My 1978 R100/7 was not charging the battery. I did some researched and I believe the ignition rotor is bad. When checked for resistance I was getting a 0 reading. The alternator contacts looks pretty corroded so I will clean those up but I guess the question I have to get this conversation started is, how does the wrapped wire on the rotor go bad? It looks like it has some type of sealant covering the wires. Where does the stress come from to break the wire, if that is what's happening.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R100/7 Ignition rotor conversation

- Thread starter zelten

- Start date

6322

Member

My 1978 R100/7 was not charging the battery. I did some researched and I believe the ignition rotor is bad. When checked for resistance I was getting a 0 reading. The alternator contacts looks pretty corroded so I will clean those up but I guess the question I have to get this conversation started is, how does the wrapped wire on the rotor go bad? It looks like it has some type of sealant covering the wires. Where does the stress come from to break the wire, if that is what's happening.

Vibration also contributes as in motor or road vibration.

daveandcarel

New member

rotor resistance

Maybe I am reading this wrong, but a 0 for resistance of the rotor may be good. If the meter does not read very low resistance values accurately, 3-7 ohms might look like 0 ohms. Usually a bad rotor is open - infinite resistance.

Maybe I am reading this wrong, but a 0 for resistance of the rotor may be good. If the meter does not read very low resistance values accurately, 3-7 ohms might look like 0 ohms. Usually a bad rotor is open - infinite resistance.

Maybe I am reading this wrong, but a 0 for resistance of the rotor may be good. If the meter does not read very low resistance values accurately, 3-7 ohms might look like 0 ohms. Usually a bad rotor is open - infinite resistance.

I may be doing it wrong. I was basing it off this video.

https://youtu.be/oxQwx5EC5X4?t=435

As the guy in the video says, you should get some kind of number. Any reasonable digital voltmeter will show the number, either when using the auto scale or selecting the appropriate scale you expect to read.

What you might have missed in the video...I didn't see it all...is that you must isolate the brushes by raising them and slipping something underneath them, say a business card or thin piece of paper. Without the paper, you will be reading 0 ohms. For the R100/7, the reading for a stock system should be around 3.4 ohms.

What you might have missed in the video...I didn't see it all...is that you must isolate the brushes by raising them and slipping something underneath them, say a business card or thin piece of paper. Without the paper, you will be reading 0 ohms. For the R100/7, the reading for a stock system should be around 3.4 ohms.

When I put my multimeter to 200 then I get a reading of 3.7 so I think that is normal. On 2K it reads .002. On 20K it's 0.

happy wanderer

Day Dreaming ...

Good catch Kurt. I was about to reply the same thing. Measuring in situ only works if the rotor is isolated from the rest of the circuit.

Whenever I encounter a charging problem the first thing I check is the charging indicator. Does the light come on when the key is turned on? Does it go out when the bike is started? If the charge indicator bulb is blown and everything else is perfect the bike will not charge. Without any info on how you concluded the bike is not charging it's impossible to help trouble shoot it.

Another quick test is to jumper the regulator to determine if the regulator is bad or if the rotor, stator, diode board, worn brushes, bad battery or simply loose or corroded connections are to blame. Eliminating the regulator first is a good idea. You need a jumper that consists of two spade connectors on a 18AWG wire. On the regulator you will find a three prong triangle shaped connector. Pull it off and jumper between the two bottom connections across from each other. NOT the top of the triangle; the base. Fire up the bike and rev it to 2K at least. If you know your charge light is working and it goes out quickly when you rev the engine over 2K the regulator is toast and the problem lies elsewhere. You know you have a good rotor now so that ain't it.

Do this test and let us know what you find.

Another thing to do in the meantime is remove all the spade connectors in the charging system like on the diode board, regulator etc and check for corrosion or any kind. Clean them up, tighten them up a bit carefully and sometimes that is all that is wrong. Even loose battery post connections will cause charging issues.

And in the immortal words of DieselYoda... GROUNDS! Check the cluster of brown ground wires on the top spine of the frame. They are famous for causing electrical issues when corroded or loose.

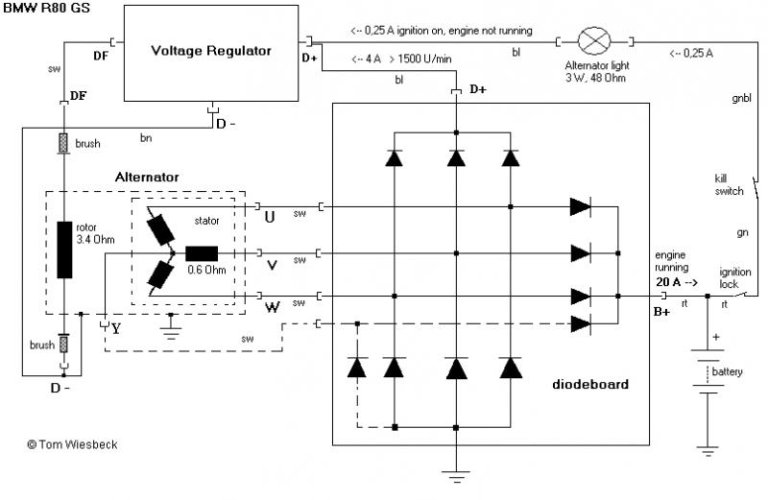

This might help too. The /7 is not very different and this helps visualize the components and how they work together. Well, it helps me anyway!

