davidanderson327

New member

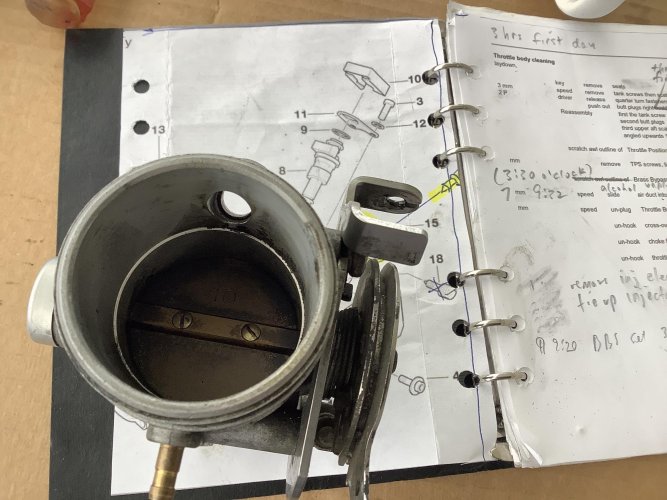

1994 R1100RSL. Do throttle-body cleaners with acetone also dissolve the TPS plastic insides?

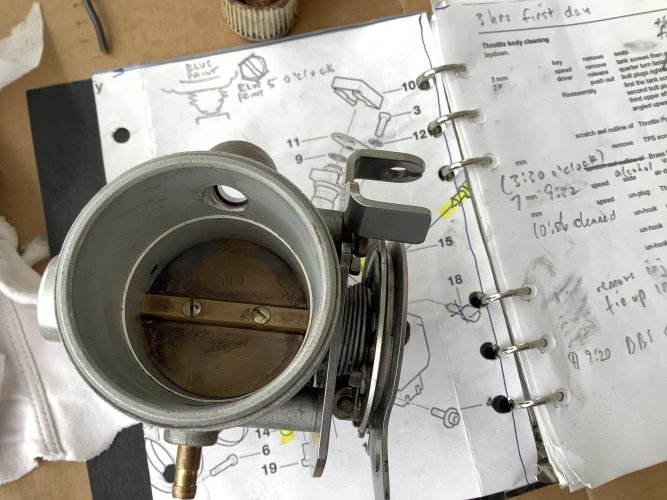

While replacing my wet head gaskets, I see my throttle-bodies' venturis are stained with carbon. The auto parts store brands have acetone and toluene to dissolve that varnish. A YouTub video showed liberally rinsing the venturi with spray can cleaner, scrubbing with a brush along the butterfly for a good seal.

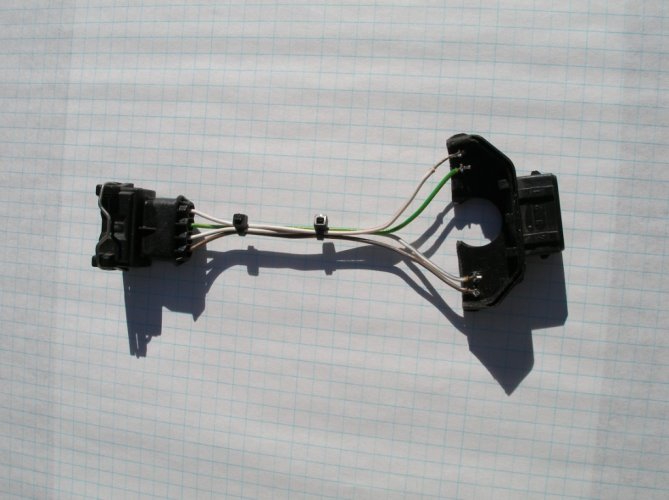

Will getting the Throttle Position Sensor pivot there inside the venturi, getting it wet with these powerful solvents, also dissolve the plastic inside the TPS mechanism?

Have you rinsed your venturi, wetting the TPS pivot, without disturbing the TPS?

David Anderson 228147

Escondido CA

While replacing my wet head gaskets, I see my throttle-bodies' venturis are stained with carbon. The auto parts store brands have acetone and toluene to dissolve that varnish. A YouTub video showed liberally rinsing the venturi with spray can cleaner, scrubbing with a brush along the butterfly for a good seal.

Will getting the Throttle Position Sensor pivot there inside the venturi, getting it wet with these powerful solvents, also dissolve the plastic inside the TPS mechanism?

Have you rinsed your venturi, wetting the TPS pivot, without disturbing the TPS?

David Anderson 228147

Escondido CA