professorb

Iron Butt Patriot

At the risk of revealing my sometimes obsessive OCD nature, I ask this community to comment -- and to possibly display your own evidence -- upon the quality of various frame welds on their bikes.

I have to say, I LOVE my brand-new 2021 R1250RT Sport (Racing Blue Metallic, the fastest color)! Yes, I have a myriad of issues with the TFT display's lack of cooperation with my iPhone, but those problems will be exorcised in a different sub forum on a different day.

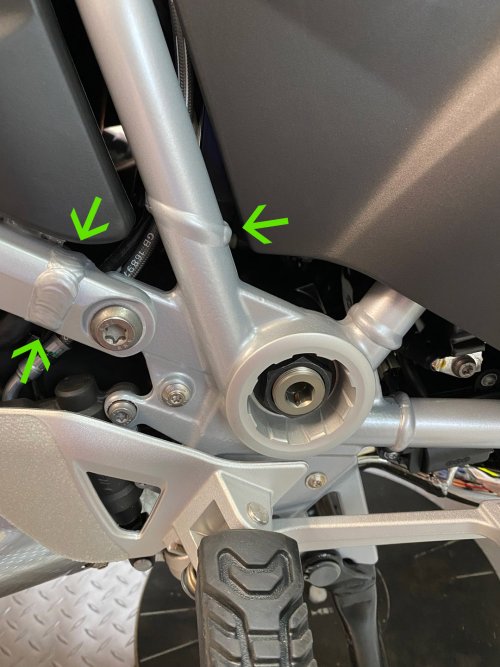

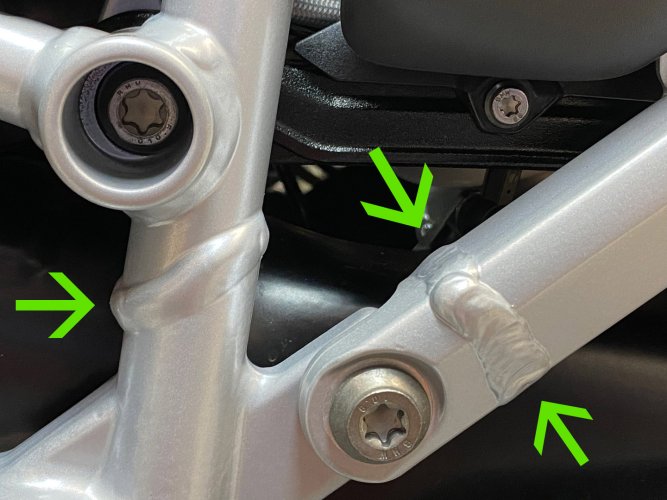

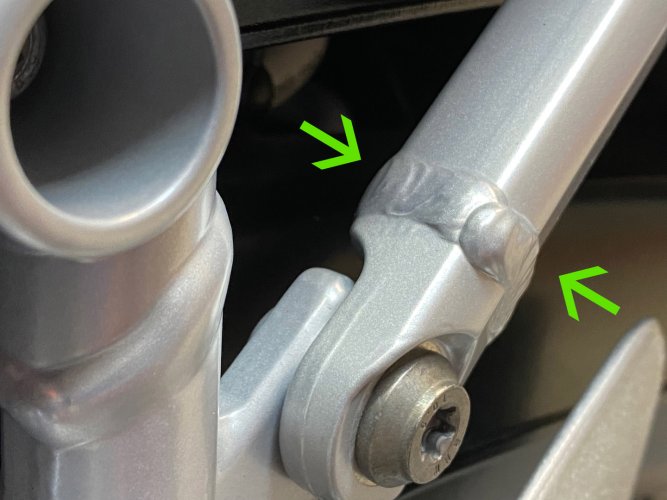

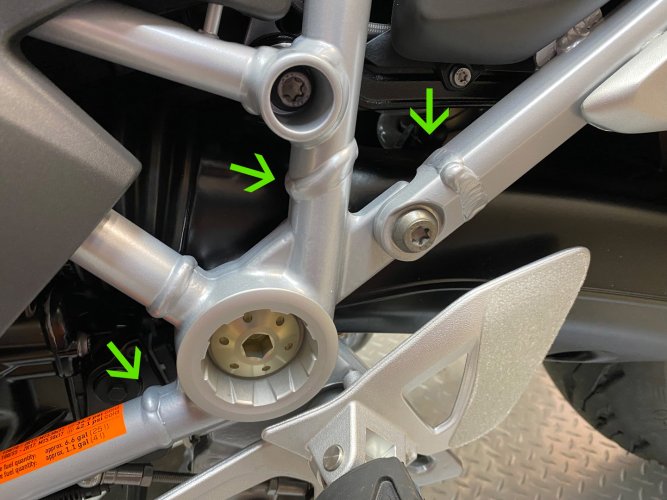

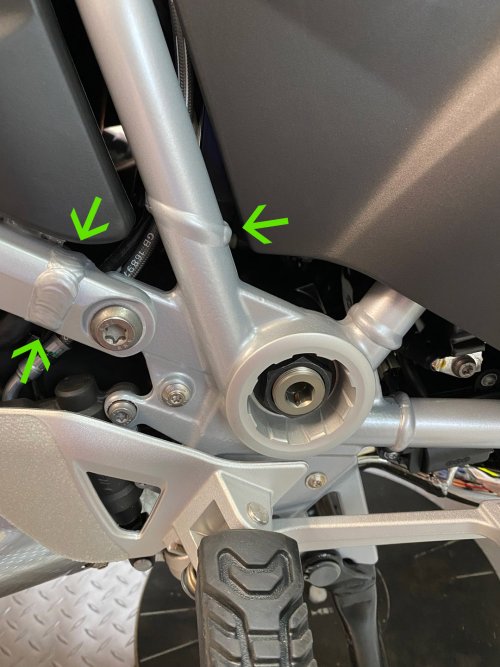

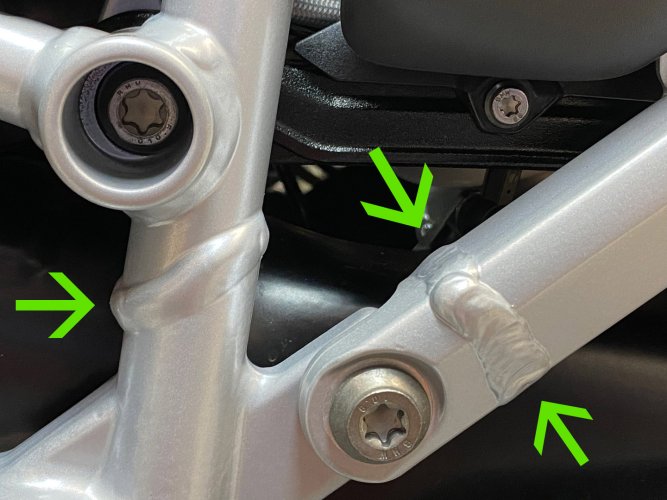

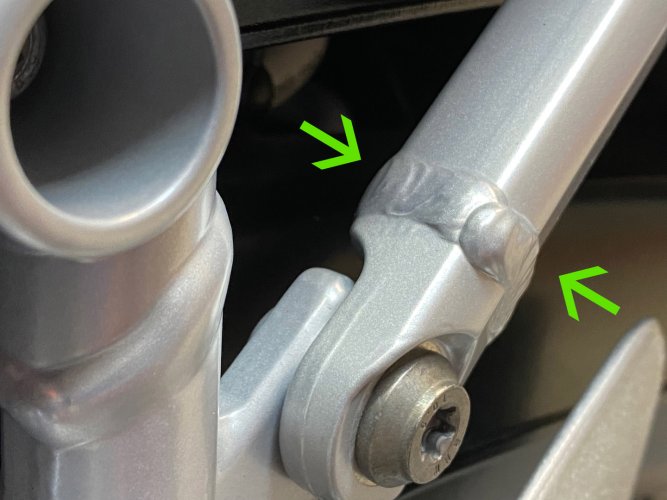

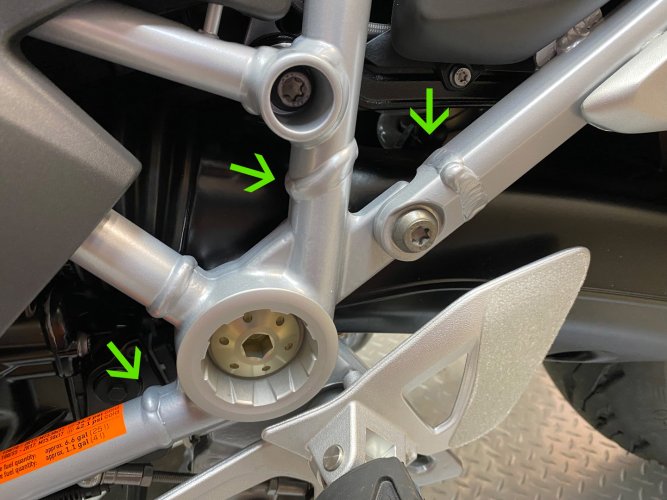

My only true disappointment with this new machine are the quality of the (most visible) welds on the main frame assembly.

I am attaching a few pictures showing what I have... and I must say, having owned a lot of motorcycles over the years, I have never seen such cobby-looking, "gloopy" welds on any other high-end Moto. True, this is my first BMW, so I might be overreacting to something that is commonly accepted as "normal" within the community. Yet, on a $27,000.-plus "state-of-the-art" motorcycle, this level of work seems way out of place.