Last edited:

One problem I'm having with diagnosing my problem is I don't have an instrument cluster so I have no lights to tell me if it's charging. That was removed before I bought it. I have a lot of things I think are the problem, namely the aftermarket electric ignition system. But my question for today is, when unbolting and bolting the rotor in or out, should the rotor turn while tightening or loosening the bolt? I had to hold it still to keep it from turning. I'm not sure if it mattered, but I put it in 1st gear in hopes of holding it still but that didn't work. I carefully used a screw driver wedged between the rotor and housing to keep it from turning.

You can tell if the charging system is working by putting a voltmeter across the battery terminals. It should read roughly 12.5v with engine off. Then, with engine running, it should begin to increase in voltage as RPM increases. When you are at 3500 RPM or so, the voltage at the battery should be near 14v if not higher. Probably 13.7-13.8v would be OK. That indicates your charging system is working.

As for turning the engine, since you're turning a bolt that is at the tip of the crankshaft, it's reasonable to expect that the engine could turn. However, you're turning a very small bolt and as the crank turns, one of the pistons will begin to push against compression in that cylinder...hard to believe that turning the bolt could overcome the engine compression. In reality, the torque for this bolt is around 17 ft-lbs, although a value like 14-15 would be fine. The rotor fits onto a taper at the end of the crank...with the bolt tension, the taper keeps it from slipping.

I hope that using the use of the screwdriver didn't damage the rotor.

As for turning the engine, since you're turning a bolt that is at the tip of the crankshaft, it's reasonable to expect that the engine could turn. However, you're turning a very small bolt and as the crank turns, one of the pistons will begin to push against compression in that cylinder...hard to believe that turning the bolt could overcome the engine compression. In reality, the torque for this bolt is around 17 ft-lbs, although a value like 14-15 would be fine. The rotor fits onto a taper at the end of the crank...with the bolt tension, the taper keeps it from slipping.

I hope that using the use of the screwdriver didn't damage the rotor.

One of the many problems I'm having is getting the bike to start, even with a full charge. One more thing I'm looking into at the moment. And it leads me to believe it's something with the ignition system and maybe the charging system does work but I won't know until I get it started again.

As far as damaging the rotor, I highly doubt I did and I will know once I get the bike to start. There wasn't much pressure put on the bolt to loosen it once I was able to stop it from turning. I guess I just didn't turn it enough to let the engine build pressure to stop it. One more thing I have learned.

As far as damaging the rotor, I highly doubt I did and I will know once I get the bike to start. There wasn't much pressure put on the bolt to loosen it once I was able to stop it from turning. I guess I just didn't turn it enough to let the engine build pressure to stop it. One more thing I have learned.

pglaves

#13338

One of the many problems I'm having is getting the bike to start, even with a full charge. One more thing I'm looking into at the moment. And it leads me to believe it's something with the ignition system and maybe the charging system does work but I won't know until I get it started again.

As far as damaging the rotor, I highly doubt I did and I will know once I get the bike to start. There wasn't much pressure put on the bolt to loosen it once I was able to stop it from turning. I guess I just didn't turn it enough to let the engine build pressure to stop it. One more thing I have learned.

This requires a bystander but,

Put bike in gear

Helper holds rear brake

Turn rotor bolt

1074

Active member

Did you say that you do not have an instrument cluster and lights? And the bike won't start?

With all this discussion of rotor resistance and charging system, I think you've gotten onto the wrong course. Seems to me that the first thing is to have the instrument cluster with lights installed before you go anywhere else.

With all this discussion of rotor resistance and charging system, I think you've gotten onto the wrong course. Seems to me that the first thing is to have the instrument cluster with lights installed before you go anywhere else.

This requires a bystander but,

Put bike in gear

Helper holds rear brake

Turn rotor bolt

That's where I made my mistake

I have my bike on a stand and the rear wheel is off the ground...

I have my bike on a stand and the rear wheel is off the ground...

Did you say that you do not have an instrument cluster and lights? And the bike won't start?

With all this discussion of rotor resistance and charging system, I think you've gotten onto the wrong course. Seems to me that the first thing is to have the instrument cluster with lights installed before you go anywhere else.

Oh. it's a mess. I can get it to run after it turning over and backfiring multiple times and then it does pretty good after it gets going, but if I leave the battery alone, the battery dies. I don't know if it's not charging or something is draining it. The PO put a Dynatek Dyna III on it and so I have to see what is really happening. I'm just learning my way around these bikes so I have a lot to learn and electrics with any old vehicle is my ultimate weakness.

pglaves

#13338

I have a hunch - just a hunch mind you. But, the circuit which provides current through the rotor first goes through that little light bulb in the instrument cluster. Unless there has been some deliberate rewiring to provide the excitation current to the rotor other than through the cluster and that bulb, the system will not charge.

Similar threads

- Replies

- 5

- Views

- 798