W

waehrik

Guest

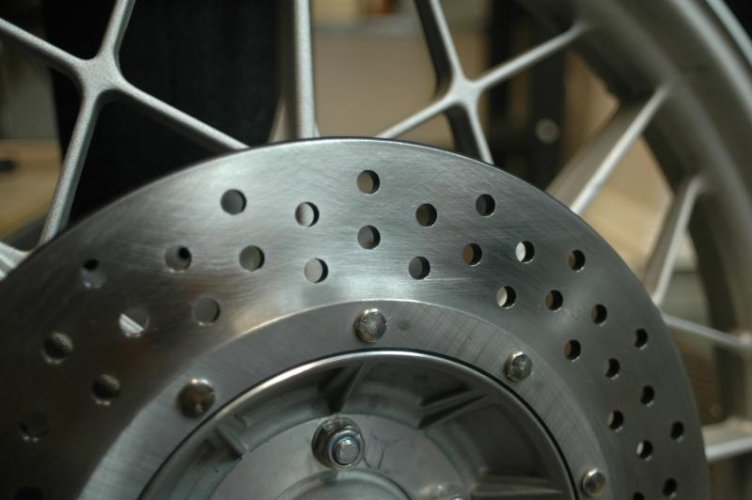

I have a 75 R90/6 on which the single drilled stainless rotor is pulsing when using it and I measured the disk to be warped by about 0.005". I can't find a minimum thickness spec on the rotor itself though, the aluminum had a nice white corroded finish that even when removed has obscured any markings that were once present on the hub. The rotor now measures 5.3 mm.

Does anyone know what the minimum thickness spec is of these drilled stainless rotors?

Thanks!

Does anyone know what the minimum thickness spec is of these drilled stainless rotors?

Thanks!

Last edited:

It's been pretty boring around here lately at Airhead Central anyway.

It's been pretty boring around here lately at Airhead Central anyway.  - but I can usually hang in there with the engineers and physicists - for a while.

- but I can usually hang in there with the engineers and physicists - for a while.