I have shared these images and concerns with BMW, and they have been responsive, polite, and protective in their comments. It has been suggested that I take the issue to my Dealer, which I have casually done, but what can they do about this? The Dealer did not build the bike. BMW builds the machines, and it is their Quality Assurance that lets this work leave the factory floor.

So, am I being an OCD wonk, or is this really something worth getting worked up over? What do your welds look like? Should I press for a "fix" (whatever that might be -- I really can not imagine how to correct this?)... of should I just shut up and ride?

Show me those welds!! . THANKS!

. THANKS!

I have to say, I LOVE my brand-new 2021 R1250RT Sport (Racing Blue Metallic, the fastest color)! Yes, I have a myriad of issues with the TFT display's lack of cooperation with my iPhone, but those problems will be exorcised in a different sub forum on a different day.

My only true disappointment with this new machine are the quality of the (most visible) welds on the main frame assembly.

I am attaching a few pictures showing what I have... and I must say, having owned a lot of motorcycles over the years, I have never seen such cobby-looking, "gloopy" welds on any other high-end Moto. True, this is my first BMW, so I might be overreacting to something that is commonly accepted as "normal" within the community. Yet, on a $27,000.-plus "state-of-the-art" motorcycle, this level of work seems way out of place.

I have shared these images and concerns with BMW, and they have been responsive, polite, and protective in their comments. It has been suggested that I take the issue to my Dealer, which I have casually done, but what can they do about this? The Dealer did not build the bike. BMW builds the machines, and it is their Quality Assurance that lets this work leave the factory floor.

So, am I being an OCD wonk, or is this really something worth getting worked up over? What do your welds look like? Should I press for a "fix" (whatever that might be -- I really can not imagine how to correct this?)... of should I just shut up and ride?

Show me those welds!!

(Do not exceed three layers, as it will over stiffen the frame and confuse the ESA and render the bike unrideable.)

(Do not exceed three layers, as it will over stiffen the frame and confuse the ESA and render the bike unrideable.)