nevadaslim

New member

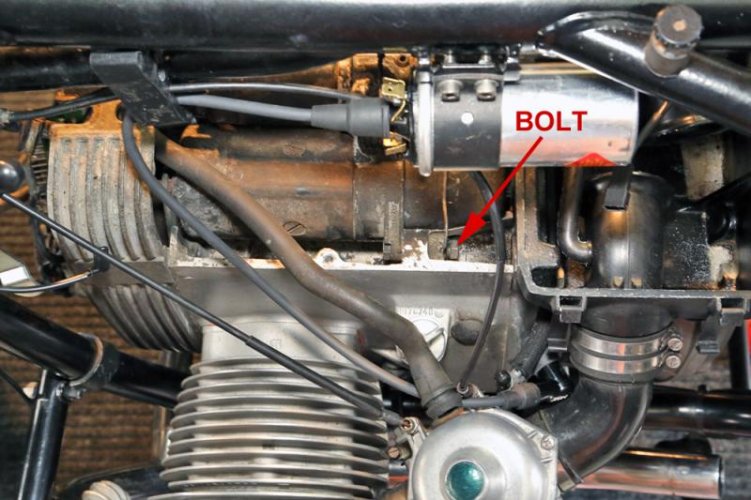

This question is for anyone who has replaced a R100 Airhead starter. Everything has gone smooth except for the two back bolts.

How did you get the bolt below(see photo), and the bolt on the other side out? What type of wrench did you use, brand, specially manufactured tool, ect. Where did you buy it? Sears, Home Depot, Lowes, Harbor Freight, ect?

Were you able to loosen the bolt-end, or the nut-end?

Thanks...

How did you get the bolt below(see photo), and the bolt on the other side out? What type of wrench did you use, brand, specially manufactured tool, ect. Where did you buy it? Sears, Home Depot, Lowes, Harbor Freight, ect?

Were you able to loosen the bolt-end, or the nut-end?

Thanks...

Attachments

Last edited: