jimvonbaden

Kool Aid Dispenser!

While not part of the BMW Service Schedule, it is a good idea to do this at the 6 or 12 K service. This is especially true if you do a lot of deep water crossings, ride in the rain often, or just put on a lot of miles. There have been cases of corrosion in the FD on several bikes, though not a large number by percentage, and even a failure of the FD splines on one bike due to corrosion. So, with that in mind, I decided to check a 14K mile and 6K mile GSw today. Here are the results, and general how-to:

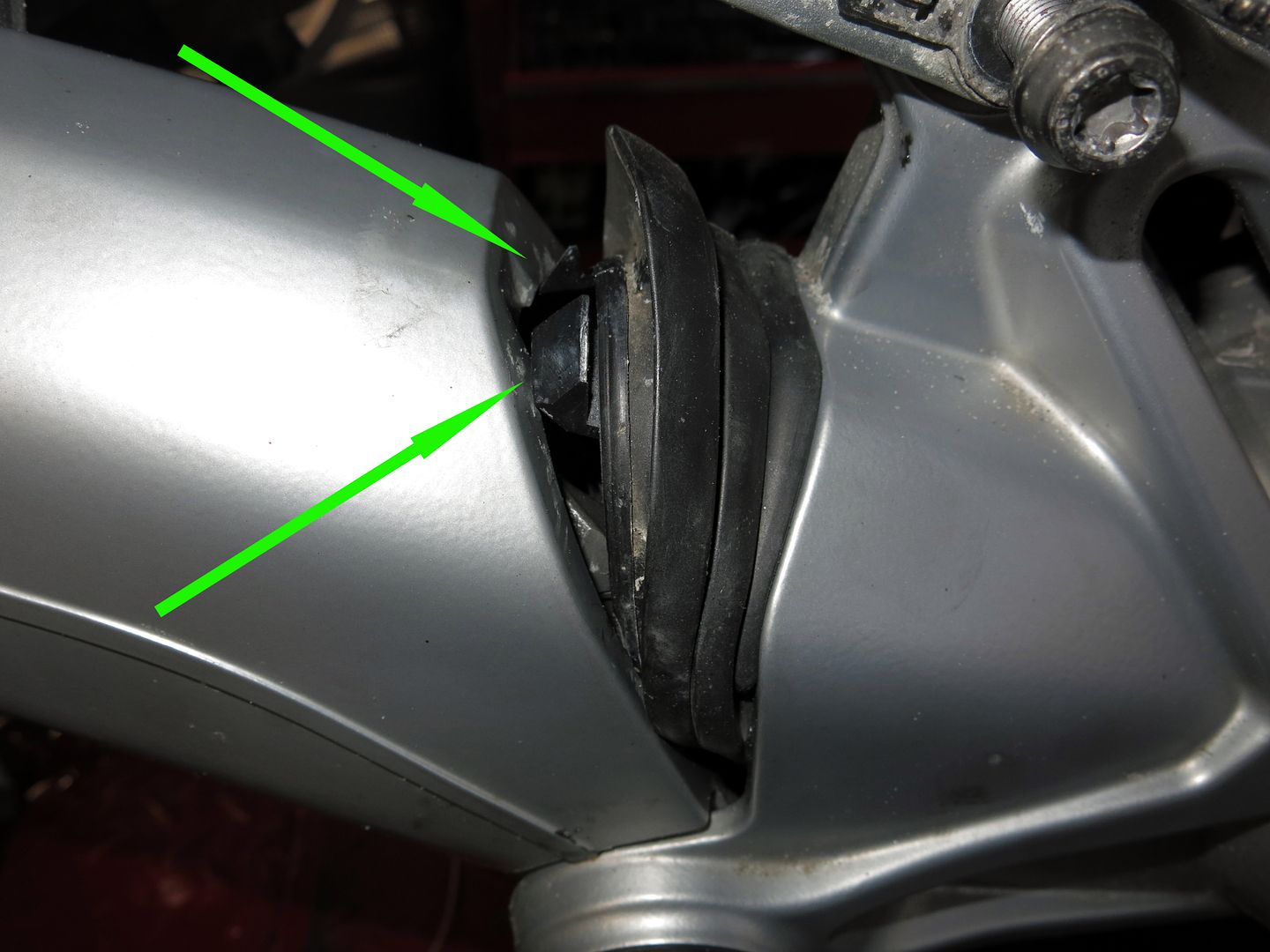

Pull the fender and wheel.

