Hi,

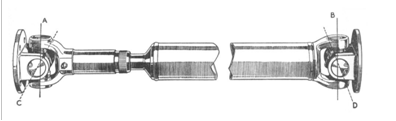

Before I open up the final drive to grease the spline and check wear, are there some tricks to keep the two shafts in proper phase? Phase is a new term to me but I think it means keeping the Universal joints in proper positions to avoid vibration or something bad.

History on my 2003 K1200GT and 27k miles is missing for greasing of the splines. After 16 years, probably a good thing to investigate. Lots of work done at BMW shops but no mention of FD work. Looked like a chance to try out my new 30mm cutout socket.

After tipping down the FD and separating the shorter rear drive shaft from the longer drive shaft, I can then check that spline. But when I remove the short rear drive shaft off the FD to check the rear spine, isn't there a problem with not reconnecting it in the same location. Get it out of phase?

Bike running great, no problems with the FD just preventative medicine.

Thanks for your ideas.

Before I open up the final drive to grease the spline and check wear, are there some tricks to keep the two shafts in proper phase? Phase is a new term to me but I think it means keeping the Universal joints in proper positions to avoid vibration or something bad.

History on my 2003 K1200GT and 27k miles is missing for greasing of the splines. After 16 years, probably a good thing to investigate. Lots of work done at BMW shops but no mention of FD work. Looked like a chance to try out my new 30mm cutout socket.

After tipping down the FD and separating the shorter rear drive shaft from the longer drive shaft, I can then check that spline. But when I remove the short rear drive shaft off the FD to check the rear spine, isn't there a problem with not reconnecting it in the same location. Get it out of phase?

Bike running great, no problems with the FD just preventative medicine.

Thanks for your ideas.