http://www.cycleworks.net/index.php?main_page=product_info&cPath=29_33_53&products_id=48

Hey All

1978 R-80/7 is the patient here.

The wheels turn fine, no play ;just want to put a little fresh grease in there.

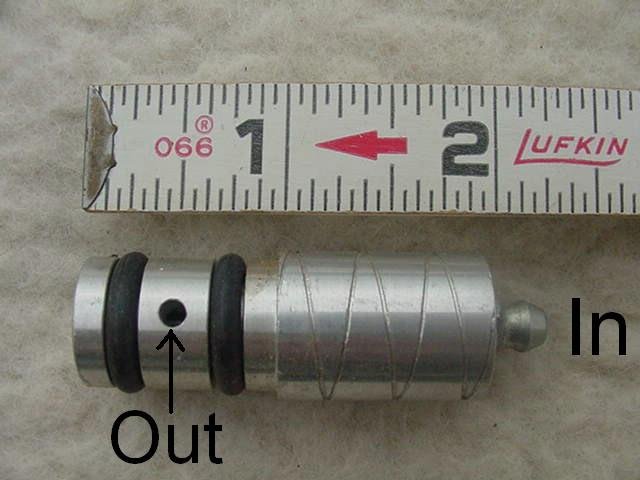

I found this bearing greaser online, does anyone have experience with it?

I just want to put some new grease in my bearings without taking them all apart.

Thumbs up or thumbs down on this product

Thanks in advance

Nick

Hey All

1978 R-80/7 is the patient here.

The wheels turn fine, no play ;just want to put a little fresh grease in there.

I found this bearing greaser online, does anyone have experience with it?

I just want to put some new grease in my bearings without taking them all apart.

Thumbs up or thumbs down on this product

Thanks in advance

Nick