Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

99 1100rs valve adj. question

- Thread starter gagnello

- Start date

Remove the spark plugs from each cylinder. It is much easier to rotate the engine if one doesn't have to fight against engine compression. It is often convenient to have the bike on the center stand and then shift into a high gear (5th or 6th). Rotate the rear tire to turn the engine over while keeping a watch for the timing mark on the flywheel (one must remove the rubber inspection plug). A small flashlight can be helpful to see the timing mark in the inspection port.

Following is a link to a manual to service oilheads -

https://ibmwr.org/original/r-tech/oilheads/R11Manual/Oilhead_Maintenance_2-25-02.pdf

Following is a link to a manual to service oilheads -

https://ibmwr.org/original/r-tech/oilheads/R11Manual/Oilhead_Maintenance_2-25-02.pdf

m_stock10506

Well-known member

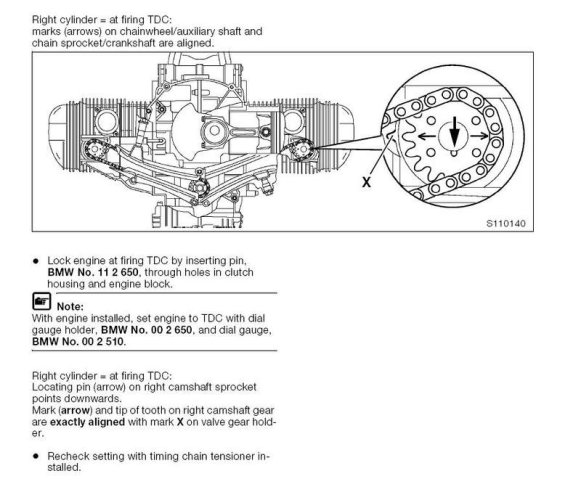

For those that don’t like removing the rubber timing hole cover, there are arrows on the cam chain sprockets. When the arrows are horizontal, then you are at TDC. Check the valves on each side to see which side has play. That is the side you adjust. Rotate the motor to the next arrow and then the other side should have play. Adjust that side. Yes, it is much easier to rotate the motor with the plugs out.

Last edited:

K7GLE

New member

For those that don’t like removing the rubber timing hole cover, there are arrows on the cam chain sprockets. When the arrows are horizontal, then you are at TDC. Check the valves on each side to see which side has play. That is the side you adjust. Rotate the motor to the next arrow and then the other side should have play. Adjust that side. Yes, it is much easier to rotate the motor with the plugs out.

View attachment 72771

+1

happy wanderer

Day Dreaming ...

For those that don’t like removing the rubber timing hole cover, there are arrows on the cam chain sprockets. When the arrows are horizontal, then you are at TDC. Check the valves on each side to see which side has play. That is the side you adjust. Rotate the motor to the next arrow and then the other side should have play. Adjust that side. Yes, it is much easier to rotate the motor with the plugs out.

View attachment 72771

Not to confuse things further but when the notch in the pulley is DOWN like it is in the photo above the RIGHT side is at TDC. When the notch in the pulley is pointing UP or opposite to the photo above the LEFT side is at TDC.

Should you ever have to replace a busted timing chain *ask Paul Glaves about how much fun THAT is* this is a very useful thing to know. Or if you are just confused about which side is at TDC down right and up left is easy to remember.

This illustration is the view from the REAR of the motor and you can tell this by the cam chain tensioner which is inserted pointing up. The left side is inserted from the top and points down.

dieselyoda

Active member

Less complicated, equally as effective: valve cover off, plugs removed, tranny in a gear, 5th is great, turn engine over until an arrow, either side is close, try to spin the pushrods. If you can spin the pushrods by finger, adjust those valves. If you can't spin the pushrods, adjust the other side.

Turn engine over and repeat.

You have about 45 degrees from TDC to adjust the valves while the other side is starting or ending overlap.

It's only a two cylinder engine. Try to do 6 cylinders with only two turns of the crankshaft!

Turn engine over and repeat.

You have about 45 degrees from TDC to adjust the valves while the other side is starting or ending overlap.

It's only a two cylinder engine. Try to do 6 cylinders with only two turns of the crankshaft!

m_stock10506

Well-known member

I always just remove the front cover and turn the crankshaft with a socket and wrench this way. It takes less than a minute to remove the cover. Why folks think turning the rear wheel in 4th or 5this easier escapes me.

Wait a minute Paul, while I clean up the coffee that spilled while I was laughing. You are talking about your RS aren't you? Now, remove that front cover on the RT while you remove the side fairings, the bottom piece, and the shark fin in order to twist the front cover and drop it down and out. On the RT, turning the rear wheel in gear is a piece of cake.

pauls1150

MOA #24991, south of Los Angeles

I have an Ohlins shock on the front of my RT, and it's pretty darn hard to wiggle the front cover out of there.

One might also punch a hole in the cover, per info from the Internet BMW Riders site - begin quote:

I asked Duncan, of Duncan's Beemers (located in Maynard, Massachusetts), to modify my Oilhead's pulley cover so that a simple plug could be inserted directly over the spot where the 16mm pulley nut (which is used to turn the engine over to find TDC) is located.

Duncan took a new pulley cover (sure, I could have used the one on my bike, but I wasn't sure this was gonna work). He found that the 16mm nut we needed to get to was directly under the BMW embossed logo on the bottom of the black plastic cover. He speculates, and I concur, that someone at BMW once had in mind doing exactly what we did. Duncan removed the logo using a 23mm hole cutter, then cleaned up the remaining excess plastic by hand. He then took a round rubber plug; a /5 fork leg bottom (part #31422000381 – the diameter of that part of the plug which holds it in place is .926" ). The plug fits perfectly in the hole Duncan made. Now, when it comes time to do my valves, I'll only have to pop out this small rubber plug, stick my 16mm socket inside, and go to work.

