DSXMachina

Member

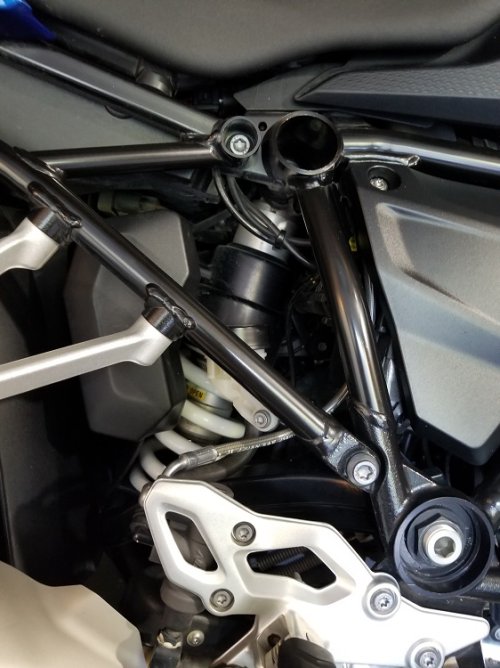

FWIW I'm in the automotive industry, and came from the fabricated machine tool industry. I have both welded and specified welds, Your welds (and the similar welds on my '18 1250RT) are as 'sloppy' as they get. No doubt there's sufficient penetration and bond, but aesthetically they're poor quality. They are so poor that in fact it it doubtful that they are done robotically. You want to see a 'perfect' weld, find a robotic weld.

The OP is right. BMW can and should do better. Just because.

The OP is right. BMW can and should do better. Just because.