Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome, Guest! We hope you enjoy the excellent technical knowledge, event information and discussions that the BMW MOA forum provides. Some forum content will be hidden from you if you remain logged out. If you want to view all content, please click the 'Log in' button above and enter your BMW MOA username and password. If you are not an MOA member, why not take the time to join the club, so you can enjoy posting on the forum, the BMW Owners News magazine, and all of the discounts and benefits the BMW MOA offers?

-

Beginning April 1st, and running through April 30th, there is a new 2024 BMW MOA Election discussion area within The Club section of the forum. Within this forum area is also a sticky post that provides the ground rules for participating in the Election forum area. Also, the candidates statements are provided. Please read before joining the conversation, because the rules are very specific to maintain civility.

The Election forum is here: Election Forum

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

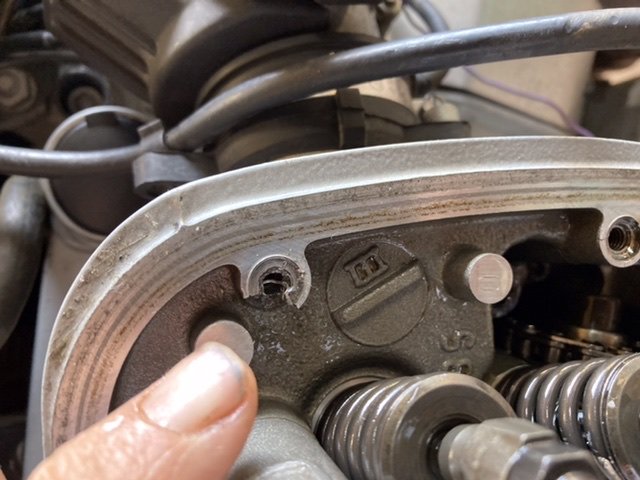

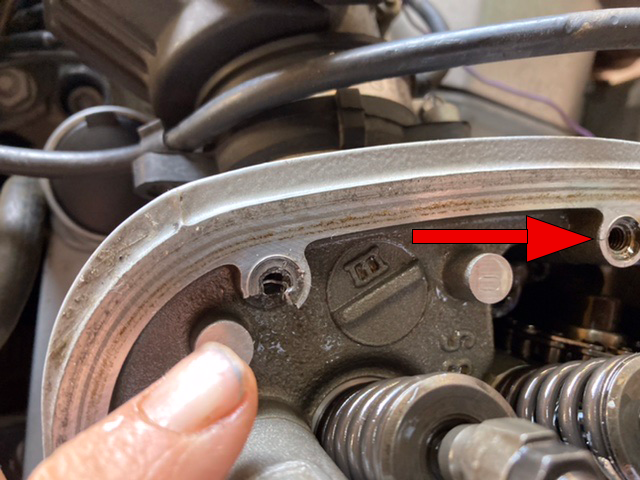

Found out why I have an oil leak.

- Thread starter eastbay

- Start date

52184

GTRider

Pull the head, have a machine shop do a weld buildup to replace the missing material including the threaded hole, and remachine the hole and do a very light skim cut on the mating surface.

It’s not a good candidate for in situ repair nor bodging up with epoxies and such as I’m sure someone will recommend.

Best,

DeVern

It’s not a good candidate for in situ repair nor bodging up with epoxies and such as I’m sure someone will recommend.

Best,

DeVern

dieselyoda

Active member

Pull the head, have a machine shop do a weld buildup to replace the missing material including the threaded hole, and remachine the hole and do a very light skim cut on the mating surface.

It’s not a good candidate for in situ repair nor bodging up with epoxies and such as I’m sure someone will recommend.

Best,

DeVern

But....A very highly skilled welder using a 0.50mm torch tip on their TIG and 100% Argon with a 6mm carbon down the centre could come close to machine shop quality.

Totally agree, never seen an epoxy/liquid metal or even low melt aluminum solder stand up.

I was able to insert a helicoil and was able to tighten bolt to spec. fingers crossed.

Finish the job with a liberal (or conservative, depending on political leaning) coating of JB Weld.

Yes, I'm kidding.

Hope the helicoil works out!

If the helicoil does not work, another attempt could be made with a time-sert. The helicoil is a coil of square cross section wire whereas the time-sert is a bushing the has threads on the inside and outside of the bush.

https://www.amazon.com/TIME-SERT-M6...keywords=time+serts+kit&qid=1655061950&sr=8-3

https://www.amazon.com/TIME-SERT-M6...keywords=time+serts+kit&qid=1655061950&sr=8-3

pglaves

#13338

The capscrews that engage those holes are "shoulder bolts". Then snug to the shoulder and no tighter. They need to be snug enough to keep from falling out. That is their job. The valve cover simply rides on the compressed rubber retainers on each bolt and the rubber gasket(s). A Helicoil will hold here just fine. I have used them to repair this damage at least a half dozen times.

tHANKS, The damage was most likely caused by overtightening.The capscrews that engage those holes are "shoulder bolts". Then snug to the shoulder and no tighter. They need to be snug enough to keep from falling out. That is their job. The valve cover simply rides on the compressed rubber retainers on each bolt and the rubber gasket(s). A Helicoil will hold here just fine. I have used them to repair this damage at least a half dozen times.

dieselyoda

Active member

If the helicoil does not work, another attempt could be made with a time-sert. The helicoil is a coil of square cross section wire whereas the time-sert is a bushing the has threads on the inside and outside of the bush.

https://www.amazon.com/TIME-SERT-M6...keywords=time+serts+kit&qid=1655061950&sr=8-3

View attachment 88162

A proper install of a Time-Sert is a definite option if you choose not to weld.

Follow the instructions and use Loctite Cylinder mount.

Because you will be creating some swarf, liberally use grease around your work to catch the swarf.

Wash with Brak-Clean and compressed air.

senseamidmadness

Neglected Bike Adopter

A Time-Sert is exactly what I would've thought of for that hole, since it's effectively replacing the missing spot. Happy to hear a Heli-Coil worked well enough to hold.

Thankfully nobody suggested JB -- while it does have plenty of emergency uses, it's pretty bad for making bolt threads. Ari Henning of Revzilla tested it in a Youtube video, and an M6 thread tapped into JB-Weld only held 3.5 foot pounds versus 14 for a Time-Sert and 20 for both Heli-Coil and a tapped hole in aluminum.

Thankfully nobody suggested JB -- while it does have plenty of emergency uses, it's pretty bad for making bolt threads. Ari Henning of Revzilla tested it in a Youtube video, and an M6 thread tapped into JB-Weld only held 3.5 foot pounds versus 14 for a Time-Sert and 20 for both Heli-Coil and a tapped hole in aluminum.

gsaddict

Pepperfool

tHANKS, The damage was most likely caused by overtightening.

Sadly, always is.

Hand tighten until the shoulder seats. Stop.

No need for a torque wrench.

Similar threads

- Replies

- 9

- Views

- 354