Emoto

New member

World Class Protection for your GS

Big Adventure bikes are all the rage. They are flying out of showrooms like nobody's business. The king of them all is the BMW GS series; the numbers don't lie. From its inception with the R80G/S on through the years to today's 1200cc liquid-cooled marvel, the GS has been the one that other motorcycle manufacturers seek to emulate, and hope to knock off the top of the hill with their own offering, for those who dare. Some have come close in one area or another, but nobody has managed to match the overall superb balance, and Swiss Army Knife utility of the BMW GS. Tour - even two-up - spend hours scratching the twisty backroads at speed, or explore that old dirt road that you always wondered about. The GS does it all, and in style.

Very few of us started off our riding careers on a GS. If the statistics are to be believed, most of us started on an inexpensive smaller displacement Japanese bike of one kind or another, and then progressed through various other bikes until we found the GS. Along the way, many (most?) of us have dropped our faithful steeds. Maybe it was just a tipover in the driveway, or maybe you hit a slick spot while turning. No matter how it happened, we all discovered that even a low speed tipover can can cause expensive damage, and may make the bike unridable, leaving you stranded.

With the GS, we have a bike that is more than just a street bike. The GS is a bike that intrepid riders will use to tempt fate on forest roads, single track trails, and more, all of which raise the chances of dropping the bike or hitting a rock or other object with the engine. It is one thing to have a mishap at the local coffee shop, but quite another if you're miles away from the main road with no cell service. Even so, those of us who are less adventurous can still dump the bike in the mall parking lot, and if the cylinder head cover cracks, you're losing engine oil, and may need a tow. Clearly, some sort of protection is in order. BMW owners have a lot of

options when choosing accessories, so discretion and care are needed to make the best choice.

Having worked to accessorize a couple of GSes over the years, I have had the chance to examine and try the products of a number of companies. Some try to stake out the low end of the price scale, and end up proving that you get what you pay for, with imperfect fit and/or a tendency to rust when scratched. And let's face it, most of us are going to put a few scratches on our crash bars and skid plates, no matter how careful we try to be as we tiptoe around the Starbucks parking lot while on safari, so mild steel is out, at least for me. The other consideration is how a product affects service tasks on the bike. Do you really want to spend a extra time performing routine maintenance, or worse, pay a shop extra to do the work for you, simply because of an accessory choice? More on this later.

Enter AltRider (AltRider EU for non-US folks) and their Crash Bar and Skid Plate System for the BMW R 1200 GS Water Cooled. This is a kit containing both their engine crash bars and their skid plate, at about a fifty dollar savings, depending on finish, over buying the parts individually. The crash bars are made of stainless steel, so will not rust if you scratch them. And if you do scratch them, a little time with some sandpaper or a buffer will fix them right up. Of note is that the crash bars are made of 1.25" diameter tubing, which is the largest used in crash bars on the market, as far as I have been able to tell. They do this because it helps control flex better than with smaller diameter bars, and that allows them to be located a little closer to what they are protecting, which gives a cleaner overall look. Best of all, you can remove the valve covers for valve adjustment without having to remove the bars. Good news, no matter who works on your bike!

The skid plate is made from beefy 3/16" (4.76mm) aluminum and is designed to provide protection over the entire underside of the engine, as well as the catalytic converter. Of particular interest is the fact that there are no fasteners on the bottom of the skid plate, which is an excellent feature, because boltheads on skid plates tend to end up smashed and deformed, making removal much more of a challenge. Eliminating that is the kind of clever design that I appreciate. Another excellent feature is that you do not have to remove the skid plate to perform an oil and filter change. They have designed a small cutout in the bottom to access the drain plug and allow the oil to drain, and the side-mounted oil filter is not obstructed either. That is a good little time-saver that will pay off as long as you own the bike.

The kit ships in two big boxes, and the contents are packed with the care that I have come to expect from AltRider. One of the things I noticed is that the packing material they use to keep the items from moving around in the boxes is simple brown paper. This is so much better and more environmentally friendly that those awful styrofoam peanuts that some of the other accessory makers use. Sure, they use plastic bags and bubble wrap where called for, but they don't use plastic where it isn't necessary. I am not a nut about environmental issues, but I appreciate it when the people I do business with take the time to do things in a good environmentally conscious way. It means that someone at AltRider is thinking, and that is a good thing.

