2dflier

New member

My contention is that it never recenters. If there was an initial misalignment, that misalignment will reappear and the resulting shear force across the spline will be present every engine revolution. The spline shear force vector will be stationary, as the spline rotates. If I was to build a spline wear fatigue test system (my pre-retirement job) I would use a rotating spline set and radial misalignment control.

Again - it never recenters except for the trivial case where the clutch is disengaged.

I guess old threads will remain alive so long as people new to the problem try to understand what's happening and why, and how best to repair. This thread and post in particular is especially insightful.

I've got a couple of questions and observations and would appreciate some internet wisdom.

My case is an '04 RT @ 95K miles. It developed a neutral input rattle at about 70K and the last couple of hundred miles it was making some kind of grinding noise while going down the road. So out came the trans.

The clutch still has about 2mm of wear left but the splines are all but gone. So it was just a matter of time. I've had the bike since 62K but in the repair history - such that it is - or trans removal there's no indication the splines have ever been lubed.

Going into it my main question was whether or not I could just replace the friction disk or does the pressure plate and housing cover also need to be replaced. Having measured all three components it's pretty clear they need to be replaced as a set. The pressure plate is worn about 0.2mm more on the ID than the OD. The clutch housing about 0.4mm more.

My question is does anyone understand why the plates wear more on the ID and disk more on the OD? I can not come up with any reason why.

The offset between engine and trans is interesting. Including also TIR, the crank and trans input essentially rotate about fixed centers. The friction disk floats to accommodate any radial offset between the two. In a perfect world there's no radial offset or angular misalignment between the two and the forces acting on the splines and friction disk are related to torsional loads.

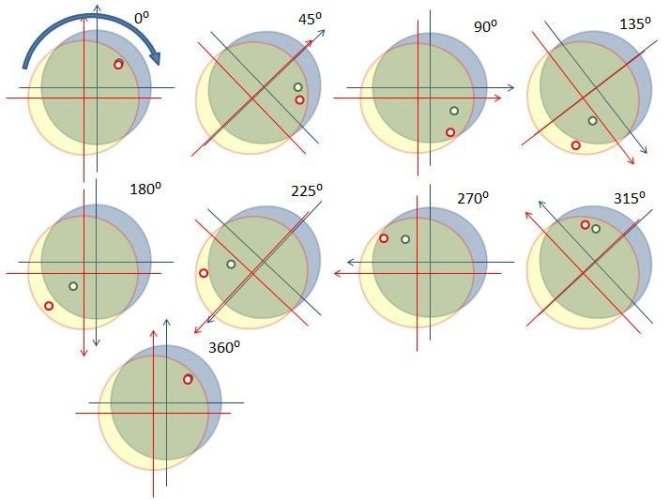

If I understand the real world correctly the radial offset results in a spline load radial vector in the opposite direction of the offset with a magnitude related to the normal force and coefficient of friction between disk and plates. The greater the radial offset the higher the wear rate. With each rotation the disk and plates move radially relative to each other twice the offset distance (max + radial distance at 0 degree rotation to offset, aligned at 90 deg rotation to offset, max - radial distance at 180 degree rotation from offset, aligned again at 270 degree rotation from offset, back to 0).

So with each crank rotation the disk and plates move twice the radial offset distance to each other. If wear is related to heat, then the greater the offset the more heat will be generated. Whether the offset is 0.1mm or 1.0 mm the disk and plates have to move twice the total distance per revolution. So the greater the offset the faster the average relative surface speed (and acceleration/peak surface speed) between the two to cover the total distance per rotation. Heat is related to surface sliding speed and friction.

So if all this is correct, the choice of friction material is also important. I assume Sachs matches the plate and disk material to optimize wear life. So what happens if you use a more aggressive friction material? Seems like you'd increase plate wear and spline radial spline forces - ie spline wear would also increase. For this reason I think I'll replace with the OEM disk unless someone knows better.

The thing I also wonder about is whether the total offset (radial plus TIR) can be estimated from the pressure plate and housing cover wear. The pressure plate looks to be about 1.0 mm larger diameter than the disk. In my case the pressure plate is worn to the edge. On the housing cover the heat zone is about the same diameter as the disk but the wear zone diameter is about 2 mm greater. Does this give some indication of the total radial relative motion?

So this is how I can makes sense of this. Right or wrong I don't know. Thoughts?

Last edited: