AntonLargiader

Active member

Barrel shaped wear on spline teeth will only happen with simultaneous inverse barrel shaped wear on the clutch hub.

Not true. Look, I'm really not trying to pick on you but while I can theorize with the best of them, theory is only valid when it's applied in a relevant way. The facts don't support the way you've been theorizing.

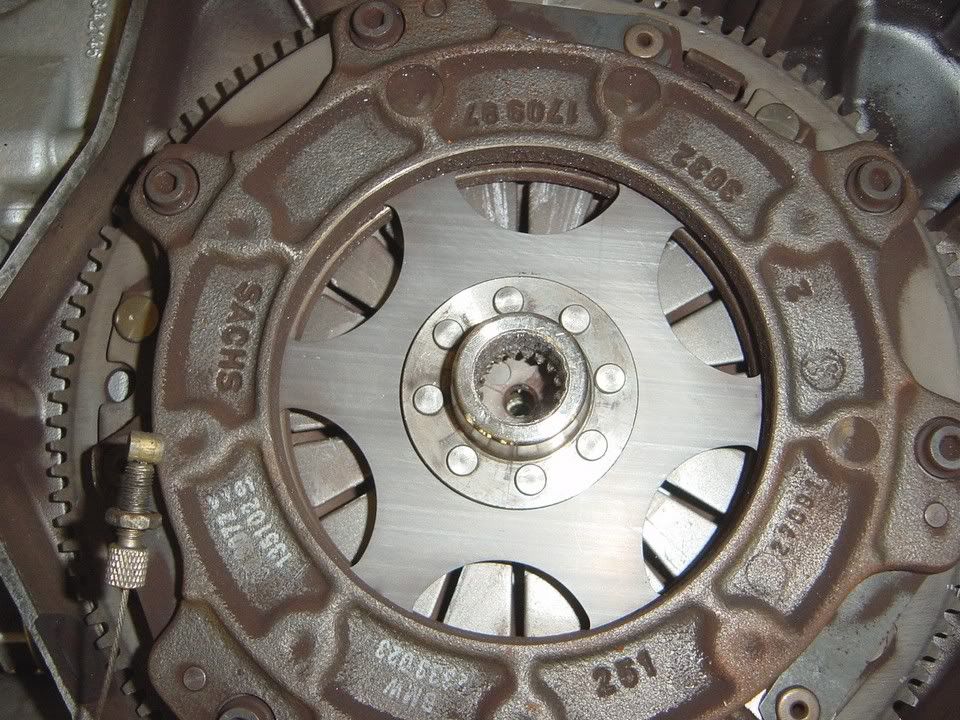

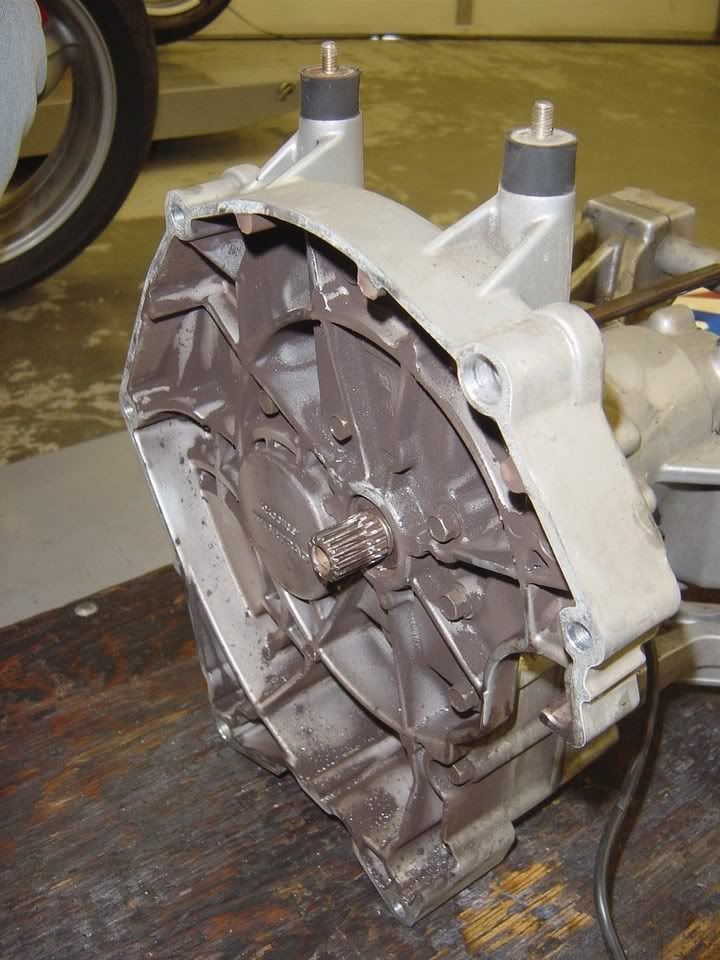

Looking at heavily worn 1150 clutch splines we can see the angled wear pattern. Let's say it's 5??. Does anyone - ANYONE - honestly think there is a 5?? misalignment between the engine and transmission, or a 5?? warp in the clutch carrier? Believe me, the former would have the bike going in circles and the latter wouldn't have room to turn between the engine and transmission.

Understanding that the 5?? comes from something else is critical.