory (or somebody) installed that flywheel "backwards", that is, with the wrong "face" forward? (And then it would be impossible to align its timing marks to TDC.)

And as long as I'm displaying my ignorance... Wes's sketch on page 40 does Not show a "flathead" screw top: that's a "Straight Slot" head. The only way to see that a screw is a flathead would be by rotating the view 90 degrees in any direction.