Folks,

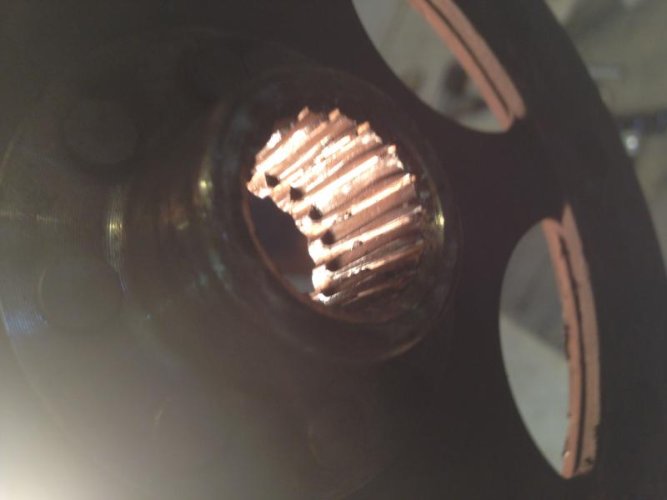

Just a thought after visiting with Roger04T. I recently removed my transmission to inspect for spline wear and found the inevitable. With the transmission removed I held the original clutch disk on the input shaft and measured the radial play/movement of the clutch disc at 5/8" radial backlash. I then installed a new clutch with a 5mm spacer and measured < 1/16" radial backlash.

What are peoples thoughts as whether this radial backlash would indicate the condition of clutch & input splines. I have photos of mine which I could share. Just wanted to get the topic started for discussion.

Just a thought after visiting with Roger04T. I recently removed my transmission to inspect for spline wear and found the inevitable. With the transmission removed I held the original clutch disk on the input shaft and measured the radial play/movement of the clutch disc at 5/8" radial backlash. I then installed a new clutch with a 5mm spacer and measured < 1/16" radial backlash.

What are peoples thoughts as whether this radial backlash would indicate the condition of clutch & input splines. I have photos of mine which I could share. Just wanted to get the topic started for discussion.