bwanajames

New member

Greetings All,

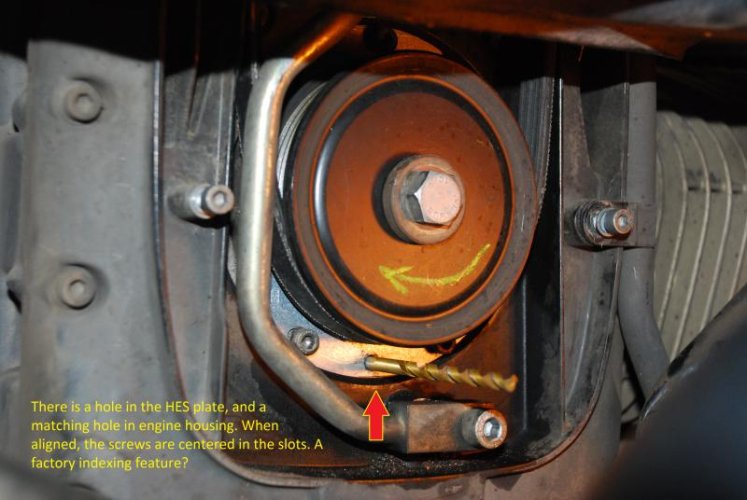

I've got a '96 R1100RT and as a preventative measure, have decided to replace the Hall Sensor. Now, my question is: How to best adjust the sensor base plate for proper ignition timing?

Before removing the old Hall sensor, I made a scribe mark next to the baseplate so at the very least, I could return the new one to the same position as the old. But, curious if there was a more accurate method, I snooped around the forums and found one suggesting that the timing/base plate position could be set using a voltmeter as described below:

"After replacing the sensor plate you will need to check the ignition timing, you can do this with the test rig above or with a voltmeter.

To test with a volt meter, plug the sensor plate in to the bike and switch on the ignition. Put the negative clip to a good earth on the frame and the positive probe to the Orange wire in the coupler (upper sensor). Watch the meter as you slowly turn the engine clockwise (viewed from the front).

Timing is correct when the voltage drops to zero with the OT (TDC) timing mark central in the window."

While this sounds simple enough, when my voltmeter needle drops, it is nowhere close to the OT (TDC) mark regardless of the baseplates position within the allowable latitude of the adjusting slot(s).

Has anybody tried and can verify this technique?

Additional Background:

1. The '96 1100's have, I understand, the 2.2 Motronic. While the 2.4 Motronic can be timed with the fuel pump cycle method, the 2.2 Motronic apparently cannot.

2. Before someone recommends the Dana Hager test box method, I've gone down to Radio Shack, purchased the components (which the clerk was kind enough to assemble) but unfortunately the LED's never illuminated. (Obviously an assembly error, but it looks good per the schematic...). So with a malfunctioning test box, I'm eager to validate the voltmeter method.

3. I understand some have had some success with a standard timing light (with initial advance being very close to the "S" mark...) if the rpms are at/below 1,000 (before the Motronic starts manipulating things...). But this method strikes me as problematic if the rpms aren't just right, so I haven't tried it.

Thanks,

Jim

I've got a '96 R1100RT and as a preventative measure, have decided to replace the Hall Sensor. Now, my question is: How to best adjust the sensor base plate for proper ignition timing?

Before removing the old Hall sensor, I made a scribe mark next to the baseplate so at the very least, I could return the new one to the same position as the old. But, curious if there was a more accurate method, I snooped around the forums and found one suggesting that the timing/base plate position could be set using a voltmeter as described below:

"After replacing the sensor plate you will need to check the ignition timing, you can do this with the test rig above or with a voltmeter.

To test with a volt meter, plug the sensor plate in to the bike and switch on the ignition. Put the negative clip to a good earth on the frame and the positive probe to the Orange wire in the coupler (upper sensor). Watch the meter as you slowly turn the engine clockwise (viewed from the front).

Timing is correct when the voltage drops to zero with the OT (TDC) timing mark central in the window."

While this sounds simple enough, when my voltmeter needle drops, it is nowhere close to the OT (TDC) mark regardless of the baseplates position within the allowable latitude of the adjusting slot(s).

Has anybody tried and can verify this technique?

Additional Background:

1. The '96 1100's have, I understand, the 2.2 Motronic. While the 2.4 Motronic can be timed with the fuel pump cycle method, the 2.2 Motronic apparently cannot.

2. Before someone recommends the Dana Hager test box method, I've gone down to Radio Shack, purchased the components (which the clerk was kind enough to assemble) but unfortunately the LED's never illuminated. (Obviously an assembly error, but it looks good per the schematic...). So with a malfunctioning test box, I'm eager to validate the voltmeter method.

3. I understand some have had some success with a standard timing light (with initial advance being very close to the "S" mark...) if the rpms are at/below 1,000 (before the Motronic starts manipulating things...). But this method strikes me as problematic if the rpms aren't just right, so I haven't tried it.

Thanks,

Jim