30064

Mike V. #30064

I'm getting ready to do a complete (Fr & Rr) wheel bearing and seal replacememnt on my 78 R100/7 with snowflakes. A quick search found no pictorial links unless I missed it. Does anyone have a photo/tutorial series of the procedure outside of Bum and Duane's instruction?

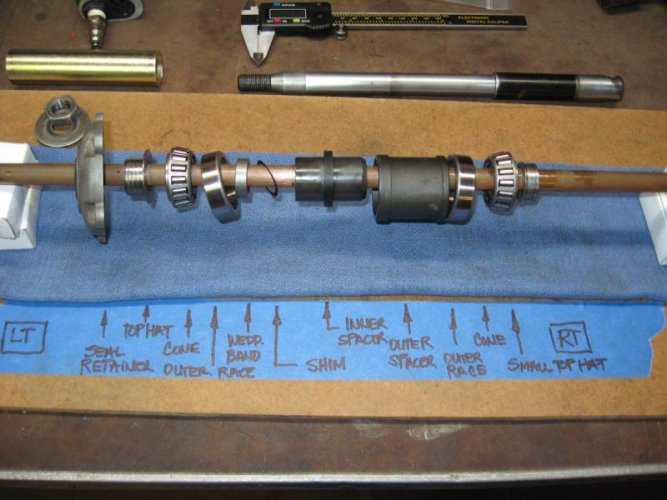

Edit 11-09-14: I wanted to add a global edit to the following pages of this thread in regards to the 0.05mm shims shown and mentioned. My personal procedure has changed since this thread was created. I no longer use the 0.05mm shims, my final preload determination is done with WEDDING BAND ONLY. Your decision is your own to use or not use them. My reason for omitting these small thin spacers is my concern for another wrench entering the bearing stack not knowing how many or misplacing - loosing them. If the preload is near the light or heavy limits 0.05mm can make a difference.

If you choose to use the 0.05mm shims I would recommend making notes of the precise number of shims in your records so they can be retrieved during future servicing.

Edit 11-09-14: I wanted to add a global edit to the following pages of this thread in regards to the 0.05mm shims shown and mentioned. My personal procedure has changed since this thread was created. I no longer use the 0.05mm shims, my final preload determination is done with WEDDING BAND ONLY. Your decision is your own to use or not use them. My reason for omitting these small thin spacers is my concern for another wrench entering the bearing stack not knowing how many or misplacing - loosing them. If the preload is near the light or heavy limits 0.05mm can make a difference.

If you choose to use the 0.05mm shims I would recommend making notes of the precise number of shims in your records so they can be retrieved during future servicing.

Last edited: