evillerich

New member

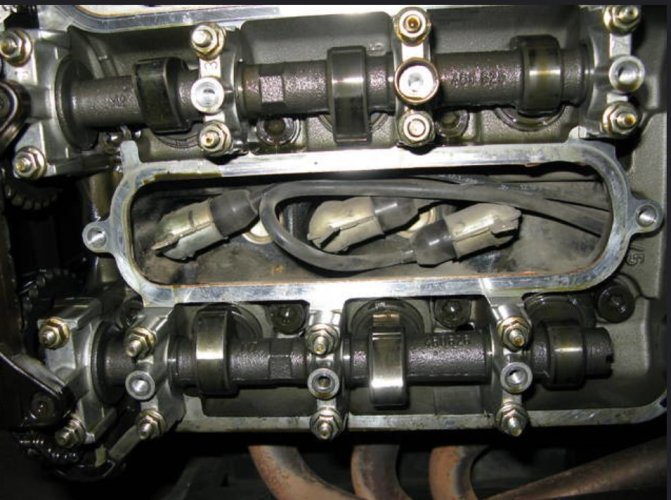

I've finally gotten around to taking off the valve cover of my '87 K75S. Has a bit over 30k miles on it. A previous owner had painted the valve cover, so it at least came off then. But I spent a lot of time removing RTV sealant from the two channels that contain the valve cover rubber seals. I'll be replacing the rubber seals for the cover, plus the ones on the bolts. Naturally I'll use a gasket sealer at the four joint areas at the corners plus on the new half-moon inserts.

Anyway, I did my valve check and everything came out within spec. But at the low-end of spec. For example, my 0.15mm feeler goes in with just a slight resistance (so does my 0.152) on the intake valves. But my 0.178mm gauge won't go at all. Similar story on the exhaust side but with 0.25mm as the tight end of the range. Given that a wider gaps is generally desirable, I'm wondering if it's worth reshimming the valves.

While I don't ride this bike as my primary, I do want to try to "do it right" and would like to increase my annual miles on it (it's been in a constant state of some restoration since I owned it). I also imagine a future owner may appreciate it, too.

Any advice on whether it's worth it? Or just close it up and wait for the next valve check period? One side of me prefers to just close it up.

Thanks,

Eville Rich

'87 K75S

Anyway, I did my valve check and everything came out within spec. But at the low-end of spec. For example, my 0.15mm feeler goes in with just a slight resistance (so does my 0.152) on the intake valves. But my 0.178mm gauge won't go at all. Similar story on the exhaust side but with 0.25mm as the tight end of the range. Given that a wider gaps is generally desirable, I'm wondering if it's worth reshimming the valves.

While I don't ride this bike as my primary, I do want to try to "do it right" and would like to increase my annual miles on it (it's been in a constant state of some restoration since I owned it). I also imagine a future owner may appreciate it, too.

Any advice on whether it's worth it? Or just close it up and wait for the next valve check period? One side of me prefers to just close it up.

Thanks,

Eville Rich

'87 K75S

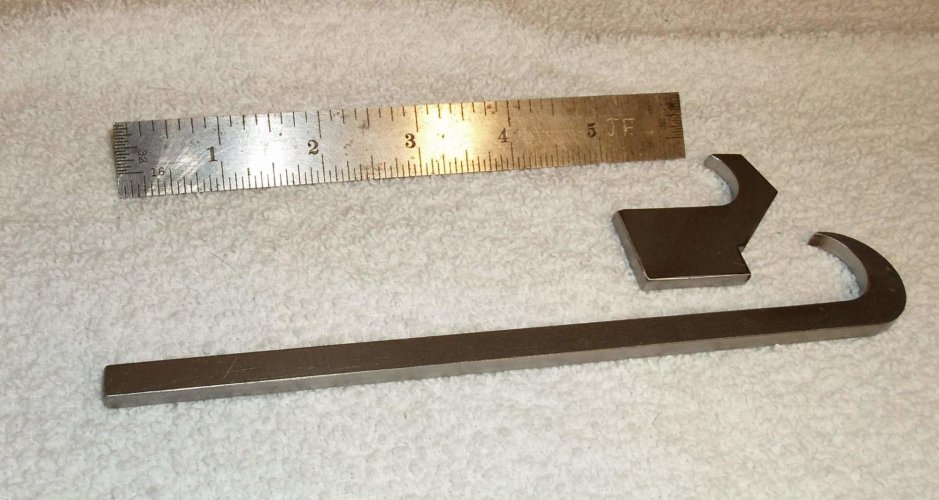

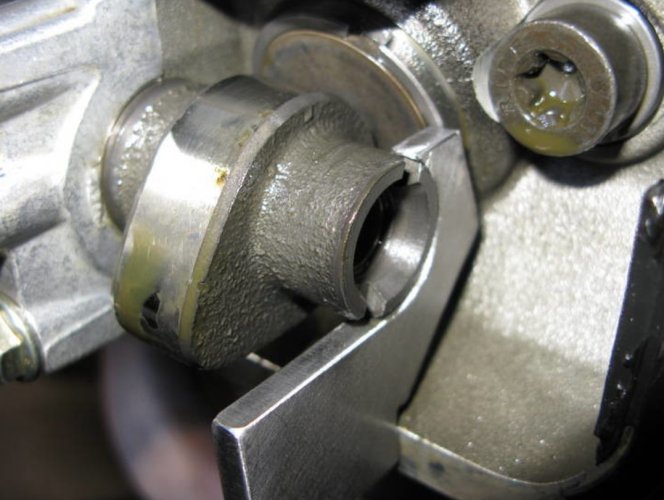

What about this tool facilitates the shim changing? Thanks.

What about this tool facilitates the shim changing? Thanks.