One might also punch a hole in the cover, per info from the Internet BMW Riders site - begin quote:

I asked Duncan, of Duncan's Beemers (located in Maynard, Massachusetts), to modify my Oilhead's pulley cover so that a simple plug could be inserted directly over the spot where the 16mm pulley nut (which is used to turn the engine over to find TDC) is located.

Duncan took a new pulley cover (sure, I could have used the one on my bike, but I wasn't sure this was gonna work). He found that the 16mm nut we needed to get to was directly under the BMW embossed logo on the bottom of the black plastic cover. He speculates, and I concur, that someone at BMW once had in mind doing exactly what we did. Duncan removed the logo using a 23mm hole cutter, then cleaned up the remaining excess plastic by hand. He then took a round rubber plug; a /5 fork leg bottom (part #31422000381 – the diameter of that part of the plug which holds it in place is .926" ). The plug fits perfectly in the hole Duncan made. Now, when it comes time to do my valves, I'll only have to pop out this small rubber plug, stick my 16mm socket inside, and go to work.

My front cover is cut in half, held in place by two bolts (and the cut is sealed by gaffer tape). It is simply a matter of removing the gaffer tape and the two bolts, putting a socket on the bolt to turn the engine.

In the future Paul, I will try the rotation in first gear to see for myself if there is any difference than in fifth with this approach.

Having said that, I do like Duncan's solution.

It's been awhile but I have on occasion, ridden to Maynard for Duncan's expertise.

In the future Paul, I will try the rotation in first gear to see for myself if there is any difference than in fifth with this approach.

Having said that, I do like Duncan's solution.

It's been awhile but I have on occasion, ridden to Maynard for Duncan's expertise.

gsaddict

Pepperfool

I always just remove the front cover and turn the crankshaft with a socket and wrench this way. It takes less than a minute to remove the cover. Why folks think turning the rear wheel in 4th or 5this easier escapes me.

This is my preferred way as well.

It allows inspection of the polyvee belt condition at the same time.

.

gsaddict

Pepperfool

I have an Ohlins shock on the front of my RT, and it's pretty darn hard to wiggle the front cover out of there.

One might also punch a hole in the cover, per info from the Internet BMW Riders site - begin quote:

I asked Duncan, of Duncan's Beemers (located in Maynard, Massachusetts), to modify my Oilhead's pulley cover so that a simple plug could be inserted directly over the spot where the 16mm pulley nut (which is used to turn the engine over to find TDC) is located.

Duncan took a new pulley cover (sure, I could have used the one on my bike, but I wasn't sure this was gonna work). He found that the 16mm nut we needed to get to was directly under the BMW embossed logo on the bottom of the black plastic cover. He speculates, and I concur, that someone at BMW once had in mind doing exactly what we did. Duncan removed the logo using a 23mm hole cutter, then cleaned up the remaining excess plastic by hand. He then took a round rubber plug; a /5 fork leg bottom (part #31422000381 – the diameter of that part of the plug which holds it in place is .926" ). The plug fits perfectly in the hole Duncan made. Now, when it comes time to do my valves, I'll only have to pop out this small rubber plug, stick my 16mm socket inside, and go to work.

I have Ohlins on my GS and encounter the same issue.

Next time you have the cover off check the inside top of the cover.

There is a plastic reinforcement inside that can be trimmed to allow the cover to slip by the alternator nut.

My R1100RT also has Ohlins shocks, and with the front cover cut horizontally in half, it is not difficult to remove that cover. Having said that, I would still prefer to have what Duncan did to your front cover.I have an Ohlins shock on the front of my RT, and it's pretty darn hard to wiggle the front cover out of there.[/COLOR]

Cheers!

(another) Paul

happy wanderer

Day Dreaming ...

Get yourself a CB750 valve cover cap from a junk yard. Drill out with a small hole saw or large drill bit and use a curved file to round out the hole leaving enough plastic to thread the cap into. When you are done, remove the plug and insert 15mm socket and move the engine easily (with the plugs out that is)

pglaves

#13338

Wait a minute Paul, while I clean up the coffee that spilled while I was laughing. You are talking about your RS aren't you? Now, remove that front cover on the RT while you remove the side fairings, the bottom piece, and the shark fin in order to twist the front cover and drop it down and out. On the RT, turning the rear wheel in gear is a piece of cake.

Yes: an R1100RS and an R1150R. I eschew those plastic covered behemouths that multiply maintenance efforts by a full order of magnitude. I also did some handy work on an R1100GS where the engine guards posed problems. On that one we just cut the front cover into two pieces and just removed half to access the front pulley on the driveshaft. I do sympathize with the RT guys and gals. Just exactly how to watch the flywheel timing hole while turning the rear wheel was way above my pay grade.

... Just exactly how to watch the flywheel timing hole while turning the rear wheel was way above my pay grade....

Bike on centerstand. You - seated on stool on left side of bike. Rubber timing plug removed, bike in 5th gear. Small flashlight held in mouth. Use right foot to nudge rear wheel whilst watching flywheel turn. When TDC timing mark appears, stop turning rear wheel. What could be easier ?

Bike on centerstand. You - seated on stool on left side of bike. Rubber timing plug removed, bike in 5th gear. Small flashlight held in mouth. Use right foot to nudge rear wheel whilst watching flywheel turn. When TDC timing mark appears, stop turning rear wheel. What could be easier ?

Juggling running chainsaws?

gsaddict

Pepperfool

The other rightIsn't the rubber plug on the right side?

Similar threads

- Replies

- 21

- Views

- 624

- Replies

- 14

- Views

- 790

- Replies

- 5

- Views

- 425