rxcrider

New member

I have a 1995 R1100RS wearing RSL clothes, the history of which I know little of. Working on the bike is sort of a history lesson as I find what has been done to it previously. It has 80,605 miles on the clock and not knowing when the splines were last touched, I decided to lube everything behind the gear box and swap out the FD pivot bearings which were developing some play at the same time. The drive shaft splines were more than adequately lubed with moly grease and were in great shape. The rear u-joint had a bit of play so the low mileage drive shaft from the 1996 parts bike is going into service. I wanted to wait ‘til winter to pull the gear box and lube the clutch / input spline, but I figured as long as I was this far, I should pull the starter and have a look, just in case. This is where things started to get interesting…

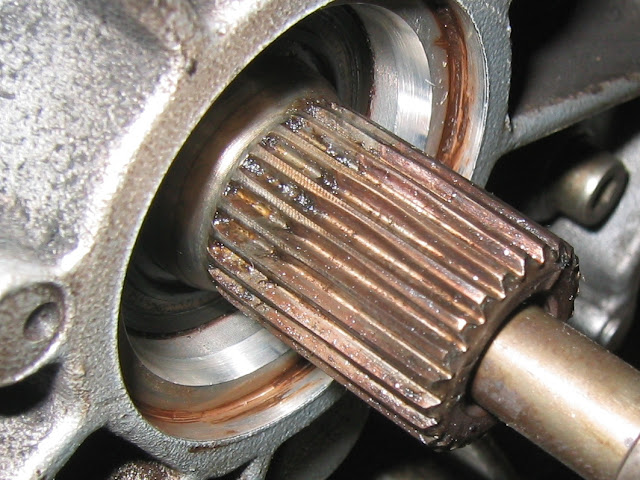

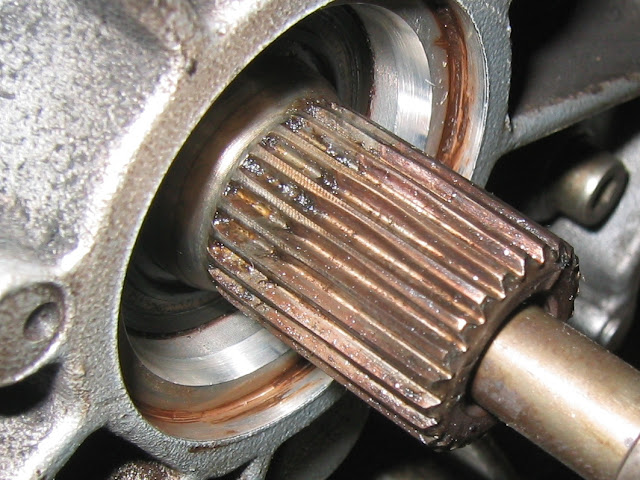

For starters, when I pulled the lever to release the clutch / friction disk, I found that it had a lot of play on the input shaft. I was looking at ~0.200” free play (rotational) at the OD of the friction material before the splines would grab on the input shaft! I figured it was time to pull the trans and figure out how much of a pain it is to swap an input shaft – thank goodness for the parts bike. When I got the thing slid apart, I was surprised to find an input shaft that was worn, but not completely roached.

I figured it was time to pull the trans and figure out how much of a pain it is to swap an input shaft – thank goodness for the parts bike. When I got the thing slid apart, I was surprised to find an input shaft that was worn, but not completely roached.

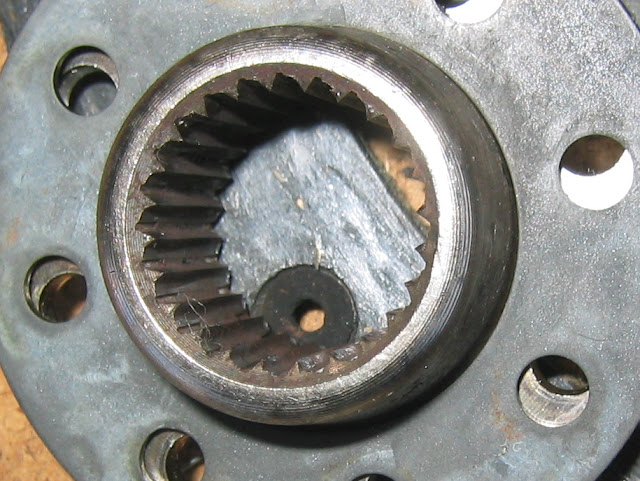

A glance at the mouth of the sandworm at the center of the clutch quickly told me where most of the play had been coming from.

Further disassembly of the clutch gave me a few pieces of good news. Fist off, the clutch had already been upgraded to the newer style assembly. The date on the clutch disk was 2004 and the part number of the pressure plate matched the newer parts drawing on Max. The friction material was only worn down to ~0.210” and I had spare clutch disk from the parts bike. It was the original 1996 part and had a 0.025” less friction material but also had a good looking hub. $33 and a day later, a local clutch shop has joined my 1996 hub with my 2004 disk and I’m starting to put her back together.

At this point, the transmission is back in with a thin coat of guard dog moly grease on the splines and hopefully things continue to go back together smoothly with no more surprises. I figure I’ll pull the starter a couple times a year and keep an eye on things. I did spring for the new bolts and washers. Yes, I’m being cheap, but now that I’ve done it once, pulling the trans really isn’t a big deal and a complete clutch assembly just isn’t in the budget at the moment. When the time comes to do this again, a complete clutch assembly and the input shaft from my spare M94 gearbox (cracked case from the accident) should put me back in good shape again.

Two things the installer of the replacement clutch may have done to help the wear along is only using a very small amount of non-moly grease on the input spline and clocking the flywheel, pressure plate and clutch cover such that the white marks were all grouped within a 90 degree sweep. Hopefully the "new" clutch hub combined with correcting these two issues will give me some time before I bite the bullet.

Another interesting note on this bike is that it has had an issue with pulling to the right since I first got on it. I found that the wheels were parallel, but that the rear was offset a little more that 0.125” to the left. I removed the rear wheel shim and most of the issue went away, but there are rumblings that it might not be such a good idea to do so and I have to think that if it were just there for an alignment purpose, it wouldn’t be on pretty much every model from that era with cast wheels. With that in mind, I found some washers with a 0.065” thickness and an OD that is just slightly larger than the head on the right hand pivot pins for the swing arm and FD. I opened up the ID on the washers to fit the two pins and with one on each pin, this should put me in just about perfect alignment.

Once I get the rear half of the bike back together, I have a front master cylinder to rebuild, brakes to bleed and fuel filters to replace.

In a few days, I guess I’ll know whether my decisions were good ones or not – in the short term, at least. If not, I now have experience in pulling a gear box.

If anyone else is playing with a clutch or drive shaft and needing to be cheap about it, I have a 1996 (old style) clutch assembly and flywheel with a 0.185" thick clutch disk(minus the hub) available. I also have a drive shaft with just a tiny bit of play in the rear joint. Neither is the greatest solution, but I'll keep them around 'cause it just might get someone (maybe even me) moving in a pinch. All it takes is a good hub and $33.

For starters, when I pulled the lever to release the clutch / friction disk, I found that it had a lot of play on the input shaft. I was looking at ~0.200” free play (rotational) at the OD of the friction material before the splines would grab on the input shaft!

I figured it was time to pull the trans and figure out how much of a pain it is to swap an input shaft – thank goodness for the parts bike. When I got the thing slid apart, I was surprised to find an input shaft that was worn, but not completely roached.

I figured it was time to pull the trans and figure out how much of a pain it is to swap an input shaft – thank goodness for the parts bike. When I got the thing slid apart, I was surprised to find an input shaft that was worn, but not completely roached.

A glance at the mouth of the sandworm at the center of the clutch quickly told me where most of the play had been coming from.

Further disassembly of the clutch gave me a few pieces of good news. Fist off, the clutch had already been upgraded to the newer style assembly. The date on the clutch disk was 2004 and the part number of the pressure plate matched the newer parts drawing on Max. The friction material was only worn down to ~0.210” and I had spare clutch disk from the parts bike. It was the original 1996 part and had a 0.025” less friction material but also had a good looking hub. $33 and a day later, a local clutch shop has joined my 1996 hub with my 2004 disk and I’m starting to put her back together.

At this point, the transmission is back in with a thin coat of guard dog moly grease on the splines and hopefully things continue to go back together smoothly with no more surprises. I figure I’ll pull the starter a couple times a year and keep an eye on things. I did spring for the new bolts and washers. Yes, I’m being cheap, but now that I’ve done it once, pulling the trans really isn’t a big deal and a complete clutch assembly just isn’t in the budget at the moment. When the time comes to do this again, a complete clutch assembly and the input shaft from my spare M94 gearbox (cracked case from the accident) should put me back in good shape again.

Two things the installer of the replacement clutch may have done to help the wear along is only using a very small amount of non-moly grease on the input spline and clocking the flywheel, pressure plate and clutch cover such that the white marks were all grouped within a 90 degree sweep. Hopefully the "new" clutch hub combined with correcting these two issues will give me some time before I bite the bullet.

Another interesting note on this bike is that it has had an issue with pulling to the right since I first got on it. I found that the wheels were parallel, but that the rear was offset a little more that 0.125” to the left. I removed the rear wheel shim and most of the issue went away, but there are rumblings that it might not be such a good idea to do so and I have to think that if it were just there for an alignment purpose, it wouldn’t be on pretty much every model from that era with cast wheels. With that in mind, I found some washers with a 0.065” thickness and an OD that is just slightly larger than the head on the right hand pivot pins for the swing arm and FD. I opened up the ID on the washers to fit the two pins and with one on each pin, this should put me in just about perfect alignment.

Once I get the rear half of the bike back together, I have a front master cylinder to rebuild, brakes to bleed and fuel filters to replace.

In a few days, I guess I’ll know whether my decisions were good ones or not – in the short term, at least. If not, I now have experience in pulling a gear box.

If anyone else is playing with a clutch or drive shaft and needing to be cheap about it, I have a 1996 (old style) clutch assembly and flywheel with a 0.185" thick clutch disk(minus the hub) available. I also have a drive shaft with just a tiny bit of play in the rear joint. Neither is the greatest solution, but I'll keep them around 'cause it just might get someone (maybe even me) moving in a pinch. All it takes is a good hub and $33.

Last edited: