Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tiny metal flakes on the drain plug -- should I be worried about my transmission?

- Thread starter senseamidmadness

- Start date

senseamidmadness

Neglected Bike Adopter

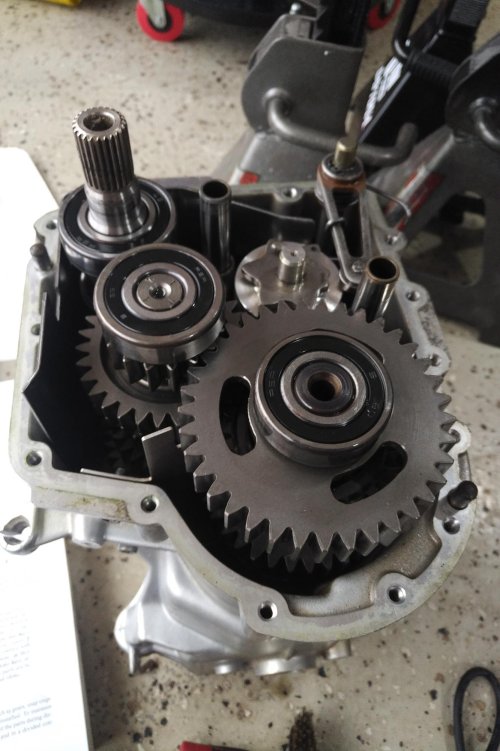

Finally, an update! After much procrastination and slowly ordering parts over the months, I finally got around to working on my transmission. I've attached pictures from various points in the process. I wish I had gotten a few more, especially of the input shaft before, during, and after the work on it specifically. Unfortunately I have none of those and I really should have taken some.

It was done over 3 days at a buddy's shop, at a faster pace than I usually work. Took about 15 hours of total labor including the parts where I was extra careful. First time and all that. Wasn't so bad, especially once I was actually able to get to the transmission. I found the internal work to be fairly straightforward. My buddy wasn't so confident; he said "are you sure you can put all that stuff back where you found it?" when I was pulling the shift forks out.

Despite his doubts, it's now running and riding again!

I ended up going with an NSK 6304VV non-contact-sealed bearing to replace the worn one on the input shaft, as I was able to get a new-old-stock pair for a good price. I had a complete M94 input shaft on hand just in case the wear had damaged the original, but ended up only needing the 20-tooth gear from it.

You can see a comparison between the original bearing and the new one in the pictures, with the worn input shaft gear and the used replacement next to them. The worn bearing had more play in it and definitely turned less smoothly than the other transmission bearings. Thankfully the wear wasn't nearly as advanced as some other documented rebuilds I saw. It had only damaged the gear and the bearing; when I got them pulled off there was just a bit of heat discoloration on the original input shaft, but all the diameters were right and there was no visible or tangible mechanical damage. Everything was still perfectly smooth and the replacement gear and bearing went on without fuss.

I also replaced the seals on both the input and output shafts by marking the original seal depths on an impact socket and driving the new ones in to the depth of the mark.

The only annoying part of the transmission work was when it came time to remove and replace the wave washer, which I did in an effort to prevent this problem from happening again. I found a few threads on the BMW Sport Touring and Uk GSer websites suggesting that its weak spring force allows these two parts to smack into each other repeatedly and violently when transmission load changes, and that certainly seems to be exactly what happened to mine -- you can even see in the pictures where the oil grooves in the gear have worn lumps into the bearing from this whacking motion. I ordered a new-old-stock flat steel washer, 28mm x 44mm x 3mm, as BMW part 23211340794, to replace the wave washer. Installing it requires that the adjacent part be modified, as it has a lip that works as a centering seat for the wave washer. My buddy did not have any of the right tools for this, so I had to do the slow thing and use a rotary sander, some hand sanding, and a small sanding drum on a Dremel to grind down the lip and get the part as flat as possible. Thankfully the new flat washer is quite wide so there was a decent margin for error and my hand work was good enough. Had I been near my lathe, I would have made a new washer instead of buying one and it would've been much easier to cut the spring seat off of that other part.

I used Yamabond 4 to seal the transmission back up, which is the first time I've ever used the stuff. Spreading it around felt like decorating a cake!

I was also able to get several other tasks done that I wanted to do -- I removed, cleaned, and re-torqued the swingarm bearing pins, inspected and greased my Paralever pivot bearings, lubricated the input shaft splines and all the driveshaft splines, got some grime cleaned out of hard-to-reach places, replaced my airbox (due to a mistake I made during service earlier this year), and overall got a good idea of how all the internal stuff fits together.

I filled the transmission with Bel-Ray GearSaver 85W-140 conventional, as I was able to get a couple quarts of the stuff for cheap and wanted to experiment.

The overall result? The bike runs just as well as it ever has, and the transmission is slightly, but noticeably, improved. Shifts are a bit smoother, the overall sound is a bit quieter with less whining on acceleration and deceleration (probably because of that bearing starting to wear out), and it no longer sounds like a gremlin with a hammer is trying to escape my transmission when I shift from 2nd to 1st. I ride with earplugs and a full-face helmet on and I noticed no difference regarding the transmission noise level in neutral.

I'm not sure how much of this is due to the heavier gear oil, but the biggest improvement is to my peace of mind knowing that my transmission isn't beating itself up inside.

It was done over 3 days at a buddy's shop, at a faster pace than I usually work. Took about 15 hours of total labor including the parts where I was extra careful. First time and all that. Wasn't so bad, especially once I was actually able to get to the transmission. I found the internal work to be fairly straightforward. My buddy wasn't so confident; he said "are you sure you can put all that stuff back where you found it?" when I was pulling the shift forks out.

Despite his doubts, it's now running and riding again!

I ended up going with an NSK 6304VV non-contact-sealed bearing to replace the worn one on the input shaft, as I was able to get a new-old-stock pair for a good price. I had a complete M94 input shaft on hand just in case the wear had damaged the original, but ended up only needing the 20-tooth gear from it.

You can see a comparison between the original bearing and the new one in the pictures, with the worn input shaft gear and the used replacement next to them. The worn bearing had more play in it and definitely turned less smoothly than the other transmission bearings. Thankfully the wear wasn't nearly as advanced as some other documented rebuilds I saw. It had only damaged the gear and the bearing; when I got them pulled off there was just a bit of heat discoloration on the original input shaft, but all the diameters were right and there was no visible or tangible mechanical damage. Everything was still perfectly smooth and the replacement gear and bearing went on without fuss.

I also replaced the seals on both the input and output shafts by marking the original seal depths on an impact socket and driving the new ones in to the depth of the mark.

The only annoying part of the transmission work was when it came time to remove and replace the wave washer, which I did in an effort to prevent this problem from happening again. I found a few threads on the BMW Sport Touring and Uk GSer websites suggesting that its weak spring force allows these two parts to smack into each other repeatedly and violently when transmission load changes, and that certainly seems to be exactly what happened to mine -- you can even see in the pictures where the oil grooves in the gear have worn lumps into the bearing from this whacking motion. I ordered a new-old-stock flat steel washer, 28mm x 44mm x 3mm, as BMW part 23211340794, to replace the wave washer. Installing it requires that the adjacent part be modified, as it has a lip that works as a centering seat for the wave washer. My buddy did not have any of the right tools for this, so I had to do the slow thing and use a rotary sander, some hand sanding, and a small sanding drum on a Dremel to grind down the lip and get the part as flat as possible. Thankfully the new flat washer is quite wide so there was a decent margin for error and my hand work was good enough. Had I been near my lathe, I would have made a new washer instead of buying one and it would've been much easier to cut the spring seat off of that other part.

I used Yamabond 4 to seal the transmission back up, which is the first time I've ever used the stuff. Spreading it around felt like decorating a cake!

I was also able to get several other tasks done that I wanted to do -- I removed, cleaned, and re-torqued the swingarm bearing pins, inspected and greased my Paralever pivot bearings, lubricated the input shaft splines and all the driveshaft splines, got some grime cleaned out of hard-to-reach places, replaced my airbox (due to a mistake I made during service earlier this year), and overall got a good idea of how all the internal stuff fits together.

I filled the transmission with Bel-Ray GearSaver 85W-140 conventional, as I was able to get a couple quarts of the stuff for cheap and wanted to experiment.

The overall result? The bike runs just as well as it ever has, and the transmission is slightly, but noticeably, improved. Shifts are a bit smoother, the overall sound is a bit quieter with less whining on acceleration and deceleration (probably because of that bearing starting to wear out), and it no longer sounds like a gremlin with a hammer is trying to escape my transmission when I shift from 2nd to 1st. I ride with earplugs and a full-face helmet on and I noticed no difference regarding the transmission noise level in neutral.

I'm not sure how much of this is due to the heavier gear oil, but the biggest improvement is to my peace of mind knowing that my transmission isn't beating itself up inside.

