I have researched this issue several years ago. I am hoping new alternatives are now available.

Worn Brake Drum, diameter measured a years back and found worn past Specs, a few thousandths over. The drum is an integral part of the wheel. Currently have almost no rear brakes. I have replaced shoes with new OEM and some non. Works marginally for a short time only.

Solutions found then:

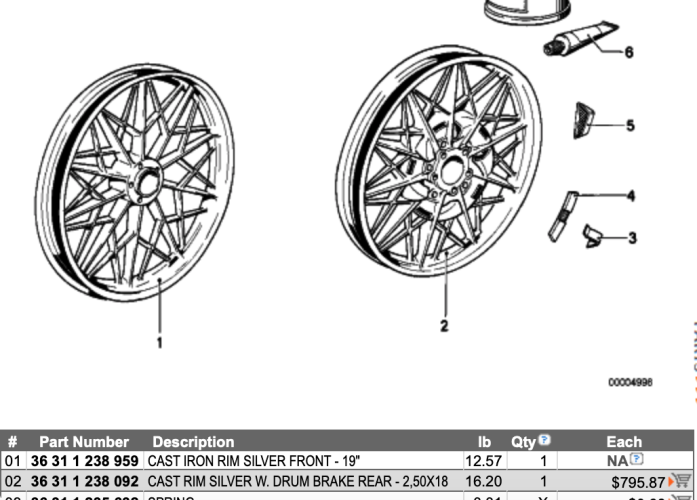

New rear Snowflake wheel. Unknown availability and big bucks !, Used wheels available but it would be taking chances on drum and splines.

Oversize brake shoes: Unknown availability, and or specifications.

Has anyone successfully resolved this problem? Ideas requested.

Rod

Worn Brake Drum, diameter measured a years back and found worn past Specs, a few thousandths over. The drum is an integral part of the wheel. Currently have almost no rear brakes. I have replaced shoes with new OEM and some non. Works marginally for a short time only.

Solutions found then:

New rear Snowflake wheel. Unknown availability and big bucks !, Used wheels available but it would be taking chances on drum and splines.

Oversize brake shoes: Unknown availability, and or specifications.

Has anyone successfully resolved this problem? Ideas requested.

Rod