Then remove the speed sensor and the brake caliper:

Then hang the caliper out of the way:

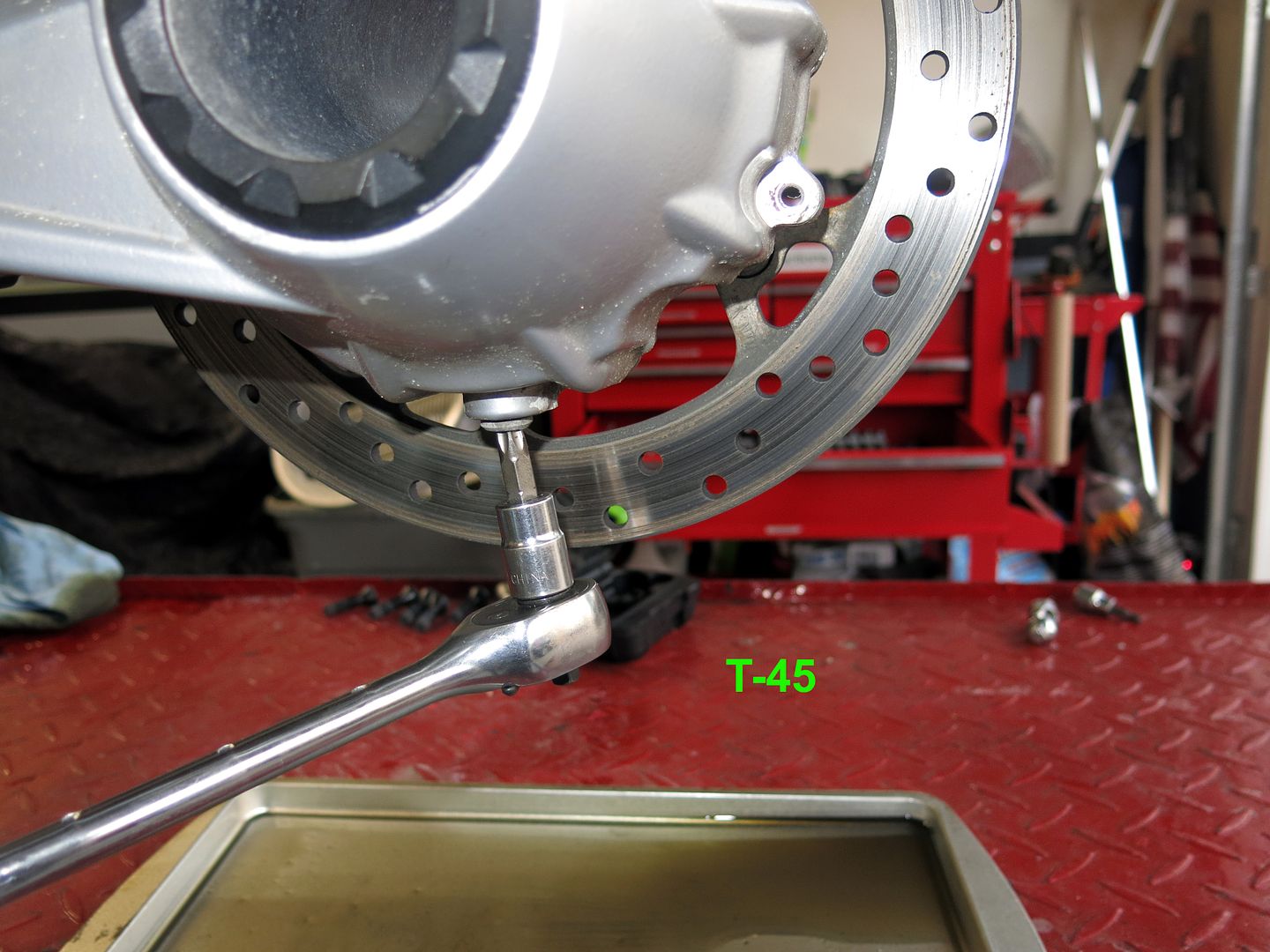

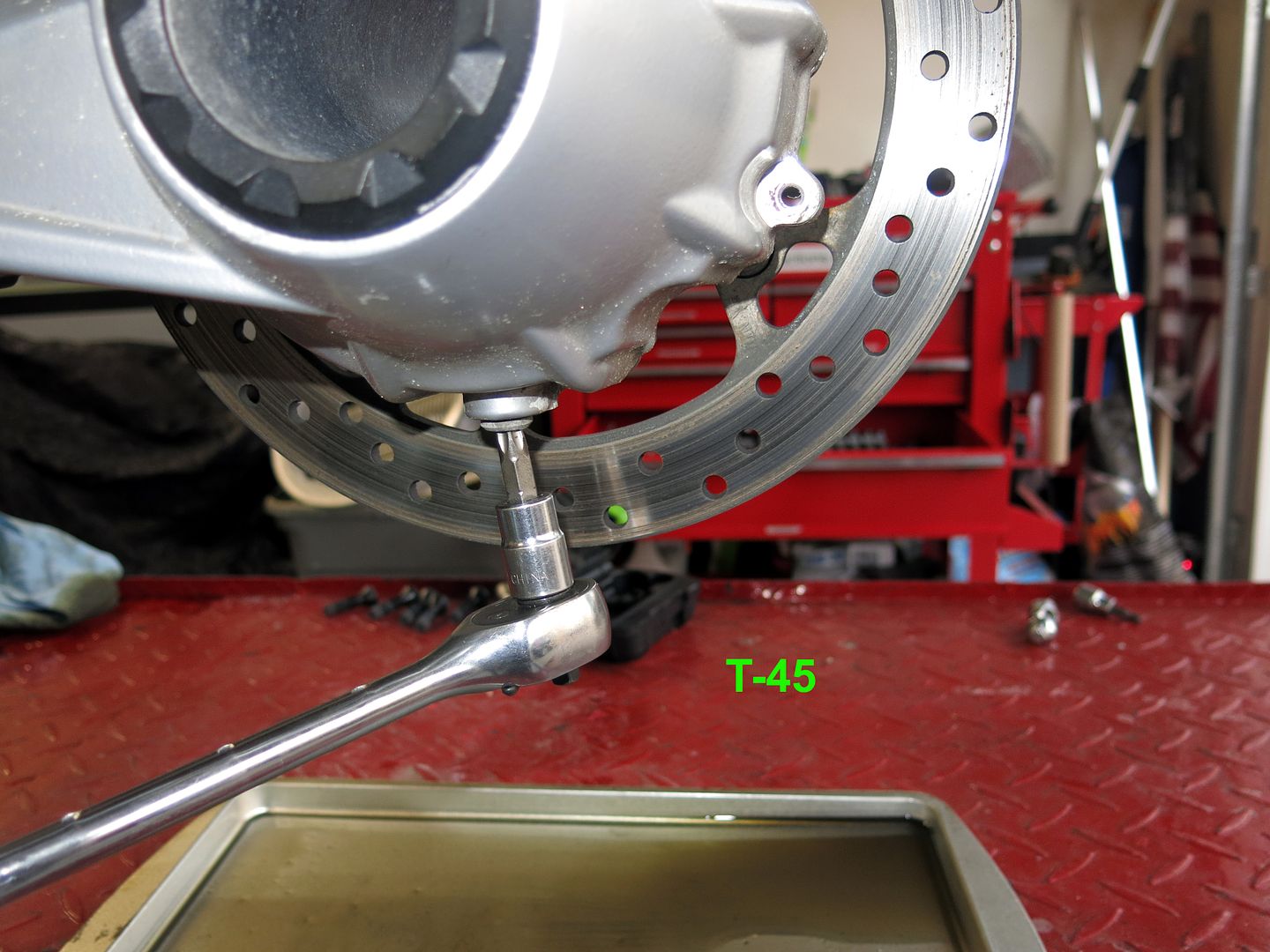

Next remove the drain and fill plugs:

<img src="http://i20.photobucket.com/albums/b238/JimVonBaden2000/JVB%20Productions/2015%20R1200GS/6K%20service/6K%20service%203-11-16%2019%20copy.jpg" border="0" alt=" photo 6K service 3-11-16 19 copy.jpg"/>

Then pull the bolt holding the Paralink bolt to the final drive:

Be prepared for it to drop down as you pull the bolt. Sometimes it doesn't and you will have to pull the final drive down. Make sure you have a cookie sheet or tray below the FD. You want no more than 1" deep for a tray. No worries about the amount of fluid, it will be fine.

Now you can see the condition of the splines, and the area inside the final drive. Both bikes looked exactly like this, and the 14K mile bike had a lot of off roading, presumably with water crossings. If you find oil in the swingarm, look up inside and see if there is an oil trail. If so, it will be the transmission output seal. If not, look at the dropped final drive for wet oil indicating a leaking final drive input seal.

Time to lube the spline, even if they have lube. Use a Moly based lube like I did:

No need to go nuts, a thin layer is fine.

(continued)

Pull the fender and wheel.

Then remove the speed sensor and the brake caliper:

Then hang the caliper out of the way:

Next remove the drain and fill plugs:

<img src="http://i20.photobucket.com/albums/b238/JimVonBaden2000/JVB%20Productions/2015%20R1200GS/6K%20service/6K%20service%203-11-16%2019%20copy.jpg" border="0" alt=" photo 6K service 3-11-16 19 copy.jpg"/>

Then pull the bolt holding the Paralink bolt to the final drive:

Be prepared for it to drop down as you pull the bolt. Sometimes it doesn't and you will have to pull the final drive down. Make sure you have a cookie sheet or tray below the FD. You want no more than 1" deep for a tray. No worries about the amount of fluid, it will be fine.

Now you can see the condition of the splines, and the area inside the final drive. Both bikes looked exactly like this, and the 14K mile bike had a lot of off roading, presumably with water crossings. If you find oil in the swingarm, look up inside and see if there is an oil trail. If so, it will be the transmission output seal. If not, look at the dropped final drive for wet oil indicating a leaking final drive input seal.

Time to lube the spline, even if they have lube. Use a Moly based lube like I did:

No need to go nuts, a thin layer is fine.

(continued)