Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Doing top end reseal - o-rings?

- Thread starter ARMYMUTT

- Start date

As critical as this might be, I'd be inclined to use the proper part from the dealer, etal. I notice that the part is also used on some K-bikes:

http://www.realoem.com/bmw/enUS/partxref?q=11+11+1460391

Maybe they're back ordered for all applications? Could you get them from some other source like a dealer, etc.? Benchmark Works shows them available on their site:

http://www.benchmarkworks.com

http://www.realoem.com/bmw/enUS/partxref?q=11+11+1460391

Maybe they're back ordered for all applications? Could you get them from some other source like a dealer, etc.? Benchmark Works shows them available on their site:

http://www.benchmarkworks.com

beemerphile

New member

I was hoping to be able to get them from the local BMW car dealer rather than having to drive an hour to get them or pay three times the price of the o-rings for shipping. Here's one for a Porsche: https://www.autohausaz.com/pn/VZ-99970113550

lmo1131

New member

I'd be surprised if your local BMW car dealer would be able to get them; worth a try I reckon...

I'd just order them from any of the "on line" dealers, i.e. MAXBMW, Bob's, etc.

$7.00 shipping from Euromotoelectric.. .. I think you'd be hard pressed to spend less collecting them locally.

I'd just order them from any of the "on line" dealers, i.e. MAXBMW, Bob's, etc.

$7.00 shipping from Euromotoelectric.. .. I think you'd be hard pressed to spend less collecting them locally.

happy wanderer

Day Dreaming ...

Motobins has them as well.

I ended up going with a different vendor, but they shorted me 1 wristpin circlip. I emailed Capital Cycle, but haven't received a reply and haven't been able to call them. How critical is it to replace them? I suppose I can do one side to start with and maybe they will have the 4th one to me next week.

Any hints or tricks for this job? I've never taken the jugs off any engine before. Well, there was a lawnmower in HS back in '91, but I don't remember much about it now.

Any hints or tricks for this job? I've never taken the jugs off any engine before. Well, there was a lawnmower in HS back in '91, but I don't remember much about it now.

terham

BeemerBoy

For top end work, I always refer to Oak Oakleshen's manual, which I think is still available from various sources.

You could also take a look at Brook's website, which I find very helpful. Just reverse these steps.

https://brook.reams.me/bmw-motorcycle-rebuilds/1973-bmw-r755-rebuild-project/11-bmw-r755-install-engine-top-end/

You could also take a look at Brook's website, which I find very helpful. Just reverse these steps.

https://brook.reams.me/bmw-motorcycle-rebuilds/1973-bmw-r755-rebuild-project/11-bmw-r755-install-engine-top-end/

I'd make sure I had new ones for this critical purpose. The old ones will get distorted or surfaces won't be as sharp as when new.

The clips will be of two types. My R69S had internal clips that fit in a groove inside the piston. They were a bugger for me to get out...I think I was able to rotate wire clip around so I could grab the end with a pair of needle nose pliers and then bend/lever it out of the groove. To reinstall, I used my fingers to get the clip started in the hole and then a perfect sized socket to tap the clip home. The other type is external and you'll need a set of snap ring pliers. This type of clip is easy to take off and put on. I believe there is a proper orientation to this clip...one side is supposed to be facing out.

You might need to heat the piston where the wrist pins pass through...a hair dryer or paint stripping gun on low setting should be enough to let the wrist pins be pushed out by thumbs. Don't put too much side force on the connecting rod. And be sure and catch the connecting rod to keep it from falling when you pull the jugs off. You don't want to let the sharp edge of the rod fall down and hit the opening of the engine case.

