On my R1100RT, the plastic fuel line from the distribution box to the left side fuel injector had a kink in it. I cut the line and temporally replaced a short section with a rubber fuel injection hose. It has worked for most of the summer but it is time to repair it. Any ideas on how to repair the plastic hose, other than replace the entire distribution box with a new or used one? New ones show on the parts fiche for $140, assuming they are still available.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1996 R1100RT Fuel Distribution Line Repair

- Thread starter oldcarman

- Start date

gsaddict

Pepperfool

I have succesfully spliced them with 5/16" fuel injection hose and proper fuel injection clamps.

You will also need 2 pieces of 1/4" od x 1/2" long copper or SS tubing to push down each end of the pipe.

They are needed to support the pipe when clamp pressure is applied.

Check clamp tightness after 1 day and then again a week later.

BTW the picture above shows a gear type clamp. These are not recommended to be used on fuel injection systems. It should be replaced with the correct FI clamp

You will also need 2 pieces of 1/4" od x 1/2" long copper or SS tubing to push down each end of the pipe.

They are needed to support the pipe when clamp pressure is applied.

Check clamp tightness after 1 day and then again a week later.

BTW the picture above shows a gear type clamp. These are not recommended to be used on fuel injection systems. It should be replaced with the correct FI clamp

I have succesfully spliced them with 5/16" fuel injection hose and proper fuel injection clamps.

You will also need 2 pieces of 1/4" od x 1/2" long copper or SS tubing to push down each end of the pipe.

They are needed to support the pipe when clamp pressure is applied.

Check clamp tightness after 1 day and then again a week later.

BTW the picture above shows a gear type clamp. These are not recommended to be used on fuel injection systems. It should be replaced with the correct FI clamp

Thanks for the question and the answer.

Mine have not broken as of yet, but it's only a mater of time until the do.

The last time I had the tank off I looked at the fuel delivery system and thought to myself, "Be very careful". GSAddict, Thanks for the replacement tip.

1996 R1100RT Fuel Distribution Line Repair plus fuel line shut off valves

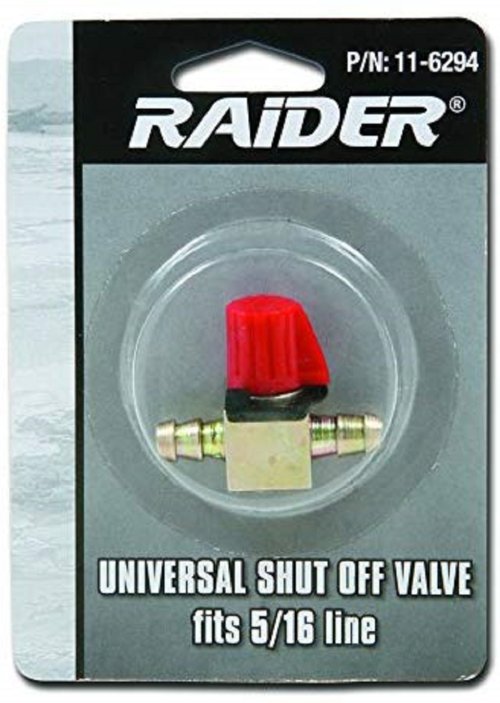

Thanks for the repair tip. Looks like a good idea, especially since I didn't want to go through the work of replacing the distribution box. I have been looking at the quick disconnects you mentioned, but in place of the disconnects I have also been looking at installing a brass 5/16" fuel line shut off valve. I found these on line at one of the motorcycle parts suppliers. I read lot of the comments people posted and they were all good. Amazon has them for $10 with one day delivery. I'm going to install one shut off valve in each of the right side fuel lines, along with the correct hose clamps. This will allow me to turn the valve off and connect a drain line when I want to drain the tank, prior to removal. Hopefully it will work.

Thanks for the repair tip. Looks like a good idea, especially since I didn't want to go through the work of replacing the distribution box. I have been looking at the quick disconnects you mentioned, but in place of the disconnects I have also been looking at installing a brass 5/16" fuel line shut off valve. I found these on line at one of the motorcycle parts suppliers. I read lot of the comments people posted and they were all good. Amazon has them for $10 with one day delivery. I'm going to install one shut off valve in each of the right side fuel lines, along with the correct hose clamps. This will allow me to turn the valve off and connect a drain line when I want to drain the tank, prior to removal. Hopefully it will work.

Attachments

I have been looking at the quick disconnects you mentioned, but in place of the disconnects I have also been looking at installing a brass 5/16" fuel line shut off valve. I'm going to install one shut off valve in each of the right side fuel lines, along with the correct hose clamps. This will allow me to turn the valve off and connect a drain line when I want to drain the tank, prior to removal. Hopefully it will work.

I'm sure it will work however you'll still be faced with yanking off a fuel line on each line with attendant damage inside the hose, would you not?

gsaddict

Pepperfool

I'm sure it will work however you'll still be faced with yanking off a fuel line on each line with attendant damage inside the hose, would you not?

Exactly, the whole idea is not to stress the near 20 year old spider any more than its needs to be,

The barbs exacerbate the problem.

1996 R1100RT Fuel Distribution Line Repair plus fuel line shut off valves

Here is an update on this shut off valve. As the manufacturer says it does fit a 5/16" fuel line but.... internally it will limit flow because the internal diameter is a little less than 3/16". The internal diameter of the 5/16 fuel line is about 1/4". So, I wouldn't use it on the fuel supply side but it may be ok on the fuel return side. As many have recommended, I will now use a quick disconnect coupler or just reconnect the lines as they were. On the couplers, I see CPC offers couplers made from either stainless or plastic. I assume they would both work fine, with the stainless being tougher. Does anyone have any measurements on the physical size of each of these, ie. length and diameter. Thanks, oldcarman

Here is an update on this shut off valve. As the manufacturer says it does fit a 5/16" fuel line but.... internally it will limit flow because the internal diameter is a little less than 3/16". The internal diameter of the 5/16 fuel line is about 1/4". So, I wouldn't use it on the fuel supply side but it may be ok on the fuel return side. As many have recommended, I will now use a quick disconnect coupler or just reconnect the lines as they were. On the couplers, I see CPC offers couplers made from either stainless or plastic. I assume they would both work fine, with the stainless being tougher. Does anyone have any measurements on the physical size of each of these, ie. length and diameter. Thanks, oldcarman

....On the couplers, I see CPC offers couplers made from either stainless or plastic. I assume they would both work fine, with the stainless being tougher. Does anyone have any measurements on the physical size of each of these, ie. length and diameter.

With respect, why try to reinvent the wheel? Beemer Boneyard has what you need, has a proven track record and even gives MOA members a discount.

The advice you're getting in this thread is from some of the most experienced mechanics/engineers you'll ever meet (myself excluded).

Last edited:

52184

GTRider

On the couplers, I see CPC offers couplers made from either stainless or plastic. I assume they would both work fine, with the stainless being tougher. Does anyone have any measurements on the physical size of each of these, ie. length and diameter. Thanks, oldcarman

Buy the QDs from Beemer Boneyard, install them the return line and feed line. Take an old BMW QD and instill it on a 2ft length of spare hose. Now when you need to remove the tank you can disconnect the QDs, install your 2ft drain hose into the tank side fitting of the return line, and drain the tank. And if you don’t have an old set of BMW fittings you can buy the single end you need from Colder Products or your BMW dealer. Jerry-rigging extra fittings like a shutoff valve just complicates things and introduces more failure points.

Best,

DeVern

Similar threads

- Replies

- 4

- Views

- 415