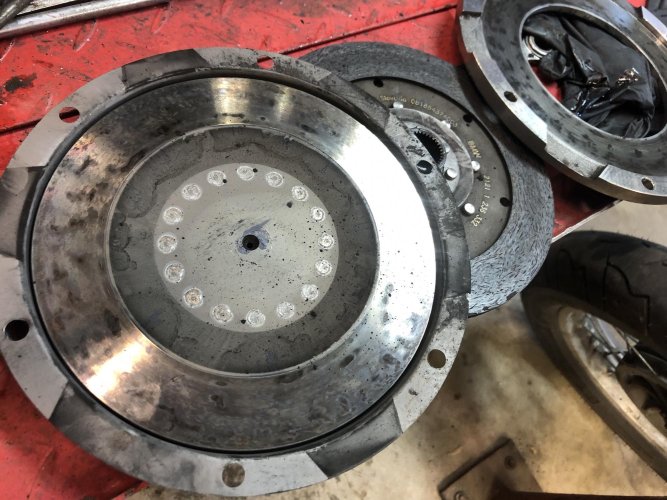

The bike: '76 R90/6, Siebenrock big bore kit, dual plug conversion, Alpha ignition, R100/7 final drive (more top end, lower rpms at highway speed). The bike runs GREAT! However. Last summer I notice some clutch slipping during hard acceleration so I decided to replace pressure plate, friction disc and pressure ring. It had the "heavy duty" diaphragm spring already installed from a couple of years ago.

Today while pulling a long hill against the wind at about 85mph....it started to slip. I lightened up on my throttle hand and it returned to normal. I put about 100 more miles on it today. No unnecessary hard acceleration. I also passed a couple of cars going 80-85mph, no more hint of slippage.

I am going to go back in there and replace the diaphragm spring, the one component I didn't change last summer. The old spring is about 10 years old.

However, I would like to ensure that whatever I do will solve the problem. I just read the Snobum article about placing "a .035"-.065" hard steel donut ring shim between the flywheel and the spring base." This would effectively "tighten" up the spring against the pressure plate. What is everyone's thoughts on this? Also let me re-phrase the article: The flywheel has an area that the diaphragm spring resides in...then comes the pressure plate. He's talking about taking hard shim stock and making a ring that the comes between the spring and the flywheel...am I envisioning this right? This would increase the clutch pull slightly but it's worth it not to have high speed slippage.

Your thoughts?

Today while pulling a long hill against the wind at about 85mph....it started to slip. I lightened up on my throttle hand and it returned to normal. I put about 100 more miles on it today. No unnecessary hard acceleration. I also passed a couple of cars going 80-85mph, no more hint of slippage.

I am going to go back in there and replace the diaphragm spring, the one component I didn't change last summer. The old spring is about 10 years old.

However, I would like to ensure that whatever I do will solve the problem. I just read the Snobum article about placing "a .035"-.065" hard steel donut ring shim between the flywheel and the spring base." This would effectively "tighten" up the spring against the pressure plate. What is everyone's thoughts on this? Also let me re-phrase the article: The flywheel has an area that the diaphragm spring resides in...then comes the pressure plate. He's talking about taking hard shim stock and making a ring that the comes between the spring and the flywheel...am I envisioning this right? This would increase the clutch pull slightly but it's worth it not to have high speed slippage.

Your thoughts?