barron_williams

Monza Blue 1974 R90/6

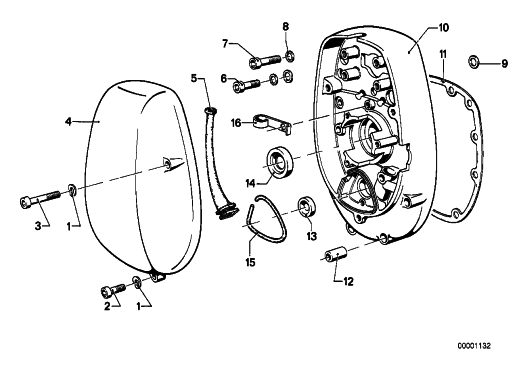

One of the things I always have trouble with is replacing the points/advance unit gasket.

I know you have to hold one end and pull it a bit to thin it out to fit into the channel. But, with the tension, it seems to pop out of the rounded section just as you are about half way down the next side.

Is there a particular gasket cement that works well?

Anybody have an great tricks for replacing this item?

I'm referring to #15

Barron

I know you have to hold one end and pull it a bit to thin it out to fit into the channel. But, with the tension, it seems to pop out of the rounded section just as you are about half way down the next side.

Is there a particular gasket cement that works well?

Anybody have an great tricks for replacing this item?

I'm referring to #15

Barron