senseamidmadness

Neglected Bike Adopter

I'm quite excited and wanted to share with you folks. After years of Internet videos and reading I have finally taken the first big step into becoming a hobby machinist, and bought a small green drehmaschine!

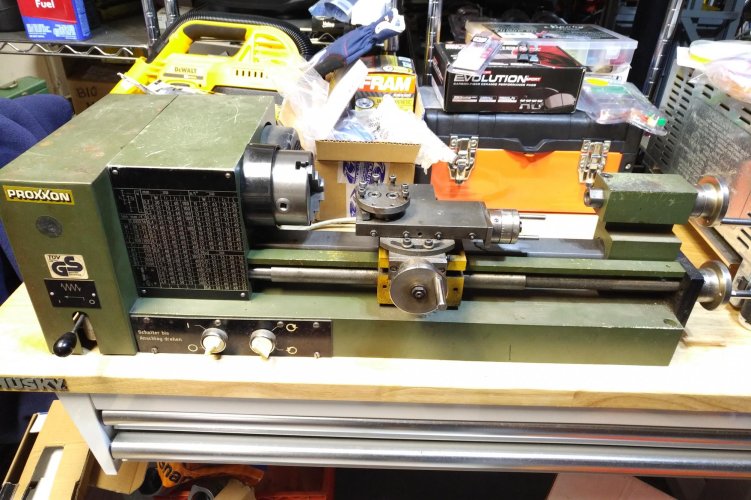

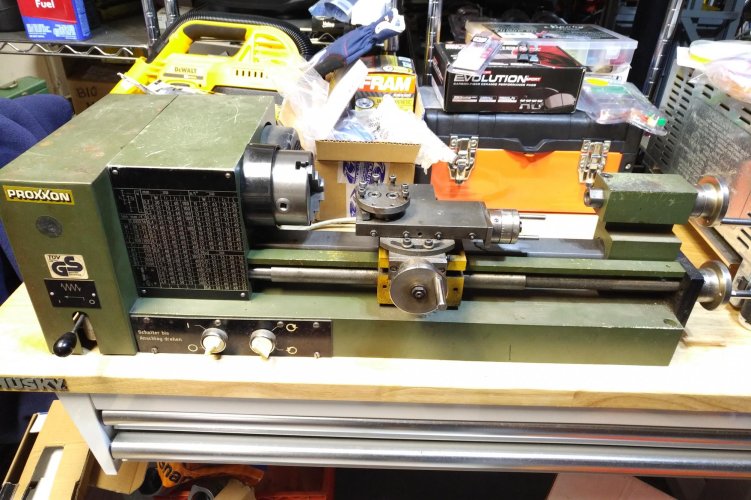

It is a Proxxon SD300, approximately a 5x12 mini lathe, and was made in the Republic of West Germany in 1982. Other than being very dirty and unused for years it seems to be in excellent shape. The bed looks pristine and most of the paint is perfectly intact, and with the locking screws backed out all four hand wheels move very smoothly.

The biggest reason I sprang for this one is that it's entirely metric. My brain doesn't think in inches, and finding metric hobby lathes here in the US can be rather difficult. This is the only one I've seen in months of looking at local classifieds. It took about 9 hours of roundtrip driving in one day to get it from west Georgia and bring it home.

It works, and came with most of the original accessories, but it is missing a few things. I don't have any of the original wrenches or screwdrivers or the manual, and it's missing the 50mm vise that it came with as part of a horizontal milling conversion kit. Fortunately I do have the angle plate for that and can probably find or convert a suitable tiny vise.

The biggest hassle is that it's missing most of its power feed and threading change gears. Out of the original 11 it came with, these four were the only ones stuck to the machine, and they don't fit together in a way that turns the lead screw.

Original replacement gears are a pain to get hold of; I'd have to order used ones from England for something like $30 each (not gonna happen for plastic gears), try to see if the only importer of the modern clone of this machine has them in stock, buy off-the-shelf gears and modify them to fit, or I can try to get some 3D printed. The last is the most likely as I have a couple buddies who have 3D printers and these are fairly simple gears.

I don't have any tooling other than the 1 HSS cutter it came with, and as anybody who owns a lathe knows that's the biggest cost hill to climb. Getting hold of working accessories for a lathe this old and small isn't the easiest, but there's a company in California that imports the modern Czech clones of this machine under the brand name Prazi. I'll have to order things like an independent four-jaw chuck from them and other things like a reasonably priced quick change tool post will have to come from England.

The first step before I go buying a ton of other things though will be to completely take the machine apart and get it cleaned, oiled, and adjusted. I have a suspicion that the spindle bearings, which are grease-lubricated, haven't been repacked since they left the factory 40 years ago.

After that, I have enough existing tooling to start making simple things like tubular spacers and bushings for the motorcycles. Maybe one day soon I'll be able to make some useful parts for other folks in the MOA that need them.

It is a Proxxon SD300, approximately a 5x12 mini lathe, and was made in the Republic of West Germany in 1982. Other than being very dirty and unused for years it seems to be in excellent shape. The bed looks pristine and most of the paint is perfectly intact, and with the locking screws backed out all four hand wheels move very smoothly.

The biggest reason I sprang for this one is that it's entirely metric. My brain doesn't think in inches, and finding metric hobby lathes here in the US can be rather difficult. This is the only one I've seen in months of looking at local classifieds. It took about 9 hours of roundtrip driving in one day to get it from west Georgia and bring it home.

It works, and came with most of the original accessories, but it is missing a few things. I don't have any of the original wrenches or screwdrivers or the manual, and it's missing the 50mm vise that it came with as part of a horizontal milling conversion kit. Fortunately I do have the angle plate for that and can probably find or convert a suitable tiny vise.

The biggest hassle is that it's missing most of its power feed and threading change gears. Out of the original 11 it came with, these four were the only ones stuck to the machine, and they don't fit together in a way that turns the lead screw.

Original replacement gears are a pain to get hold of; I'd have to order used ones from England for something like $30 each (not gonna happen for plastic gears), try to see if the only importer of the modern clone of this machine has them in stock, buy off-the-shelf gears and modify them to fit, or I can try to get some 3D printed. The last is the most likely as I have a couple buddies who have 3D printers and these are fairly simple gears.

I don't have any tooling other than the 1 HSS cutter it came with, and as anybody who owns a lathe knows that's the biggest cost hill to climb. Getting hold of working accessories for a lathe this old and small isn't the easiest, but there's a company in California that imports the modern Czech clones of this machine under the brand name Prazi. I'll have to order things like an independent four-jaw chuck from them and other things like a reasonably priced quick change tool post will have to come from England.

The first step before I go buying a ton of other things though will be to completely take the machine apart and get it cleaned, oiled, and adjusted. I have a suspicion that the spindle bearings, which are grease-lubricated, haven't been repacked since they left the factory 40 years ago.

After that, I have enough existing tooling to start making simple things like tubular spacers and bushings for the motorcycles. Maybe one day soon I'll be able to make some useful parts for other folks in the MOA that need them.