lee

Debbie's Servant

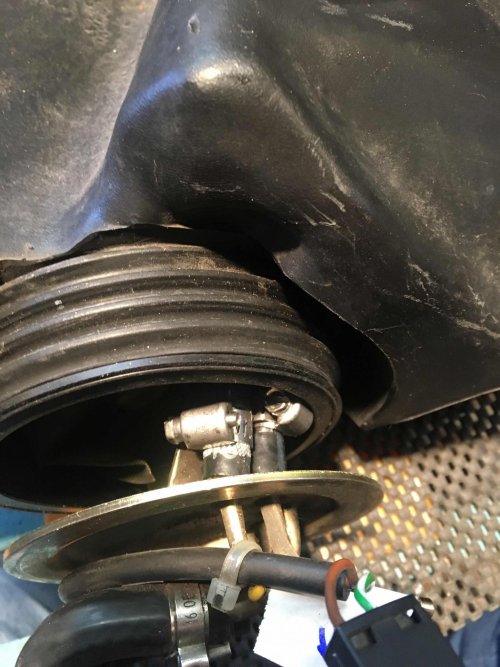

Any suggestions on the dead fly in the air intake?

I don't know if it's a problem.

Sometimes it's better to pretend it never happened

Between my K1200RS and my wife's K1200RS I changed quite a few air filters, and I'm guessing one or two bugs dropped down into the airbox when changing those filters.