Attachments

-

IMG_20220811_1104555.jpg471 KB · Views: 252

IMG_20220811_1104555.jpg471 KB · Views: 252 -

IMG_20220810_1659306.jpg303.8 KB · Views: 252

IMG_20220810_1659306.jpg303.8 KB · Views: 252 -

IMG_20220810_1412026.jpg276.2 KB · Views: 252

IMG_20220810_1412026.jpg276.2 KB · Views: 252 -

IMG_20220810_1411576.jpg243.7 KB · Views: 257

IMG_20220810_1411576.jpg243.7 KB · Views: 257 -

IMG_20220810_1411527.jpg309.3 KB · Views: 254

IMG_20220810_1411527.jpg309.3 KB · Views: 254 -

IMG_20220810_0109438.jpg331.9 KB · Views: 255

IMG_20220810_0109438.jpg331.9 KB · Views: 255 -

IMG_20220810_0056141.jpg414.2 KB · Views: 256

IMG_20220810_0056141.jpg414.2 KB · Views: 256 -

IMG_20220810_0055017.jpg350.5 KB · Views: 257

IMG_20220810_0055017.jpg350.5 KB · Views: 257 -

IMG_20220810_0054482.jpg211.2 KB · Views: 264

IMG_20220810_0054482.jpg211.2 KB · Views: 264 -

IMG_20220809_1837178.jpg371 KB · Views: 255

IMG_20220809_1837178.jpg371 KB · Views: 255 -

IMG_20220809_1837042.jpg298.7 KB · Views: 255

IMG_20220809_1837042.jpg298.7 KB · Views: 255

mikegalbicka

Back in the saddle again

Well done. Enjoy the peace of mind you earned.

senseamidmadness

Neglected Bike Adopter

I'm thinking about opening up the transmission again -- I forgot to replace the oil seal at the clutch arm, as I was in a bit of a hurry and it wasn't obvious where it was just from looking. D'oh! Should have reviewed the official service manual again before starting.

If I'm going to crack it open again, though, I'll re-shim all the transmission shafts properly (the input shaft had zero shims from the factory!) as well as make some seal drivers on my lathe out of Delrin to properly install any seals I replace. I'll machine any shims I need as well.

I can get a metric depth micrometer, but the BMW special bolt-on shimming measurement tool (BMW No. 23 4 600) is unobtanium. The service manual states that it's exactly 60mm above the level of the gasket surface. Anybody got any good ideas as to what can substitute for the special tool and doesn't cost a fortune?

So far my best guesses have been a pair of identical gage blocks on two sides of the gasket surface and a precision straight edge between them, placing the micrometer above each bearing in turn, but then I'd have to account for the deflection of the straight edge.

I wonder what the manufacturing tolerance of the BMW tool is. If I knew that, it'd help me figure out how precise a substitute needs to be.

If I'm going to crack it open again, though, I'll re-shim all the transmission shafts properly (the input shaft had zero shims from the factory!) as well as make some seal drivers on my lathe out of Delrin to properly install any seals I replace. I'll machine any shims I need as well.

I can get a metric depth micrometer, but the BMW special bolt-on shimming measurement tool (BMW No. 23 4 600) is unobtanium. The service manual states that it's exactly 60mm above the level of the gasket surface. Anybody got any good ideas as to what can substitute for the special tool and doesn't cost a fortune?

So far my best guesses have been a pair of identical gage blocks on two sides of the gasket surface and a precision straight edge between them, placing the micrometer above each bearing in turn, but then I'd have to account for the deflection of the straight edge.

I wonder what the manufacturing tolerance of the BMW tool is. If I knew that, it'd help me figure out how precise a substitute needs to be.

senseamidmadness

Neglected Bike Adopter

Wanted to post a minor update on this, for anybody else who ends up doing the wave washer modification in the future.

I can confirm now after a few more thousand miles that there is definitely increased transmission noise in neutral, and only when idling. It's a gear chatter (an audible clack-a-clack-a-clack-a-clack) that's constant when the clutch is not in use. Pulling the clutch lever completely quiets it. I can just barely hear it with my helmet and earplugs on.

Outside of neutral there's no change from the usual Oilhead transmission noises, and the gear clack is not present.

My choice to experiment with 85w-140 gear oil in this particular M97 hasn't been great. Shifting is harder, especially when cold. I'm going to go back to something thinner; might try out 75w-140 or mix this heavy stuff I already have with some synthetic 75w-90 to thin it out.