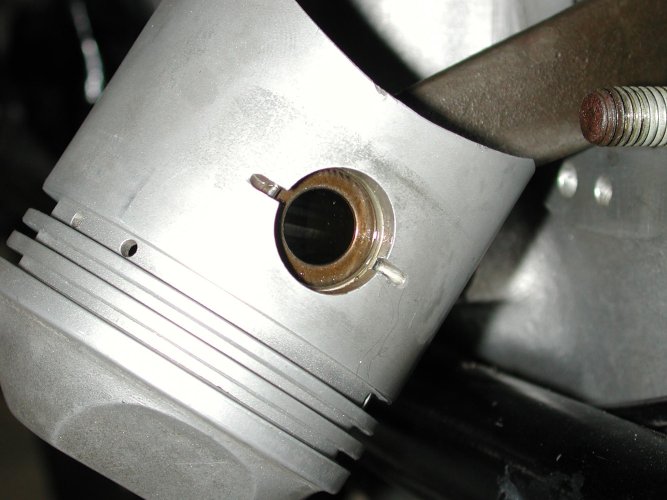

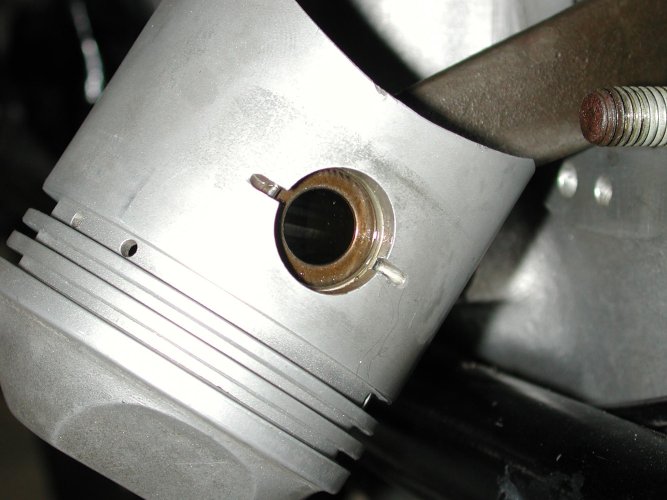

First picture is of the internal clip; the second shows the external clips and the groove on the wrist pin where they fit.

The clips will be of two types. My R69S had internal clips that fit in a groove inside the piston. They were a bugger for me to get out...I think I was able to rotate wire clip around so I could grab the end with a pair of needle nose pliers and then bend/lever it out of the groove. To reinstall, I used my fingers to get the clip started in the hole and then a perfect sized socket to tap the clip home. The other type is external and you'll need a set of snap ring pliers. This type of clip is easy to take off and put on. I believe there is a proper orientation to this clip...one side is supposed to be facing out.

You might need to heat the piston where the wrist pins pass through...a hair dryer or paint stripping gun on low setting should be enough to let the wrist pins be pushed out by thumbs. Don't put too much side force on the connecting rod. And be sure and catch the connecting rod to keep it from falling when you pull the jugs off. You don't want to let the sharp edge of the rod fall down and hit the opening of the engine case.

First picture is of the internal clip; the second shows the external clips and the groove on the wrist pin where they fit.

Oak's manual can be bought from his estate. Information is in the link in my signature line.

The decision to replace rings typically results from measuring compression and/or leak down as well as measuring the ring end gap. The gap is easy enough to do...put the ring into the bore and use the piston to square it up. Then find the feeler gage to slip between the ends of the ring. There are specs for the end gap. Also, measuring the shape of the cylinder at say three locations...near the top, mid bore, and near the bottom. That lets you know how close to spec the cylinder walls. You didn't say how many miles or other things about performance...oil usage etc.

Something that wasn't mentioned is the idea of leaving the piston w/ rings inside the cylinder when the wrist pin in removed. You would slide the cylinder up until the wrist pin is barely exposed...then remove the pin. If the circlip is internal, I think it's pretty hard to do all that with the limited amount of the cylinder that is exposed. But if you do it this way, you wouldn't disturb where the rings are and how they are running.

The decision to replace rings typically results from measuring compression and/or leak down as well as measuring the ring end gap. The gap is easy enough to do...put the ring into the bore and use the piston to square it up. Then find the feeler gage to slip between the ends of the ring. There are specs for the end gap. Also, measuring the shape of the cylinder at say three locations...near the top, mid bore, and near the bottom. That lets you know how close to spec the cylinder walls. You didn't say how many miles or other things about performance...oil usage etc.