Once you have the boxes open, and things laid out, you will want to review the instructions from front to back and familiarize yourself with the tasks involved. There is nothing here that the average Joe with hand tools can't accomplish in an afternoon, but you will not want to rush through things, because alignment of the components is important to get right, or you may need to employ some salty language later. Make sure you follow the crashbar alignment instructions very carefully.

Note that on lower right corner of the front page of the printed instructions there is a rev number. This is the revision number for the instructions, so you want the highest number available. Check the versions online here for crash bars and here for the skid plate, and if the online ones have a higher rev number, print them out and use them instead of what came in the boxes. This will ensure that you have the best instructions available. I like that AltRider strives to improve the instructions on an ongoing basis.

Included are small containers of thread locking agent and anti-seize compound. As far as I know, nobody else provides small touches like these. Although I already had some of each on hand, their inclusion means that everyone who gets this kit will be able to do a good job and not be tempted to skip using them, if they don't have any. I also want to mention that the kit comes with a couple of torx bits as well, which can be of help if your tool selection is limited.

Crash Bars

The first thing to do is to bolt the crash bars onto their mounting brackets. Use the provided 8mm hexhead bolts with washers. Put a small amount of thread locking compound on the threads. NOTE: Follow the AltRider instructions carefully on this step, if you are also mounting the skid plate. There is detail provided about centering the bolts precisely that must be followed if you are to avoid undoing and redoing some steps to make the skid plate holes align correctly later on. I eyeballed it when centering the bars on the mounts, and it worked out ok for me, but I strongly recommend following their alignment instructions. Those bolt heads will end up in a hard

to access spot, so best to go slowly and get it right. Torque them to 25 nm.

The next step is to remove the long engine mounting bolt that sits just above and aft of the cylinders. This will require an 18mm socket on the left and a T55 torx bit on the right. You may find, as I did, that the nut on this bolt had apparently been torqued by gorillas; I had to use a breaker bar with a pipe... er... "torque amplifier" on it to break it free. Others have not mentioned this, so maybe I was just lucky. Once you get it loose, it is removed from the right side. As was recommended in the instructions, I used a 1/4" extension to push it out, but you can use anything on hand to push with, such as a wooden dowel.

The next step is removing the two 10mm lower engine mounting bolts. I started on the left side. CAUTION: Only do this on one side at a time. Do not remove the other side, until after you have the bolts from the first side back in place. Taking out both sides at once can allow the engine to shift in the frame and then your bolt holes won't line up anymore, so don't do that!

The next step is mounting the left side crash bar. A new, longer engine mounting bolt is provided. It has a nut already in place on one end. Leave that nut just where it is. The washers/spacers that were on the OEM bolt are not reused. Hold the crash bar up in place and run the new bolt through it. Once that bolt has been pushed through, it will hold up the bar and

allow you to attend to the other fasteners. Don't worry about putting the nut on the other end until after you've finished doing the left side crash bar.

Next, attach the front upper fasteners using the provided socket head bolts, nuts, and washers. My 2013 GS uses two bolts on each side, but there may have been some frame changes for 2014 and beyond, so those models may only have a single hole. If that is the case, just use one bolt on

each side. You will need a 6mm allen for the bolt, and a 13mm for the nut. Don't worry about the coolant hose; there is room to sneak your allen wrench past it, just push on the hose a little and it will yield fairly easily. Don't tighten them all the way, yet. Note: The left side bar goes outboard of the frame, but the right side bar goes inboard of the frame.

Now do the lower forward fastener. This will require an 8x50mm bolt, a washer, and one of the two spacers. The washer goes on the bolt, then the bolt goes through the crash bar bracket, and the spacer holds the bracket away from the engine. Put some anti-seize on the bolt. You don't need a lot of it; a little goes a long way. Don't tighten it up all the way, yet.

Now put the original lower engine mounting bolts back in. Clean up the bolts and threads as best you can, then put a little thread locking compound on them, and run them in. Don't tighten them all the way yet. Be sure to start these bolts by hand, in order to be sure that you don't cross-thread them. You are threading hard steel into soft aluminum, so be patient and get it right.

Now go back to the forward upper and lower bolts and torque them to 10 nm. After you've done those, torque the two 10mm engine bolts to 55 nm. The left side is now complete, and it is time to do the right side.

First, remove the two lower frame mounting bolts like you did on the left side. Just as you did with the left, hang the right side bar onto the long upper bolt that you slid through the frame, then thread the 18mm nut onto it. Don't tighten it all the way yet.

Then, using the two socket head bolts, washers, and nuts, attach the upper forward part of the bar to the frame. Remember, that this one on the right side mounts on the inside of the frame bracket. You'll need a 6mm allen and a 13mm wrench or socket. Again, leave them a little loose for now.

Take the remaining 8x50 bolt, washer, and spacer and use them to attach the lower forward part of the mounting bracket to the bike, just like you did on the left side. Use a little anti-seize compound on the bolt.

Now you can put the original lower engine mounting bolts back in. Clean up the bolts and threads as best you can, then put a little thread locking compound on them, and run them in. Don't tighten them all the way yet. Be sure to start these bolts by hand, in order to be sure that you don't cross-thread them. You are threading hard steel into soft aluminum, so be patient and get it right.

Go back to the forward upper and lower bolts and torque them to 10 nm. After you've done those, torque the two 10mm engine bolts to 55 nm. Then, take a 13mm wrench and reach up behind the mounting plates and make sure that the bolts that you used to attach the bars to the brackets in the very first step are tight - do this on both sides.

Get two 18mm sockets and use them to finish tightening that long upper bolt that runs through the frame to 85 nm. Remember, there is a nut on each end of that new bolt, so that's why you need two sockets.

That's it, you're done!

Skid Plate

The new AltRider skid plate for the liquid cooled GS is a departure from past designs. It has been designed to provide maximum coverage and protection without sacrificing ground clearance or cornering, and does not interfere with maintenance tasks. The AltRider skid plate protects not only the underside of the engine, but also extends far back to protect the catalytic converter, and has sides that curve up to protect the header pipes. AltRider has devised a clever and sturdy way to mount the plate so that it does not transfer any force to the engine. Instead, it mounts to the beefy stainless brackets for the crash bars that bolt to the frame, and to some

replacement centerstand pivots. The bottom of the skid plate is flat and does not have any bolts or fasteners to be deformed when the skid plate takes a hit. This is a terrific design, but (as those guys on the TV commercials always say) wait, there's more! The AltRider skid plate is

designed with engine oil drain bolt access, so you do not have to take the skid plate off to perform an oil change! And yes, I am unashamedly enthusiastic, because they seem to have thought of everything.

To say that the skid plate for the new liquid cooled GS is a an improvement over the stock BMW one is like saying that filet mignon is better than a McDonald's burger. It sounds like exaggeration, but just look at the difference between the two! It is almost ridiculous to compare them.

Not only does the AltRider plate extend much farther than the BMW one, but it is made of much thicker (3/16") material, so will stand up to far more abuse than the tiny, thin BMW plate.

As always, there is an excellent set of printed instructions provided. Note that on lower right corner of the front page of the printed instructions there is a rev number. This is the revision number for the instructions, so you want the highest number available. Check the versions online here for the skid plate, and if the online ones have a higher rev number, print them out and use them instead of what came in the box. This will ensure that you have the best instructions available.

The first step is to remove the old skid plate and all of the brackets it attaches to. I recommend you put it all in a plastic bag and tuck it away on a shelf somewhere to gather dust. You can always put it back on if you sell the bike someday an want to keep the AltRider piece.

The instructions go into some detail about making sure you followed the alignment steps carefully for the crash bars, if you are mounting both products. They're not kidding, follow those alignment steps as carefully as you can, or the skid plate holes won't line up with the mount plate nuts or centerstand pivots.

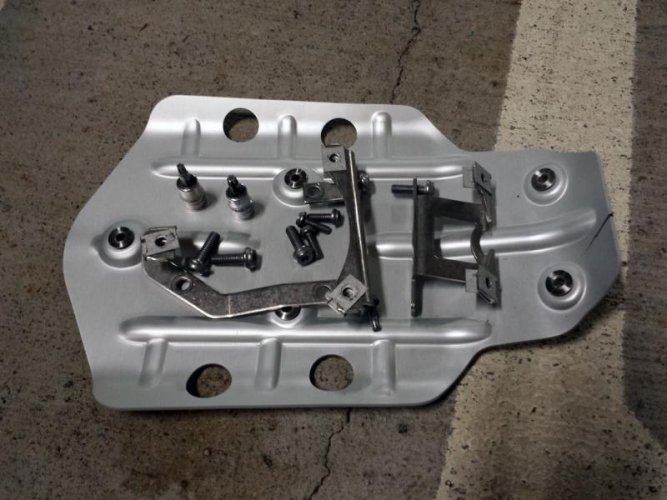

If you are only installing the skid plate, and do NOT have the AltRider crash bars, then you will need to remove the two 10mm lower engine mounting bolts from one side (start on the left) and then attach the provided mount for the skid plate, which is similar to the one pictured above for the crash bars, but a little smaller. CAUTION: Only do this on one side at a time. Do not remove the other side, until after you have the bolts from the first side back in place. Taking out both sides at once can allow the engine to shift in the frame and then your bolt holes won't line up anymore, so don't do that!

The next step is going to involve replacing the centerstand pivots with ones that AltRider provides. In order to take the stress off of those pivots, which will make the job easier, the following steps are done with the bike on the side stand, so if it isn't already, put it on the sidestand.

To access the pivot on the right side (which is where they suggest you start) you will need to depress the rear brake pedal a bit, because it is in the way. You can either remove the pedal, or grab the rear brake caliper and wiggle it back and forth some and gradually compress it. Once

you've done that, it will be easier to push that rear brake pedal down.

Remove the right side centerstand pivot first. The pivots are held in by a circlip, sometimes called a snap ring. You will want to use circlip pliers (some auto parts stores loan them out for free) or I suppose you could use a couple of strong picks, but the pliers are not terribly expensive and are nice to have.

Remove the circlip, then use an object about the diameter of the pivot, like a deep 12 or 13mm socket to drive out the pivot while maintaining alignment of the centerstand parts. In the image below, you can see that I had a ratchet extension in the socket that I was using to drive out the old pivot. I tapped lightly on the extension to drive out the pivot.

Lubricate the new AltRider pivot, then drive it into place and allow it to simultaneously drive out the socket that is now in the place of the OEM pivot. I used moly, but any good grease will do just fine. In the picture below, you can see that I used a soft brass hammer, and you can see

the socket coming out the back. Be careful as you tap, because the new pivot is aluminum, so will deform if you strike it too hard. Luckily, there is not a great deal of force required. The picture is of the left side, but do start on the right, as recommended.

Once the pivot has been driven all the way home, re-use the original circlip and put it back in place. Repeat the process for the pivot on the other side of the bike.

Now it is time to mount the skid plate itself. The first step will be to loosely attach it to the forward mounts using the provided socket head bolts and washers - two on each side. If you have someone to hold it up for you, great, but I found that I could use my knee to hold it up. Leave the bolts loose, so you can wiggle it around a bit if necessary. Note how the skid plate comes up and wraps around the header pipes, protecting them in the process. Not every skid plate does that.

Now it's time to bolt the back of the skid plate to the new pivots you installed above. Do this with the bike on the sidestand. Use a hexhead bolt and washer on the right, and a pan head (countersunk style) on the left. Use thread locking agent on both bolts. This step is the trickiest part of the installation because you have to reach in and thread the bolts in from

behind. Take your time and be patient, so that you don't cross-thread them. You can put a 5mm allen wrench into the hole on the outside of the pivots and use that for leverage and even turning as you tighten. AltRider says to torque the bolts and not the pivots. I think that is because the pivots have some pressure on them from the centerstand, so will not give you an accurate feel as you tighten. If things don't line up, try jiggling the skid plate around some, but you may have to go back and re-align things according to the first steps again.

At this point, you must go back and torque all of the fasteners.

First tighten the 8mm bracket bolts to 13 nm, and then tighten the 10 mm frame bolts to 55 nm, then go back to the 4 8mm skid plate mounting bolts and take them to 13 nm.

Congratulations, you're done!

Conclusion

The AltRider crash bars and skid plate are the real deal. They are heavy-duty pieces, available in either silver or black, designed and built to take real punishment and laugh it off. They offer a unique combination of full coverage protection without impeding routine maintenance. These AltRider products are designed and made in the USA, and display a level of fit, finish, and build quality that exceeds that of any other brand I have seen, and yes, that includes those famous German names we all know. I did have a question as I went about this installation and am happy to report that I received a reply to my email within a day or so that actually answered my question, so it seems that customer support is good, as well. All in all, I am very happy to have these parts on my bike, and look forward to many years of good service from them. With products as nice as these, with all the little touches like including thread locking agent, anti-seize,

torx bits, clear detailed instructions with crisp photos and required tools lists, I expect that AltRider will grow to become a major player in the Adventure Riding field, and I say it is about time that there was a David to challenge the various Goliaths of the accessory market that we've all grown so used to.

A Happy GSW with its new AltRider Crash Bars and Skid Plate!

