Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cam Seal Replacement with engine in frame / R60/6

- Thread starter kentuvman

- Start date

-

- Tags

- cam seal replacement

pglaves

#13338

Hi everyone- I have a leaking front cam seal that's dripping oil onto the points - also read Brooke Reams thread on replacing a leaking camshaft seal behind points / timing plate

In his pictorial, engine is removed from frame.

Can this be done with engine in frame?

Thank You

Yes

kentuvman

New member

Thank You, Paul - ordered this seal removal tool and read using a heat gun will help removal.

Attachments

kentuvman

New member

I did the one one on my /7 that way. If the seal puller doesn't work, you can carefully drill a small pilot hole and then drive a small screw into the body of the seal. Then pull the seal out with a pair of pliers. Mine came out pretty easily.

Thanks guys - what an experience it was - rode 40 miles to an Airhead tech day and when we went to balance the carbs I'd overhauled, the bike wouldn't fire - turns out oil on the points from the leaky seal . . .

Love project in progress!

I did one on a r75, long before the info-net. I guess ignorance is bliss. I just carefully picked it out with a small screwdriver or something similar, didn't use heat and it was all done in a matter of a few minutes. With that seal puller and some heat, you should be down town julie brown. good luck. Chunk.

kentuvman

New member

I don't have much experience with setting points but understand setting timing as I have an '82 Airhead with the bean can ignition system.

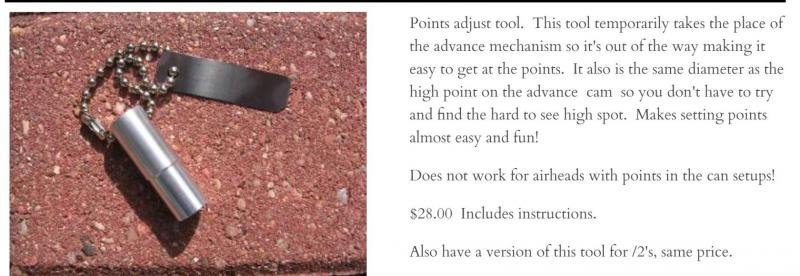

Before I remove points & timing plate to get to the seal, I'll want to scribe or paint a mark to reference the current position of the timing plate - I've also got the point setting tool (see pic) from Northwoods Airheads but have never used it.

Do you suggest I align the "S" on the flywheel in the window before I start the job?

Any tips appreciated so I can put bike together again and have it set to the current timing so bike will start and I can fine tune later.

Thank You

Before I remove points & timing plate to get to the seal, I'll want to scribe or paint a mark to reference the current position of the timing plate - I've also got the point setting tool (see pic) from Northwoods Airheads but have never used it.

Do you suggest I align the "S" on the flywheel in the window before I start the job?

Any tips appreciated so I can put bike together again and have it set to the current timing so bike will start and I can fine tune later.

Thank You

Attachments

I've never owned this tool, but the way I understand it, you remove the advance unit leaving just the points and rubbing block. The rubbing block rides on the eccentric part of the advance unit...it has high and low spots. With this tool, you don't need to worry about where to turn the engine to find the high spot, or find the S-mark, etc. The tool creates a "high" spot at any position. You just set the points, pull the tool, then reinsert the advance unit.

This all works well if...if...everything is to spec. The approach is to set the gap to the nominal 0.016" (from memory) and then begin to set the timing so the points open at the S-mark. If the timing is advance or retarded, then the process is to rotate the points plate to get the proper timing. But what if you rotate the points plate but can't rotate it far enough to get the proper timing? The botch job approach is to open up the slots in the points plate. You can bet the factory would never have done that!

The way around this situation is to change the points gap to something other than the nominal. A small change in points gap makes a big change in the time of points opening. The gap can be a wide range, something like 0.012 to 0.022 and the bike will run fine. The only time the gap is critical is on many multi cylinder engines like 6- or 8-cylinders. The gap...or in reality the amount of time the points are closed...defines the amount of time the current is flowing to the coils to saturate them before the points open. When they open, the field collapses and the spark is generated at the plug. So, don't be afraid of changing the gap to something other than nominal if the situation calls for it.

This all works well if...if...everything is to spec. The approach is to set the gap to the nominal 0.016" (from memory) and then begin to set the timing so the points open at the S-mark. If the timing is advance or retarded, then the process is to rotate the points plate to get the proper timing. But what if you rotate the points plate but can't rotate it far enough to get the proper timing? The botch job approach is to open up the slots in the points plate. You can bet the factory would never have done that!

The way around this situation is to change the points gap to something other than the nominal. A small change in points gap makes a big change in the time of points opening. The gap can be a wide range, something like 0.012 to 0.022 and the bike will run fine. The only time the gap is critical is on many multi cylinder engines like 6- or 8-cylinders. The gap...or in reality the amount of time the points are closed...defines the amount of time the current is flowing to the coils to saturate them before the points open. When they open, the field collapses and the spark is generated at the plug. So, don't be afraid of changing the gap to something other than nominal if the situation calls for it.

kentuvman

New member

I've never owned this tool, but the way I understand it, you remove the advance unit leaving just the points and rubbing block. The rubbing block rides on the eccentric part of the advance unit...it has high and low spots. With this tool, you don't need to worry about where to turn the engine to find the high spot, or find the S-mark, etc. The tool creates a "high" spot at any position. You just set the points, pull the tool, then reinsert the advance unit.

This all works well if...if...everything is to spec. The approach is to set the gap to the nominal 0.016" (from memory) and then begin to set the timing so the points open at the S-mark. If the timing is advance or retarded, then the process is to rotate the points plate to get the proper timing. But what if you rotate the points plate but can't rotate it far enough to get the proper timing? The botch job approach is to open up the slots in the points plate. You can bet the factory would never have done that!

The way around this situation is to change the points gap to something other than the nominal. A small change in points gap makes a big change in the time of points opening. The gap can be a wide range, something like 0.012 to 0.022 and the bike will run fine. The only time the gap is critical is on many multi cylinder engines like 6- or 8-cylinders. The gap...or in reality the amount of time the points are closed...defines the amount of time the current is flowing to the coils to saturate them before the points open. When they open, the field collapses and the spark is generated at the plug. So, don't be afraid of changing the gap to something other than nominal if the situation calls for it.

Thank You Kurt

Similar threads

- Replies

- 10

- Views

- 407