I can confirm now after a few more thousand miles that there is definitely increased transmission noise in neutral, and only when idling. It's a gear chatter (an audible clack-a-clack-a-clack-a-clack) that's constant when the clutch is not in use. Pulling the clutch lever completely quiets it. I can just barely hear it with my helmet and earplugs on.

Outside of neutral there's no change from the usual Oilhead transmission noises, and the gear clack is not present.

My choice to experiment with 85w-140 gear oil in this particular M97 hasn't been great. Shifting is harder, especially when cold. I'm going to go back to something thinner; might try out 75w-140 or mix this heavy stuff I already have with some synthetic 75w-90 to thin it out.

senseamidmadness

Neglected Bike Adopter

I've had good luck with the Bel-Ray "Gear Saver" 85W-140, GL-4 and GL-5 rated, NOT for wet clutches.

I haven't tried their 80-90 or thumper oils.

That Bel-Ray is exactly what's in it. I think my particular transmission just doesn't like it, and I've heard that the 6-speeds get along better with thicker gear oil than the 5-speeds.

pauls1150

MOA #24991, south of Los Angeles

My '04 6-speed likes it; I don't think it made any difference when I tried it in my '97 5-speed (I had notified my local shop that it didn't seem to be shifting correctly, so the first suggestion was to try some other oil), but that era of trannys did have "issues" from the factory: mine was replaced under warranty.

(Side note - I have tried "thicker" stuff in the '04, but it was more difficult to shift smoothly until it got hot.)

(Side note - I have tried "thicker" stuff in the '04, but it was more difficult to shift smoothly until it got hot.)

jammess

Jammess

My '04 6-speed likes it; I don't think it made any difference when I tried it in my '97 5-speed (I had notified my local shop that it didn't seem to be shifting correctly, so the first suggestion was to try some other oil), but that era of trannys did have "issues" from the factory: mine was replaced under warranty.

(Side note - I have tried "thicker" stuff in the '04, but it was more difficult to shift smoothly until it got hot.)

I have the original M93 trans in my '93 R1100RSL and have been using Motul 80w90 mineral gear box oil with the molybdenum additive (Mo52) for several years. The M93 used to rattle up a storm when fully warmed up at idle on the center stand but now it has no rattle and shifts smooth as any BMW transmission I've had from airheads to my '04 R1150RT which I sold in '16. Buy the Motul on Amazon. Use 80w90 Valvoline mineral in the FD. I should mention that the '93 R1100 only has just 13K original miles all put on by me since 2012 so I can't really comment on M93 longevity over time. I'll take an early R1100 over the 1150 any time for numerous reasons the transmission being one big reason to say nothing of the trans input shaft splines as in just keep them clean and lubricated on the 1100 series.

Last edited:

senseamidmadness

Neglected Bike Adopter

Not-so-good news.

I changed out the transmission oil again last night as I haven't liked what the Bel-Ray 85w-140 felt like, especially when cold.

The oil came out chocolate brown, with a golden metallic sheen, and there was quite a bit of material on the drain plug magnet with some shiny flakes that were too small to feel. I checked my maintenance log and this oil has only been in for 2,000 miles since the transmission bearing repair.

I put some 80w-90 Lucas conventional in as it's what I had on hand. Bike currently has around 40,800 miles and I'm planning on changing the transmission oil again at 42,000 along with a general service. If it comes out looking bad again I'll have to dive back into the transmission.

Any ideas as to what would be continuing the problem despite my wave washer fix and bearing replacement? I have a theory that this transmission was never properly shimmed from the factory, but I'm no expert.

I changed out the transmission oil again last night as I haven't liked what the Bel-Ray 85w-140 felt like, especially when cold.

The oil came out chocolate brown, with a golden metallic sheen, and there was quite a bit of material on the drain plug magnet with some shiny flakes that were too small to feel. I checked my maintenance log and this oil has only been in for 2,000 miles since the transmission bearing repair.

I put some 80w-90 Lucas conventional in as it's what I had on hand. Bike currently has around 40,800 miles and I'm planning on changing the transmission oil again at 42,000 along with a general service. If it comes out looking bad again I'll have to dive back into the transmission.

Any ideas as to what would be continuing the problem despite my wave washer fix and bearing replacement? I have a theory that this transmission was never properly shimmed from the factory, but I'm no expert.

senseamidmadness

Neglected Bike Adopter

Ah, I had forgotten about that, and there's a new bearing in there. The oil didn't smell burnt like it used to. Just smelled like classic stinky gear oil.

Any guesses as to the metallic sheen and magnet flakes? My only theory is that maybe the super-heavy gear oil wasn't getting to all the places it needed to when the transmission was cold.

Any guesses as to the metallic sheen and magnet flakes? My only theory is that maybe the super-heavy gear oil wasn't getting to all the places it needed to when the transmission was cold.

AntonLargiader

Active member

Going back to the diagrams about the M97 gear and bearing setup (links on page 2), you can see that having the largest possible inner race is important because it gives you more surface area between the gear and the bearing. I use bearings with the largest inner races I can find. Your pics make it look like the TM204 race might be a bit smaller than what was there before.

This whole thing is a design oversight that became a design flaw. In the M93/M94 days the bearing was a tapered roller, with a massively wide inner race that had plenty of bearing surface for the gear. The chamfer on the gear just didn't matter and maybe even helped in some way. When BMW abandoned the tapered rollers in '96 they went with the original orange "Clean bearings" with LU suffixes, and those bearings became retroactive for M93/94 repairs. It was only some years later, AFAIK, that BMW started selling the M94 gear without the chamfer. I guess they first had to use up all of the chamfered gears on M97-based production (creating a bunch of time bombs). They never sold parts for M97 shafts but anyone who worked with these things knew it was the M94 gear so it was great to see the non-chamfered gears show up.

The original rear clean bearing, the -520 bearing, I might still have one around and it would be interesting to see if it has a larger inner race than the -867 bearing. Maybe that's what you removed. After the 1150s came out, actually around the time they were being replaced by the 1200s, BMW started superseding those style bearings back into the older designs and that's how we got the TM204 back there. The -176 6-speed front input bearing got substituted into the 5-speed output shaft the same way (and holy moly it's called for all the way back to WW2-era pressed-together cranks!).

This whole thing is a design oversight that became a design flaw. In the M93/M94 days the bearing was a tapered roller, with a massively wide inner race that had plenty of bearing surface for the gear. The chamfer on the gear just didn't matter and maybe even helped in some way. When BMW abandoned the tapered rollers in '96 they went with the original orange "Clean bearings" with LU suffixes, and those bearings became retroactive for M93/94 repairs. It was only some years later, AFAIK, that BMW started selling the M94 gear without the chamfer. I guess they first had to use up all of the chamfered gears on M97-based production (creating a bunch of time bombs). They never sold parts for M97 shafts but anyone who worked with these things knew it was the M94 gear so it was great to see the non-chamfered gears show up.

The original rear clean bearing, the -520 bearing, I might still have one around and it would be interesting to see if it has a larger inner race than the -867 bearing. Maybe that's what you removed. After the 1150s came out, actually around the time they were being replaced by the 1200s, BMW started superseding those style bearings back into the older designs and that's how we got the TM204 back there. The -176 6-speed front input bearing got substituted into the 5-speed output shaft the same way (and holy moly it's called for all the way back to WW2-era pressed-together cranks!).

senseamidmadness

Neglected Bike Adopter

I see what you mean -- even with the wave washer removed and replaced with a solid washer, the input shaft gear can still move under torque and tap the inner race of the bearing. Removing the wave washer, in theory, would just change/increase the amount of force it takes to do that. I didn't replace the gear with the updated design and I was mildly worried about that. Should've just done it when I had the thing open.

On the positive side, I have a small metal lathe and access to a multiprocess welder, and I happened to receive two bearings when I ordered that replacement 6304LLU. If and when I open up the transmission again, probably in the near future, I can modify the gear I have to remove that chamfer. I'd either have it built up with additional filler metal and machine and file it to copy the updated design, or possibly cut and bore a deeper groove and machine a mild steel repair sleeve that's a press fit and matches the existing ID. That should fix it properly, right?

I'll definitely be measuring it for shim changes too since it doesn't behave nearly as well as my RT's M97 does.

On the positive side, I have a small metal lathe and access to a multiprocess welder, and I happened to receive two bearings when I ordered that replacement 6304LLU. If and when I open up the transmission again, probably in the near future, I can modify the gear I have to remove that chamfer. I'd either have it built up with additional filler metal and machine and file it to copy the updated design, or possibly cut and bore a deeper groove and machine a mild steel repair sleeve that's a press fit and matches the existing ID. That should fix it properly, right?

I'll definitely be measuring it for shim changes too since it doesn't behave nearly as well as my RT's M97 does.

Similar threads

- Replies

- 18

- Views

- 14K

- Replies

- 7

- Views

- 1K

- Replies

- 5

- Views

- 2K