jimbob1960

New member

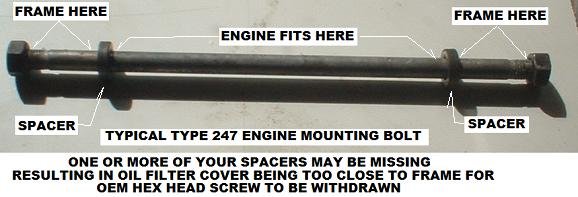

Just did my first airhead tune up, including oil/filter change....read all the advice, had extra shims, 2 piece filter, new white o-ring, etc, etc. The hex head bolts were not an issue coming out, but goodness, that upper M6 socket head? How much engineering went into designing the frame/engine relationship so that on a good day, if the planets align and you hold your mouth right (and have a small enough pair of needle nose to grab the outside and make 1/128th of a revolution...), one can BARELY get the thing out. No wonder people cut these o-rings!

To add to the amount of sample data out there, my oil filter "factor" was about 3.9 MM. The o-ring that came out (with 1 shim, and the paper gasket in place) was just barely flattened on one side, more so on the other. Replaced the shim with a new one, and removed the paper gasket from the stack...had observable "rebound" on the cap with the fasteners drawn down to within a few thou of the cover being seated. The old shim was beat up, and didn't look like the new ones. Kinda looked homemade. It mikes about .25 MM, where as the new one was .3 MM. No leaks, and the oil pressure light went out within three seconds of starting to crank.

JimBob

-----------------

1980 R100RT

1978 SR500

1971 Rokon RT-140

(and my wife's Honda Airblade in Saigon)

To add to the amount of sample data out there, my oil filter "factor" was about 3.9 MM. The o-ring that came out (with 1 shim, and the paper gasket in place) was just barely flattened on one side, more so on the other. Replaced the shim with a new one, and removed the paper gasket from the stack...had observable "rebound" on the cap with the fasteners drawn down to within a few thou of the cover being seated. The old shim was beat up, and didn't look like the new ones. Kinda looked homemade. It mikes about .25 MM, where as the new one was .3 MM. No leaks, and the oil pressure light went out within three seconds of starting to crank.

JimBob

-----------------

1980 R100RT

1978 SR500

1971 Rokon RT-140

(and my wife's Honda Airblade in Saigon)