I am in the middle a top end and cylinder base overhaul of my R90/6. While looking up specs to check for piston ring wear limits (as in gap between the rings and the ring groove in the piston) I have come up with a bit of a surprise. I have several sources which I have crossed checked for the specs of ring thickness and piston groove width and they all agree. However my pistons and the corresponding rings are all narrower. I can find no reference to this online. My pistons do appear to be stock and OEM with the standard stamping on the crown showing the diameter (89.975), the marking VORN (Front) and the arrow showing facing forward.

Were the pistons made with narrower grooves at one time? My machine type number is 2476. Can anyone help me with this situation as I'm not presently sure how to order the correct ring kits for my machine.

I do see three different ring sets available on a BMW microfiche but since there are no details, I assume these for different bore over sizes. Maybe one of them is for the shallow ring set but there are no details and I thought I would check with the community first.

Thank you.

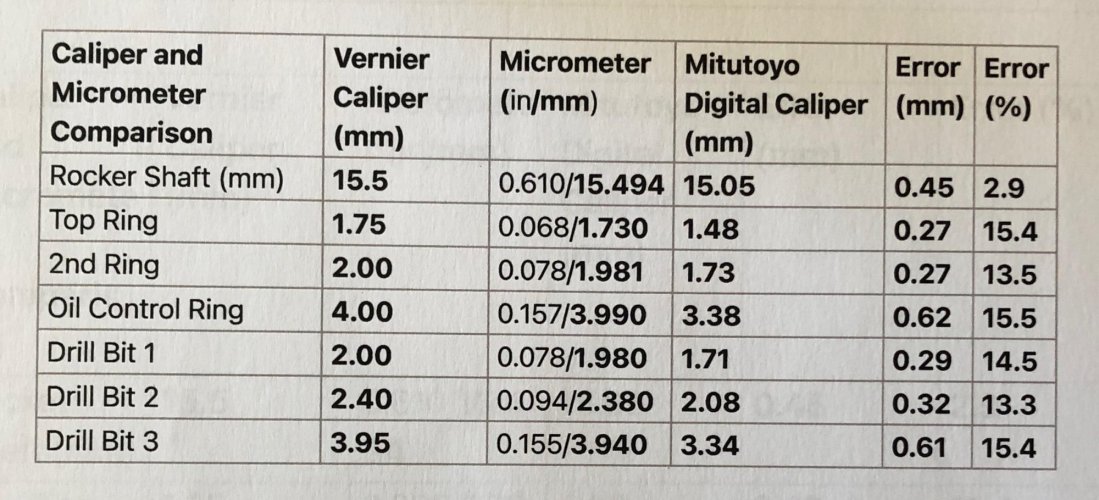

Dimensions in question are shown below. Hope it retains its formatting. Not too sure how to do a table in a post!:

....................Ring Thickness widely published.........Actual Ring Thickness........Groove in piston actual

Top................1.75 mm (0.068")........................1.47 (0.058)........................1.63 (0.064)

Middle............2.00 (0.078)...............................1.72 ((0.068).......................1.76 (0.069)

Oil Control.......4.00 (0.156)...............................3.38 (0.133)........................3.42 (0.135)

Were the pistons made with narrower grooves at one time? My machine type number is 2476. Can anyone help me with this situation as I'm not presently sure how to order the correct ring kits for my machine.

I do see three different ring sets available on a BMW microfiche but since there are no details, I assume these for different bore over sizes. Maybe one of them is for the shallow ring set but there are no details and I thought I would check with the community first.

Thank you.

Dimensions in question are shown below. Hope it retains its formatting. Not too sure how to do a table in a post!:

....................Ring Thickness widely published.........Actual Ring Thickness........Groove in piston actual

Top................1.75 mm (0.068")........................1.47 (0.058)........................1.63 (0.064)

Middle............2.00 (0.078)...............................1.72 ((0.068).......................1.76 (0.069)

Oil Control.......4.00 (0.156)...............................3.38 (0.133)........................3.42 (0.135)

Last edited:

... Take comfort in knowing that you're not the only one who can make a mistake.

... Take comfort in knowing that you're not the only one who can make a mistake.  Thanks for the heads-up and resolution.

Thanks for the heads-up and resolution.