Something that wasn't mentioned is the idea of leaving the piston w/ rings inside the cylinder when the wrist pin in removed. You would slide the cylinder up until the wrist pin is barely exposed...then remove the pin. If the circlip is internal, I think it's pretty hard to do all that with the limited amount of the cylinder that is exposed. But if you do it this way, you wouldn't disturb where the rings are and how they are running.

That's not a bad idea, leaving the pistons in place. The bike has about 47K on it. Not using oil that I can tell, at least not significantly. There's a little smoke on start up, but that goes away after riding. I did find some oil leaking out when I left it on the side stand for a few days after I pulled the sidecar and before installing the center stand. The reason for the reseal is that it is leaking out of a variety of places. Otherwise, the bike runs great - better than my '04 Bonnie right now.

pglaves

#13338

As far as rings are concerned I would never replace them "just because" I was in there. Unless I had an oil consumption issue traced to rings, or low compression, or a failing leakdown test I would not disturb the rings. A new set of rings leads to a new break-in which might not be as sufficient as the original break-in. I personally prefer to leave pistons in the cylinder just disconnecting at the rod. That provides the least disturbance to the piston, ring, cylinder sealing. And it simplifies matters when you don't have a take-apart ring compressor. Poking things into place with a screwdriver always can lead to questionable ressults.

Disassembly is going pretty smooth so far. I'm trying to figure out how to get the circlips out of their groove so I can remove the wrist pins. The Clymer manual says to use a small screwdriver, which is just pushing the clip around in a circle. I've tried to get a dental pick under it without luck.

Yeah, those internal clips are a mutha. You're going to need to grab it and lever it up, that is collapse the circle creating by the clip. Once you do that, then it will be small enough to pull out through the bore. The need to do all this with the cylinder in place requires some finesse. What I would try is to rotate the clip around so the gap is nearly the same as the small slot in the bore of the wrist pin hole. Then either with a very strong pick or a narrow set of needle nose, grab the end of the clip and move it so that it collapses some so it will be able to slip out the hole. From Oak's manual, he says to use a hardened tip awl in the shape of an "L". Get behind the clip, raise the awl up, and pop the clip out.

Good luck!

Good luck!

Yep, a small pick should do it.

I find it entertaining when I hear if people having trouble removing and installing wrist pin clips. I guess I have done it several hundred times, maybe even over a thousand times. So often I don't even think about it. I had someone ask me how to remove and install the clips, and I can't even tell you how I do it! Out, I use a pick, in, I use a small screwdriver, but other than that I couldn't explain how I do it!

I find it entertaining when I hear if people having trouble removing and installing wrist pin clips. I guess I have done it several hundred times, maybe even over a thousand times. So often I don't even think about it. I had someone ask me how to remove and install the clips, and I can't even tell you how I do it! Out, I use a pick, in, I use a small screwdriver, but other than that I couldn't explain how I do it!

No sealant on the head gasket. As for the cylinder base, look at what gunsmoke blogged about. Ted Porter recommends Permatex Ultra Gray.

From my signature line:

https://www.pbase.com/dqmohan/prtseals

http://www.gunsmoke.com/motorcycling/r100gs/pushrod_tubes/index.html

From my signature line:

https://www.pbase.com/dqmohan/prtseals

http://www.gunsmoke.com/motorcycling/r100gs/pushrod_tubes/index.html

I managed to get 3 out of 4 circlips out. Thanks for the tip on the cut out section - didn't see it initially. Since I only have 3 new ones, I'm not sure I want to get the 4th out. I currently have the heads sitting in a box and the cylinders on the lift with pistons in the bores. The bores are smooth and the pistons don't have much carbon on them. Can I safely clean the grease off both parts using brake cleaner or something like that? Where should I look for wear to determine if a part is unserviceable? I'll pick up some sealer tomorrow.

Similar threads

- Replies

- 2

- Views

- 583