glenfiddich

TravelsWithBarley.com

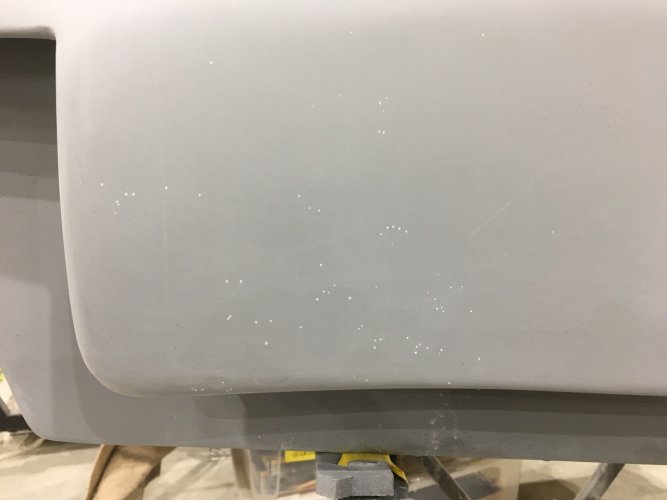

A huge step forward today! All the fiberglass and plastic parts got a double coat of epoxy sealer. Paint often looks slightly different when sprayed over dissimilar surfaces. The epoxy prime seals all those pieces parts no matter what their composition, providing a uniform base for the next coating. Next comes a LOT of wet sanding with 400 grit, then two layers of high build primer, more sanding, and finally the finish coat.

As is always the case with painting, prep work is 90% of the job. Each piece was arranged on a platform. Those that needed to be raised off the platform so all paintable surfaces could be reached required on-the-spot jigs made out of scrap lumber. Then each piece was wiped down with pre-cleaner, then a tack cloth to ensure all contaminants were removed. The cockpit and trunk of the tub were carefully masked off

And then the spraying began. I'm not an experienced painter and this was by far my biggest project attempted. There were a few runs, especially in the recess of the air scoop which proved particularly difficult to maneuver the spray gun near, but overall I was very happy with the results. I missed a few spots on the first coat, but got them on the second. And sure enough there were several pinholes that I'd missed during the sanding process that taunted me with a vindictive "Neener, neener, neener!" I'll have to go back with polyester glaze during the next sanding phase.

When I was done, and the paint booth was on the bake cycle, I stood outside the booth and noticed the perfect symmetry of the frontal view. It stopped me in my tracks! After all that work eliminating the recessed headlight and trim piece, the reflection off that work of art was simply stunning!

As is always the case with painting, prep work is 90% of the job. Each piece was arranged on a platform. Those that needed to be raised off the platform so all paintable surfaces could be reached required on-the-spot jigs made out of scrap lumber. Then each piece was wiped down with pre-cleaner, then a tack cloth to ensure all contaminants were removed. The cockpit and trunk of the tub were carefully masked off

And then the spraying began. I'm not an experienced painter and this was by far my biggest project attempted. There were a few runs, especially in the recess of the air scoop which proved particularly difficult to maneuver the spray gun near, but overall I was very happy with the results. I missed a few spots on the first coat, but got them on the second. And sure enough there were several pinholes that I'd missed during the sanding process that taunted me with a vindictive "Neener, neener, neener!" I'll have to go back with polyester glaze during the next sanding phase.

When I was done, and the paint booth was on the bake cycle, I stood outside the booth and noticed the perfect symmetry of the frontal view. It stopped me in my tracks! After all that work eliminating the recessed headlight and trim piece, the reflection off that work of art was simply stunning!

Last edited: