fredheiler@aol.com

Member

In 1969, there were no Japanese superbikes, and I wanted a BMW that would keep up with my pals' Nortons, Triumphs and Harleys. As a result, I build a VW-powered R60/2 that I still own and ride; it's smoother than stock, obviously very fast and still under 500 pounds..

More than an engine-transmission adaptor and frame mods, a tall-geared trans was essential to the success of this wacky project. While the stock /2 bike does about 4,000 rpm in 4th gear at 60 mph, I needed to cut that engine speed in half on the highway, both to keep it cool and to make good use of the extra torque. After researching BMW final drives, I was disappointed to learn there was nothing much taller, not even on the racing bikes.

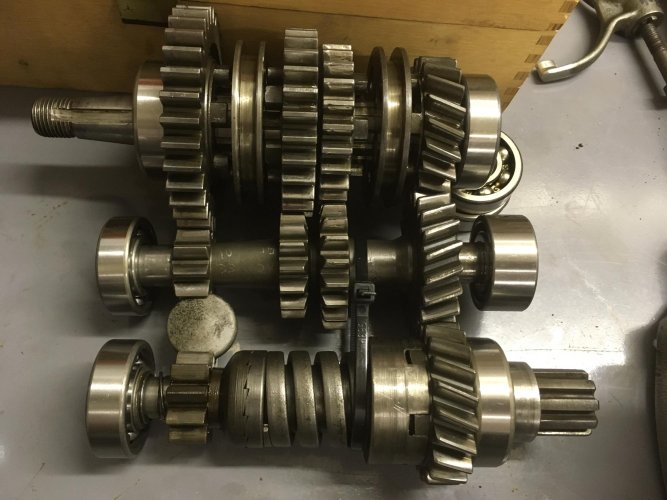

As a result, I replaced the small drive gear on the transmission input shaft with a larger one (an extra 4th gear from the output shaft; changed the input gear ratio from 1.5:1 to about 1:1, making all four gears much taller). To do this, I had to relocate the cluster shaft so it was further from the input shaft, but was still the same distance from the output shaft (see attached "shafts" photo). To do this, I welded up the cluster bearing bores in the box and the cover, then re-bored them (see attached "cover" photo). I was lucky to use two excellent machinists, because the backlash on all the gears feels absolutely the same as stock! I wish I could take credit for this design, but it actually came from a guy who lived near Danbury, CT (can't recall his name).

In 50-plus years of riding this machine, the trans has been nearly bulletproof, despite transmitting 2-3 times the engine torque -- one bearing failure, which I caught before it did any major damage (I probably screwed up end play), and two spun output shaft flanges, the weak point of the gearbox. First, I replaced the keyed flange with the stronger non-keyed one, and now run a flange with two large keys, which has been fine for at least 20,000 miles now.

One postscript: initially, the new ratio of first gear was somewhere between the old second and third, which was tough to deal with in traffic. Somewhere I found a set of sidecar gears that use lower (higher numerically) first, second and third gears, which work well in this odd application. The result is a wide-ratio transmission that feels perfect from a stop light to about 145 mph. I know there are much faster bikes these days, but perhaps this project will help someone modifying a later BMW.

More than an engine-transmission adaptor and frame mods, a tall-geared trans was essential to the success of this wacky project. While the stock /2 bike does about 4,000 rpm in 4th gear at 60 mph, I needed to cut that engine speed in half on the highway, both to keep it cool and to make good use of the extra torque. After researching BMW final drives, I was disappointed to learn there was nothing much taller, not even on the racing bikes.

As a result, I replaced the small drive gear on the transmission input shaft with a larger one (an extra 4th gear from the output shaft; changed the input gear ratio from 1.5:1 to about 1:1, making all four gears much taller). To do this, I had to relocate the cluster shaft so it was further from the input shaft, but was still the same distance from the output shaft (see attached "shafts" photo). To do this, I welded up the cluster bearing bores in the box and the cover, then re-bored them (see attached "cover" photo). I was lucky to use two excellent machinists, because the backlash on all the gears feels absolutely the same as stock! I wish I could take credit for this design, but it actually came from a guy who lived near Danbury, CT (can't recall his name).

In 50-plus years of riding this machine, the trans has been nearly bulletproof, despite transmitting 2-3 times the engine torque -- one bearing failure, which I caught before it did any major damage (I probably screwed up end play), and two spun output shaft flanges, the weak point of the gearbox. First, I replaced the keyed flange with the stronger non-keyed one, and now run a flange with two large keys, which has been fine for at least 20,000 miles now.

One postscript: initially, the new ratio of first gear was somewhere between the old second and third, which was tough to deal with in traffic. Somewhere I found a set of sidecar gears that use lower (higher numerically) first, second and third gears, which work well in this odd application. The result is a wide-ratio transmission that feels perfect from a stop light to about 145 mph. I know there are much faster bikes these days, but perhaps this project will help someone modifying a later BMW.

Attachments

Last edited: