My engine management light came on after sitting for awhile, and the bike started running a bit rough, although not in limp mode and I could still drive it.

I did some diagnostics with my GS 911 and came up with the following error codes:

OX21FD32 Camshaft Sensor input signal number and position of edges implausible

OX21FD31 Camshaft Sensor input signal no single edge detected, input level low

That being discovered, I bought and installed a new battery, since the old was about 7 years old, thinking this could have contributed to the error code.

Unfortunately, this did not solve the problem.

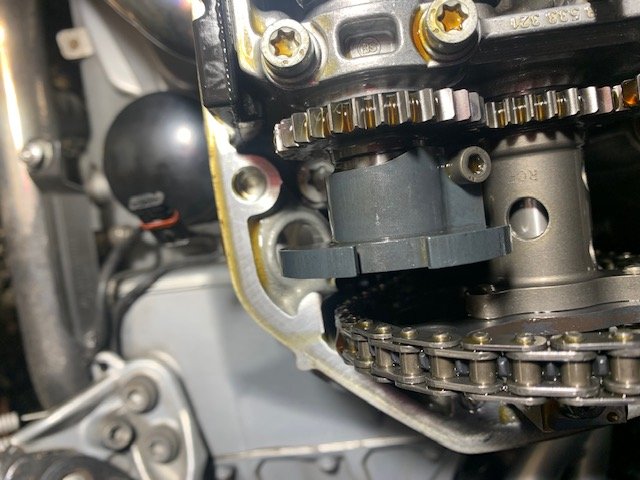

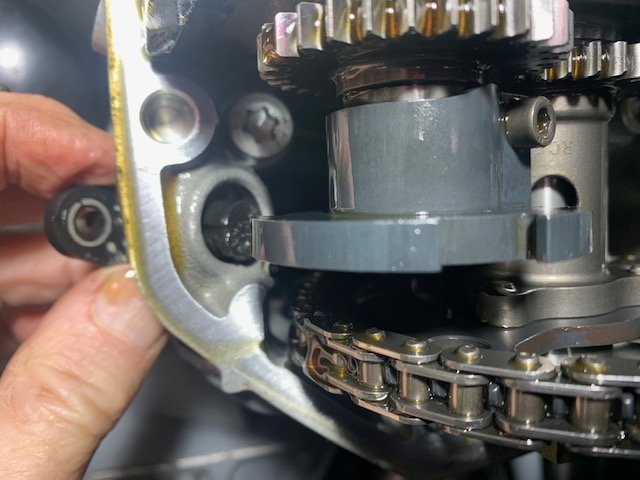

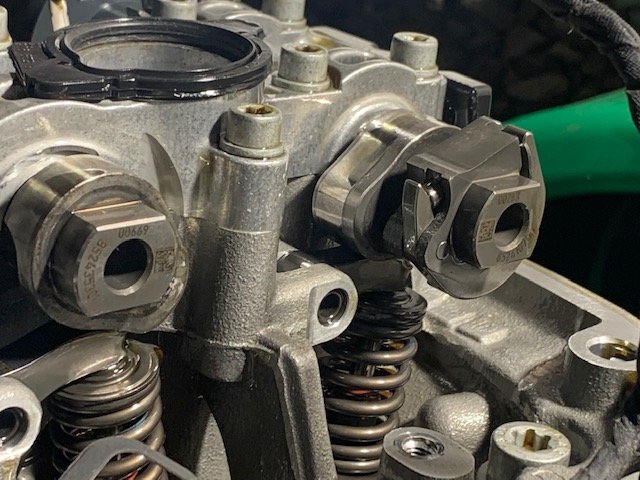

So I removed the cam sensor and engine side cover to expose the camshaft and I noticed some powdered debris on the top of the cam sensor. This contacts the plastic reluctor attached to the camshaft. I am thinking either the sensor is bad, and or the reluctor is worn somewhat, as it appears to be made of plastic.

Has anyone else on the forum experienced this type of failure and do you think I should order both parts and replace them? Also, are there any adjustments to be made with the reluctor as it is installed onto the camshaft?

I did some diagnostics with my GS 911 and came up with the following error codes:

OX21FD32 Camshaft Sensor input signal number and position of edges implausible

OX21FD31 Camshaft Sensor input signal no single edge detected, input level low

That being discovered, I bought and installed a new battery, since the old was about 7 years old, thinking this could have contributed to the error code.

Unfortunately, this did not solve the problem.

So I removed the cam sensor and engine side cover to expose the camshaft and I noticed some powdered debris on the top of the cam sensor. This contacts the plastic reluctor attached to the camshaft. I am thinking either the sensor is bad, and or the reluctor is worn somewhat, as it appears to be made of plastic.

Has anyone else on the forum experienced this type of failure and do you think I should order both parts and replace them? Also, are there any adjustments to be made with the reluctor as it is installed onto the camshaft?