2dflier

New member

Hey all. I've had the RT since 62K. It now has 84K. A couple of weeks ago I found some play in the rear end. The dealer advised I bring in the crown gear for wheel bearing replacement. I don't know how reliable a check this is but I didn't detect any play in the bearing by pulling on the tapered bearing end of the gear and it seems to roll smoothly enough (spinning crown gear and nothing noticeable while riding or rotating the rear end before removing the wheel). I did find pivot bearing free play. The outboard pivot bearing was brinnelled and not rotating freely so I removed both and thought my trouble would be limited to just the pivot bearings.

Before reinstalling the crown gear I inspected the crown gear tapered roller bearing and found all the rollers damaged basically across the entire width and circumference of all rollers. The cup is also pitted in the bottom third or so. I don't know if the damage is spalling or roll over damage but it needs to be replaced. I'm on the 3rd or 4th FD fluid change since I've had the bike and in each case the mag plug only showed dark fine stuff, no sparklies. So I assume the bearings have been dieing a slow death.

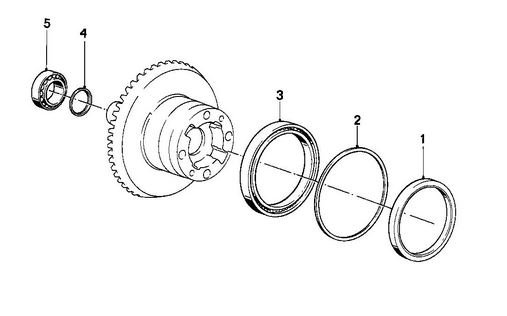

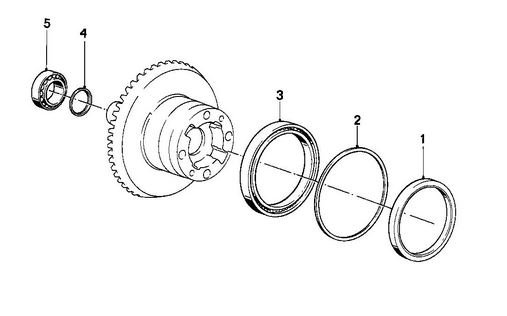

The question is how should I proceed? If I could figure out how to remove the tapered cup from the housing can and should I just replace the bearing set? Can this bearing be replaced without reshimming? I'm assuming the tapered bearing shim (item 4) is primarily to set gear lash and the inner shim (item 2) sets preload. If initial preload is suspect in the bearing damage I'm guessing I should have the entire thing rebuilt correctly.

So can I replace the tapered bearing? If so how do I remove the cup from the housing?

If it should be rebuilt should I contact Mr Cutter or are their good options in the Raleigh area? Bombar's Beemers are in Durham but I know nothing about them.

Thanks much for the help.

Before reinstalling the crown gear I inspected the crown gear tapered roller bearing and found all the rollers damaged basically across the entire width and circumference of all rollers. The cup is also pitted in the bottom third or so. I don't know if the damage is spalling or roll over damage but it needs to be replaced. I'm on the 3rd or 4th FD fluid change since I've had the bike and in each case the mag plug only showed dark fine stuff, no sparklies. So I assume the bearings have been dieing a slow death.

The question is how should I proceed? If I could figure out how to remove the tapered cup from the housing can and should I just replace the bearing set? Can this bearing be replaced without reshimming? I'm assuming the tapered bearing shim (item 4) is primarily to set gear lash and the inner shim (item 2) sets preload. If initial preload is suspect in the bearing damage I'm guessing I should have the entire thing rebuilt correctly.

So can I replace the tapered bearing? If so how do I remove the cup from the housing?

If it should be rebuilt should I contact Mr Cutter or are their good options in the Raleigh area? Bombar's Beemers are in Durham but I know nothing about them.

Thanks much for the help.