Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mid-South ride, eat, and meet

- Thread starter barryg

- Start date

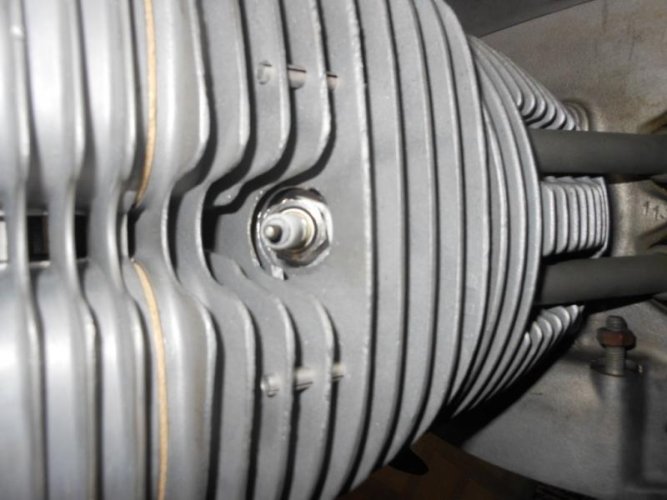

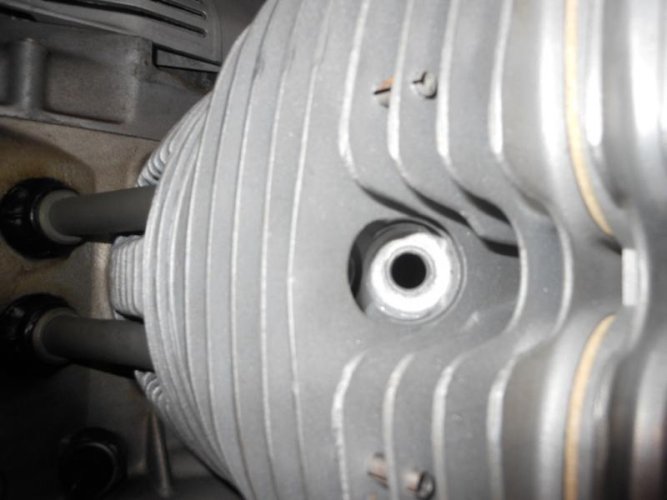

My nephew is long gone, and I'm loading these pics from instruction he gave me a few days ago. The last pic shows the lower taped hole for the 2nd plug. I timeserted the plug hole to give the threads a good threaded hole, so I will not have to worry about stripped threads on the added plug. I believe the timesert can be seen in the pic without the sparkplug installed.

CBB project

On this build I decided I wanted an old school look to mimic what a BMW rider would do back in the mid to late 70's to update his bike. I think dual plugging has a neat classic look. I grew up back in the day when all the shade tree mechanics were allways trying to hop up their cars/bikes on the cheap.

On this build I decided I wanted an old school look to mimic what a BMW rider would do back in the mid to late 70's to update his bike. I think dual plugging has a neat classic look. I grew up back in the day when all the shade tree mechanics were allways trying to hop up their cars/bikes on the cheap.

Years ago I built a jig/fixture to dual plug heads. The jig was mounted on an adjustable angle plate,which was mounted to a verticle up right milling machine, I believe it was a Bridgeport. Worked like a champ. Anyway, The heads got the 2nd plug. I then did my regular head jobs on the heads. New guides, ground the valves and cut the seats. Back cut the valves like I did on the race heads. Nice standard job, just like I did for all my customers.

This engine had been freshened up back in '90. It got the basic head job. When I had the heads off back then I checked the pistons and cylinders and it really needed new pistons, as it was just outside of tolerance. Didn't have the money. I honed the cylinders, decarbed the pistons and installed new rings. Buttoned it all back up and rode it hard for 30,000 more miles. During this rebuild, it got 1st over Kolbinsmitt pistons and rings. No it won't blow any R90S's off the road, but it'll run like a good R90/6 ought to.

Posting picture practice

Had this head sitting there, so I took a few pics for practice. This was off a '74 R90 I had bought as a parts bike. Nothin special here just a good basic head job. No dual pluggin, lookin at the valve I see I didn't even back cut the valve. I think this was a head I did as a display unit for showing head work. I think the heads on my CBB project was also used as a display for head work. It bothered some customers that they were dual plugged. So I learned carry a set of heads that were stock. I never tried to sell customers work they didn't need or want. Anyway, I'm just practicing picture posting.

Had this head sitting there, so I took a few pics for practice. This was off a '74 R90 I had bought as a parts bike. Nothin special here just a good basic head job. No dual pluggin, lookin at the valve I see I didn't even back cut the valve. I think this was a head I did as a display unit for showing head work. I think the heads on my CBB project was also used as a display for head work. It bothered some customers that they were dual plugged. So I learned carry a set of heads that were stock. I never tried to sell customers work they didn't need or want. Anyway, I'm just practicing picture posting.

Cool Look

The picture shows the standard airbox of a /6 next to the drilled airbox of my 90/6. Back when I was a kid I'd see guy's turn their car's top airbox cover upside down to let a little more air into the carb. They thought they were getting more hp and were in the know on engine performance. Back in the eighties when I bought my R90, I hung out in a guy's garage who built and serviced hi performance cars and bikes for his clientele. He had a real pristene '77 R100RS, and I noticed the holed airbox. I took my airbox off and went to get a drill bit. He stopped me, then reached in his tool box and handed me a step drill. In short work my 2 airbox covers had the appropiate hole pattern. Reinstalled the covers and stepped back and admired my 1st engine modification. He watch all this, laughted and proceeded to tell me I hadn't really gained anything. Didn't matter, it looked cool and sometimes a cool look trumps everthing.

The picture shows the standard airbox of a /6 next to the drilled airbox of my 90/6. Back when I was a kid I'd see guy's turn their car's top airbox cover upside down to let a little more air into the carb. They thought they were getting more hp and were in the know on engine performance. Back in the eighties when I bought my R90, I hung out in a guy's garage who built and serviced hi performance cars and bikes for his clientele. He had a real pristene '77 R100RS, and I noticed the holed airbox. I took my airbox off and went to get a drill bit. He stopped me, then reached in his tool box and handed me a step drill. In short work my 2 airbox covers had the appropiate hole pattern. Reinstalled the covers and stepped back and admired my 1st engine modification. He watch all this, laughted and proceeded to tell me I hadn't really gained anything. Didn't matter, it looked cool and sometimes a cool look trumps everthing.

There was a lot of work getin done at the hanger yesterday, and I missed most of it. Excellent demo on the valve adjustment of a hex head GS. Brad does a good job of explaining the little intricate details of the procedure for us pedrestrians. The hex head has advanced on from the oil head.

Excellent Tech Day

There was a lot of work getin done at the hanger yesterday, and I missed most of it. Excellent demo on the valve adjustment of a hex head GS. Brad does a good job of explaining the little intricate details of the procedure for us pedrestrians. The hex head has advanced on from the oil head. Also, it was the first day above freezing in over a month, good to have Mother Nature on our side for a change.

The hex head has advanced on from the oil head. Also, it was the first day above freezing in over a month, good to have Mother Nature on our side for a change.

There was a lot of work getin done at the hanger yesterday, and I missed most of it. Excellent demo on the valve adjustment of a hex head GS. Brad does a good job of explaining the little intricate details of the procedure for us pedrestrians.

The hex head has advanced on from the oil head. Also, it was the first day above freezing in over a month, good to have Mother Nature on our side for a change.

The hex head has advanced on from the oil head. Also, it was the first day above freezing in over a month, good to have Mother Nature on our side for a change.