Author's Note: I make my living as a technical writer, creating mind-numbingly dry and boring software manuals for the financial services industry that are entirely devoid of humor or creativity. If more people read my manuals, insomnia would not exist! I write little reviews like this one purely for fun, as a kind of antidote for the writing I must do on a daily basis. I have no financial interest in any of the companies whose products I write about, nor am I on their payrolls. The information presented is my personal opinion, and mine alone. I hope you enjoyed it and found it informative! Farkle on, my friends!

See this review on my little web site here: http://home.comcast.net/~emoto1/AltRiderSkidPlateCrashBars.htm

Big Adventure bikes are all the rage. They are flying out of showrooms like nobody's business. The king of them all is the BMW GS series; the numbers don't lie. From its inception with the R80G/S on through the years to today's 1200cc liquid-cooled marvel, the GS has been the one that other motorcycle manufacturers seek to emulate, and hope to knock off the top of the hill with their own offering, for those who dare. Some have come close in one area or another, but nobody has managed to match the overall superb balance, and Swiss Army Knife utility of the BMW GS. Tour - even two-up - spend hours scratching the twisty backroads at speed, or explore that old dirt road that you always wondered about. The GS does it all, and in style.

Very few of us started off our riding careers on a GS. If the statistics are to be believed, most of us started on an inexpensive smaller displacement Japanese bike of one kind or another, and then progressed through various other bikes until we found the GS. Along the way, many (most?) of us have dropped our faithful steeds. Maybe it was just a tipover in the driveway, or maybe you hit a slick spot while turning. No matter how it happened, we all discovered that even a low speed tipover can can cause expensive damage, and may make the bike unridable, leaving you stranded.

With the GS, we have a bike that is more than just a street bike. The GS is a bike that intrepid riders will use to tempt fate on forest roads, single track trails, and more, all of which raise the chances of dropping the bike or hitting a rock or other object with the engine. It is one thing to have a mishap at the local coffee shop, but quite another if you're miles away from the main road with no cell service. Even so, those of us who are less adventurous can still dump the bike in the mall parking lot, and if the cylinder head cover cracks, you're losing engine oil, and may need a tow. Clearly, some sort of protection is in order. BMW owners have a lot of

options when choosing accessories, so discretion and care are needed to make the best choice.

Having worked to accessorize a couple of GSes over the years, I have had the chance to examine and try the products of a number of companies. Some try to stake out the low end of the price scale, and end up proving that you get what you pay for, with imperfect fit and/or a tendency to rust when scratched. And let's face it, most of us are going to put a few scratches on our crash bars and skid plates, no matter how careful we try to be as we tiptoe around the Starbucks parking lot while on safari, so mild steel is out, at least for me. The other consideration is how a product affects service tasks on the bike. Do you really want to spend a extra time performing routine maintenance, or worse, pay a shop extra to do the work for you, simply because of an accessory choice? More on this later.

Enter AltRider (AltRider EU for non-US folks) and their Crash Bar and Skid Plate System for the BMW R 1200 GS Water Cooled. This is a kit containing both their engine crash bars and their skid plate, at about a fifty dollar savings, depending on finish, over buying the parts individually. The crash bars are made of stainless steel, so will not rust if you scratch them. And if you do scratch them, a little time with some sandpaper or a buffer will fix them right up. Of note is that the crash bars are made of 1.25" diameter tubing, which is the largest used in crash bars on the market, as far as I have been able to tell. They do this because it helps control flex better than with smaller diameter bars, and that allows them to be located a little closer to what they are protecting, which gives a cleaner overall look. Best of all, you can remove the valve covers for valve adjustment without having to remove the bars. Good news, no matter who works on your bike!

The skid plate is made from beefy 3/16" (4.76mm) aluminum and is designed to provide protection over the entire underside of the engine, as well as the catalytic converter. Of particular interest is the fact that there are no fasteners on the bottom of the skid plate, which is an excellent feature, because boltheads on skid plates tend to end up smashed and deformed, making removal much more of a challenge. Eliminating that is the kind of clever design that I appreciate. Another excellent feature is that you do not have to remove the skid plate to perform an oil and filter change. They have designed a small cutout in the bottom to access the drain plug and allow the oil to drain, and the side-mounted oil filter is not obstructed either. That is a good little time-saver that will pay off as long as you own the bike.

The kit ships in two big boxes, and the contents are packed with the care that I have come to expect from AltRider. One of the things I noticed is that the packing material they use to keep the items from moving around in the boxes is simple brown paper. This is so much better and more environmentally friendly that those awful styrofoam peanuts that some of the other accessory makers use. Sure, they use plastic bags and bubble wrap where called for, but they don't use plastic where it isn't necessary. I am not a nut about environmental issues, but I appreciate it when the people I do business with take the time to do things in a good environmentally conscious way. It means that someone at AltRider is thinking, and that is a good thing.

Once you have the boxes open, and things laid out, you will want to review the instructions from front to back and familiarize yourself with the tasks involved. There is nothing here that the average Joe with hand tools can't accomplish in an afternoon, but you will not want to rush through things, because alignment of the components is important to get right, or you may need to employ some salty language later. Make sure you follow the crashbar alignment instructions very carefully.

Note that on lower right corner of the front page of the printed instructions there is a rev number. This is the revision number for the instructions, so you want the highest number available. Check the versions online here for crash bars and here for the skid plate, and if the online ones have a higher rev number, print them out and use them instead of what came in the boxes. This will ensure that you have the best instructions available. I like that AltRider strives to improve the instructions on an ongoing basis.

Included are small containers of thread locking agent and anti-seize compound. As far as I know, nobody else provides small touches like these. Although I already had some of each on hand, their inclusion means that everyone who gets this kit will be able to do a good job and not be tempted to skip using them, if they don't have any. I also want to mention that the kit comes with a couple of torx bits as well, which can be of help if your tool selection is limited.

Crash Bars

The first thing to do is to bolt the crash bars onto their mounting brackets. Use the provided 8mm hexhead bolts with washers. Put a small amount of thread locking compound on the threads. NOTE: Follow the AltRider instructions carefully on this step, if you are also mounting the skid plate. There is detail provided about centering the bolts precisely that must be followed if you are to avoid undoing and redoing some steps to make the skid plate holes align correctly later on. I eyeballed it when centering the bars on the mounts, and it worked out ok for me, but I strongly recommend following their alignment instructions. Those bolt heads will end up in a hard

to access spot, so best to go slowly and get it right. Torque them to 25 nm.

The next step is to remove the long engine mounting bolt that sits just above and aft of the cylinders. This will require an 18mm socket on the left and a T55 torx bit on the right. You may find, as I did, that the nut on this bolt had apparently been torqued by gorillas; I had to use a breaker bar with a pipe... er... "torque amplifier" on it to break it free. Others have not mentioned this, so maybe I was just lucky. Once you get it loose, it is removed from the right side. As was recommended in the instructions, I used a 1/4" extension to push it out, but you can use anything on hand to push with, such as a wooden dowel.

The next step is removing the two 10mm lower engine mounting bolts. I started on the left side. CAUTION: Only do this on one side at a time. Do not remove the other side, until after you have the bolts from the first side back in place. Taking out both sides at once can allow the engine to shift in the frame and then your bolt holes won't line up anymore, so don't do that!

The next step is mounting the left side crash bar. A new, longer engine mounting bolt is provided. It has a nut already in place on one end. Leave that nut just where it is. The washers/spacers that were on the OEM bolt are not reused. Hold the crash bar up in place and run the new bolt through it. Once that bolt has been pushed through, it will hold up the bar and

allow you to attend to the other fasteners. Don't worry about putting the nut on the other end until after you've finished doing the left side crash bar.

Next, attach the front upper fasteners using the provided socket head bolts, nuts, and washers. My 2013 GS uses two bolts on each side, but there may have been some frame changes for 2014 and beyond, so those models may only have a single hole. If that is the case, just use one bolt on

each side. You will need a 6mm allen for the bolt, and a 13mm for the nut. Don't worry about the coolant hose; there is room to sneak your allen wrench past it, just push on the hose a little and it will yield fairly easily. Don't tighten them all the way, yet. Note: The left side bar goes outboard of the frame, but the right side bar goes inboard of the frame.

Now do the lower forward fastener. This will require an 8x50mm bolt, a washer, and one of the two spacers. The washer goes on the bolt, then the bolt goes through the crash bar bracket, and the spacer holds the bracket away from the engine. Put some anti-seize on the bolt. You don't need a lot of it; a little goes a long way. Don't tighten it up all the way, yet.

Now put the original lower engine mounting bolts back in. Clean up the bolts and threads as best you can, then put a little thread locking compound on them, and run them in. Don't tighten them all the way yet. Be sure to start these bolts by hand, in order to be sure that you don't cross-thread them. You are threading hard steel into soft aluminum, so be patient and get it right.

Now go back to the forward upper and lower bolts and torque them to 10 nm. After you've done those, torque the two 10mm engine bolts to 55 nm. The left side is now complete, and it is time to do the right side.

First, remove the two lower frame mounting bolts like you did on the left side. Just as you did with the left, hang the right side bar onto the long upper bolt that you slid through the frame, then thread the 18mm nut onto it. Don't tighten it all the way yet.

Then, using the two socket head bolts, washers, and nuts, attach the upper forward part of the bar to the frame. Remember, that this one on the right side mounts on the inside of the frame bracket. You'll need a 6mm allen and a 13mm wrench or socket. Again, leave them a little loose for now.

Take the remaining 8x50 bolt, washer, and spacer and use them to attach the lower forward part of the mounting bracket to the bike, just like you did on the left side. Use a little anti-seize compound on the bolt.

Now you can put the original lower engine mounting bolts back in. Clean up the bolts and threads as best you can, then put a little thread locking compound on them, and run them in. Don't tighten them all the way yet. Be sure to start these bolts by hand, in order to be sure that you don't cross-thread them. You are threading hard steel into soft aluminum, so be patient and get it right.

Go back to the forward upper and lower bolts and torque them to 10 nm. After you've done those, torque the two 10mm engine bolts to 55 nm. Then, take a 13mm wrench and reach up behind the mounting plates and make sure that the bolts that you used to attach the bars to the brackets in the very first step are tight - do this on both sides.

Get two 18mm sockets and use them to finish tightening that long upper bolt that runs through the frame to 85 nm. Remember, there is a nut on each end of that new bolt, so that's why you need two sockets.

That's it, you're done!

Skid Plate

The new AltRider skid plate for the liquid cooled GS is a departure from past designs. It has been designed to provide maximum coverage and protection without sacrificing ground clearance or cornering, and does not interfere with maintenance tasks. The AltRider skid plate protects not only the underside of the engine, but also extends far back to protect the catalytic converter, and has sides that curve up to protect the header pipes. AltRider has devised a clever and sturdy way to mount the plate so that it does not transfer any force to the engine. Instead, it mounts to the beefy stainless brackets for the crash bars that bolt to the frame, and to some

replacement centerstand pivots. The bottom of the skid plate is flat and does not have any bolts or fasteners to be deformed when the skid plate takes a hit. This is a terrific design, but (as those guys on the TV commercials always say) wait, there's more! The AltRider skid plate is

designed with engine oil drain bolt access, so you do not have to take the skid plate off to perform an oil change! And yes, I am unashamedly enthusiastic, because they seem to have thought of everything.

To say that the skid plate for the new liquid cooled GS is a an improvement over the stock BMW one is like saying that filet mignon is better than a McDonald's burger. It sounds like exaggeration, but just look at the difference between the two! It is almost ridiculous to compare them.

Not only does the AltRider plate extend much farther than the BMW one, but it is made of much thicker (3/16") material, so will stand up to far more abuse than the tiny, thin BMW plate.

As always, there is an excellent set of printed instructions provided. Note that on lower right corner of the front page of the printed instructions there is a rev number. This is the revision number for the instructions, so you want the highest number available. Check the versions online here for the skid plate, and if the online ones have a higher rev number, print them out and use them instead of what came in the box. This will ensure that you have the best instructions available.

The first step is to remove the old skid plate and all of the brackets it attaches to. I recommend you put it all in a plastic bag and tuck it away on a shelf somewhere to gather dust. You can always put it back on if you sell the bike someday an want to keep the AltRider piece.

The instructions go into some detail about making sure you followed the alignment steps carefully for the crash bars, if you are mounting both products. They're not kidding, follow those alignment steps as carefully as you can, or the skid plate holes won't line up with the mount plate nuts or centerstand pivots.

If you are only installing the skid plate, and do NOT have the AltRider crash bars, then you will need to remove the two 10mm lower engine mounting bolts from one side (start on the left) and then attach the provided mount for the skid plate, which is similar to the one pictured above for the crash bars, but a little smaller. CAUTION: Only do this on one side at a time. Do not remove the other side, until after you have the bolts from the first side back in place. Taking out both sides at once can allow the engine to shift in the frame and then your bolt holes won't line up anymore, so don't do that!

The next step is going to involve replacing the centerstand pivots with ones that AltRider provides. In order to take the stress off of those pivots, which will make the job easier, the following steps are done with the bike on the side stand, so if it isn't already, put it on the sidestand.

To access the pivot on the right side (which is where they suggest you start) you will need to depress the rear brake pedal a bit, because it is in the way. You can either remove the pedal, or grab the rear brake caliper and wiggle it back and forth some and gradually compress it. Once

you've done that, it will be easier to push that rear brake pedal down.

Remove the right side centerstand pivot first. The pivots are held in by a circlip, sometimes called a snap ring. You will want to use circlip pliers (some auto parts stores loan them out for free) or I suppose you could use a couple of strong picks, but the pliers are not terribly expensive and are nice to have.

Remove the circlip, then use an object about the diameter of the pivot, like a deep 12 or 13mm socket to drive out the pivot while maintaining alignment of the centerstand parts. In the image below, you can see that I had a ratchet extension in the socket that I was using to drive out the old pivot. I tapped lightly on the extension to drive out the pivot.

Lubricate the new AltRider pivot, then drive it into place and allow it to simultaneously drive out the socket that is now in the place of the OEM pivot. I used moly, but any good grease will do just fine. In the picture below, you can see that I used a soft brass hammer, and you can see

the socket coming out the back. Be careful as you tap, because the new pivot is aluminum, so will deform if you strike it too hard. Luckily, there is not a great deal of force required. The picture is of the left side, but do start on the right, as recommended.

Once the pivot has been driven all the way home, re-use the original circlip and put it back in place. Repeat the process for the pivot on the other side of the bike.

Now it is time to mount the skid plate itself. The first step will be to loosely attach it to the forward mounts using the provided socket head bolts and washers - two on each side. If you have someone to hold it up for you, great, but I found that I could use my knee to hold it up. Leave the bolts loose, so you can wiggle it around a bit if necessary. Note how the skid plate comes up and wraps around the header pipes, protecting them in the process. Not every skid plate does that.

Now it's time to bolt the back of the skid plate to the new pivots you installed above. Do this with the bike on the sidestand. Use a hexhead bolt and washer on the right, and a pan head (countersunk style) on the left. Use thread locking agent on both bolts. This step is the trickiest part of the installation because you have to reach in and thread the bolts in from

behind. Take your time and be patient, so that you don't cross-thread them. You can put a 5mm allen wrench into the hole on the outside of the pivots and use that for leverage and even turning as you tighten. AltRider says to torque the bolts and not the pivots. I think that is because the pivots have some pressure on them from the centerstand, so will not give you an accurate feel as you tighten. If things don't line up, try jiggling the skid plate around some, but you may have to go back and re-align things according to the first steps again.

At this point, you must go back and torque all of the fasteners.

First tighten the 8mm bracket bolts to 13 nm, and then tighten the 10 mm frame bolts to 55 nm, then go back to the 4 8mm skid plate mounting bolts and take them to 13 nm.

Congratulations, you're done!

Conclusion

The AltRider crash bars and skid plate are the real deal. They are heavy-duty pieces, available in either silver or black, designed and built to take real punishment and laugh it off. They offer a unique combination of full coverage protection without impeding routine maintenance. These AltRider products are designed and made in the USA, and display a level of fit, finish, and build quality that exceeds that of any other brand I have seen, and yes, that includes those famous German names we all know. I did have a question as I went about this installation and am happy to report that I received a reply to my email within a day or so that actually answered my question, so it seems that customer support is good, as well. All in all, I am very happy to have these parts on my bike, and look forward to many years of good service from them. With products as nice as these, with all the little touches like including thread locking agent, anti-seize,

torx bits, clear detailed instructions with crisp photos and required tools lists, I expect that AltRider will grow to become a major player in the Adventure Riding field, and I say it is about time that there was a David to challenge the various Goliaths of the accessory market that we've all grown so used to.

A Happy GSW with its new AltRider Crash Bars and Skid Plate!

Author's Note: I make my living as a technical writer, creating mind-numbingly dry and boring software manuals for the financial services industry that are entirely devoid of humor or creativity. If more people read my manuals, insomnia would not exist! I write little reviews like this one purely for fun, as a kind of antidote for the writing I must do on a daily basis. I have no financial interest in any of the companies whose products I write about, nor am I on their payrolls. The information presented is my personal opinion, and mine alone. I hope you enjoyed it and found it informative! Farkle on, my friends!

See this review on my little web site here: http://home.comcast.net/~emoto1/AltRiderSkidPlateCrashBars.htm