R

RSPENNACHIO

Guest

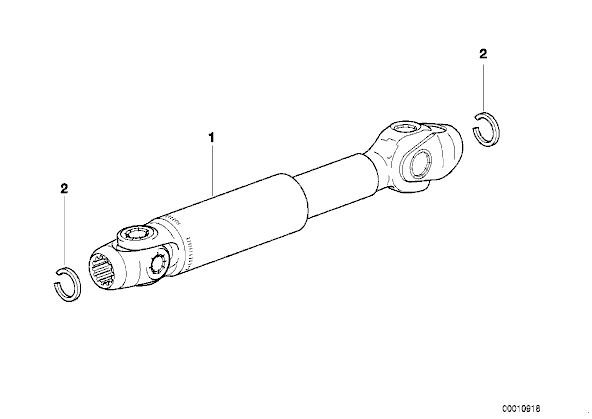

Does anyone know who manufactures the 2007 to present "R" bike driveshaft? Or does anyone have technical specs on it?

U joint size

length

plunge

runout

balance

DOM / HSLA steel?

Spline profle for each socket yoke

U joint size

length

plunge

runout

balance

DOM / HSLA steel?

Spline profle for each socket yoke

.......................

.......................